Full-automatic battery adhesive tape pasting production line

A fully automatic, production line technology, applied to primary batteries, primary battery manufacturing equipment, battery assembly machines, etc., can solve the problems of high labor costs, low production efficiency, and low degree of full automation, so as to reduce production costs and improve production The Effect of Efficiency and Product Qualification Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

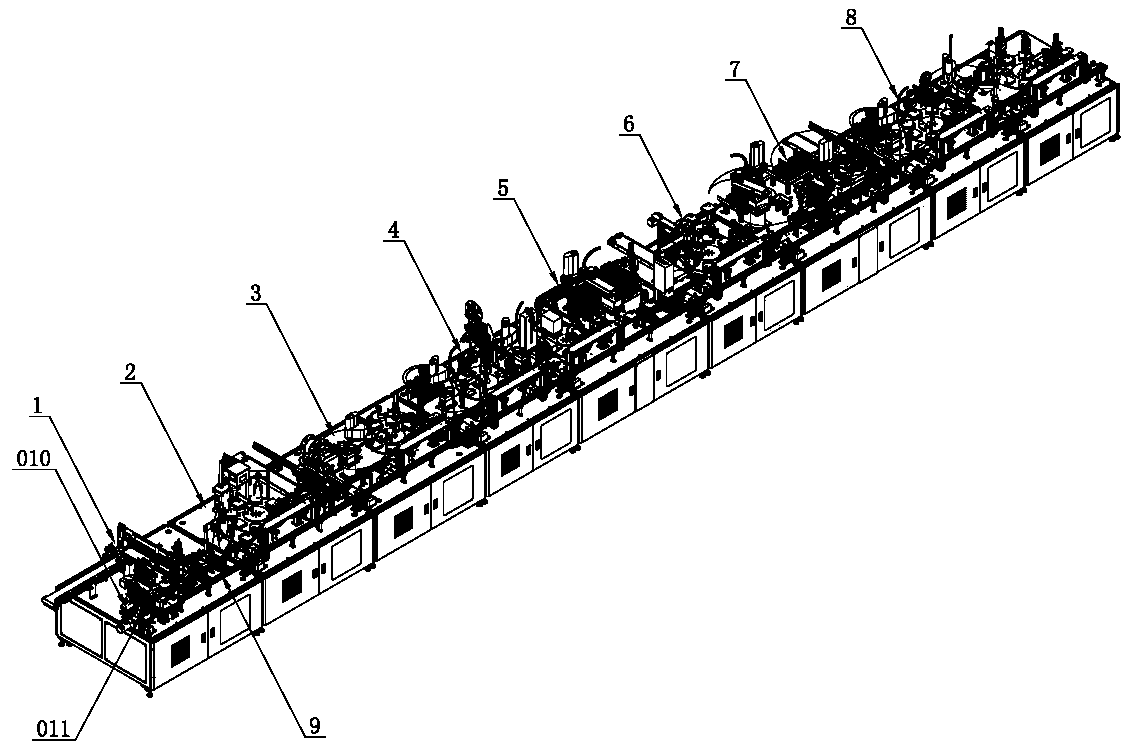

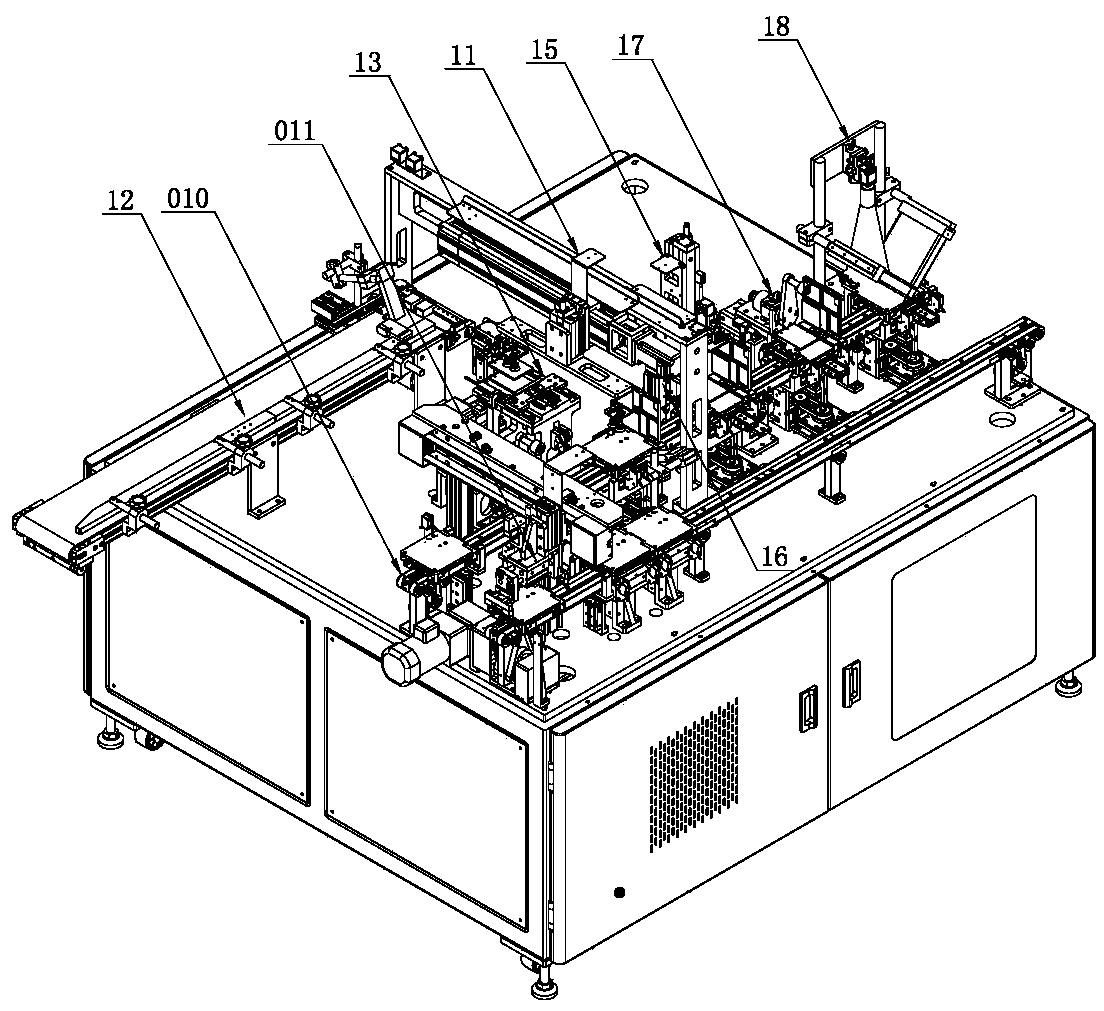

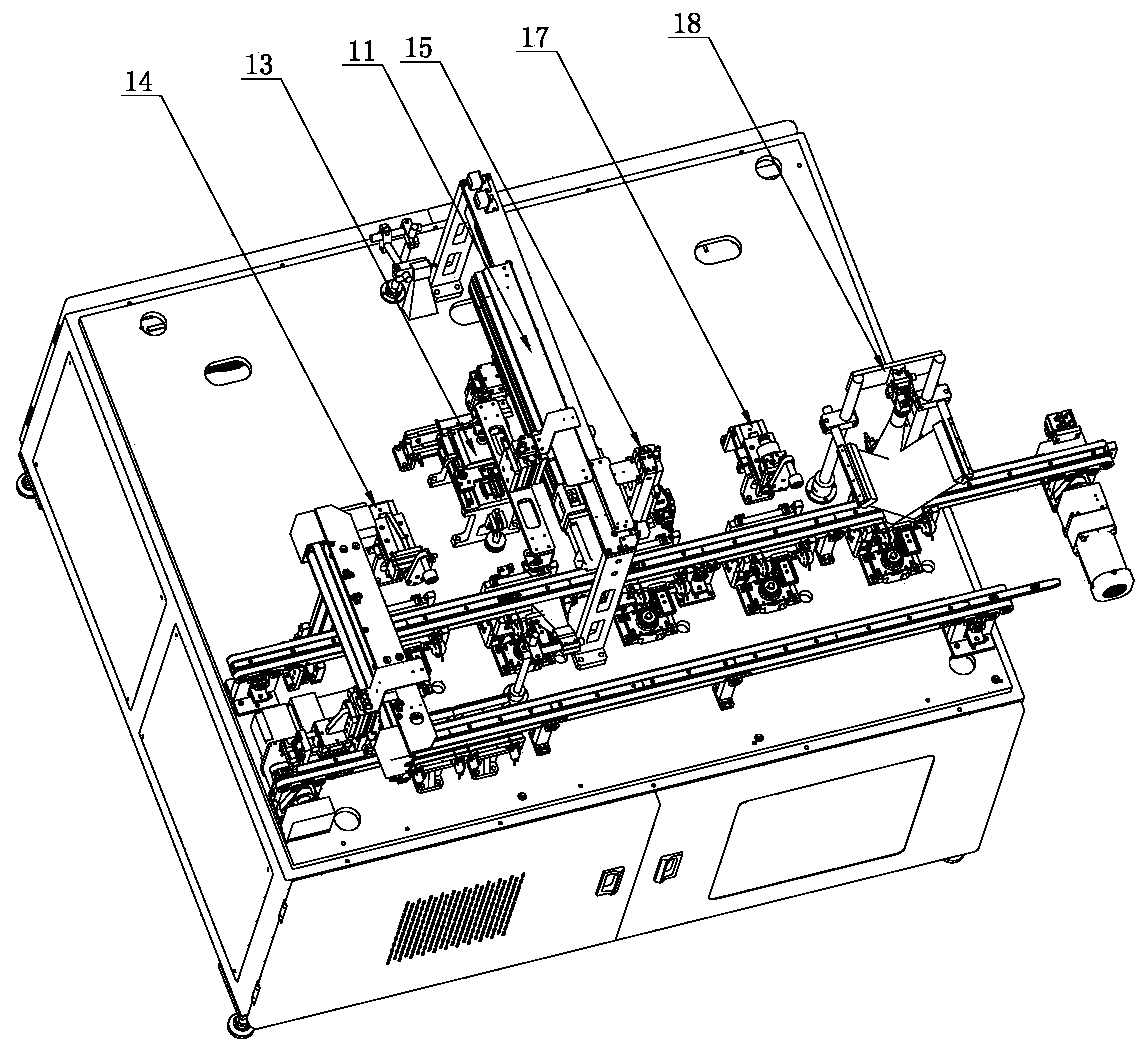

[0042] Such as Figure 1 to Figure 35 As shown, a fully automatic battery gluing production line of the present invention, according to the production process, sequentially includes a battery feeding machine 1, a tab cutting machine 2, a pasting forming glue machine 3, a paste head glue and a liner glue machine 4 , protective plate laser welding machine 5, protective plate bending and shaping machine 6, protective plate plastic shell assembly machine 7, and PI glue and double-sided adhesive glue machine 8, and the empty carrier transportation line 9 and the carrier are respectively connected between each mechanism. Carrier transportation line 010, between the empty carrier transportation line 9 and the carrier transportation line 010, a loading manipulator 011 is arranged. The invention realizes fully automatic operation without manual intervention, reduces producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com