Extrusion head, coating device and coating system

A coating device and extrusion head technology, applied in the extrusion head, lithium battery manufacturing equipment coating machine, coating device and coating system field, can solve the problem of increased equipment maintenance costs, complex control systems, and no energy consumption. Saving and other issues to achieve the effect of saving the time of replacing materials, solving technical bottlenecks, and improving equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

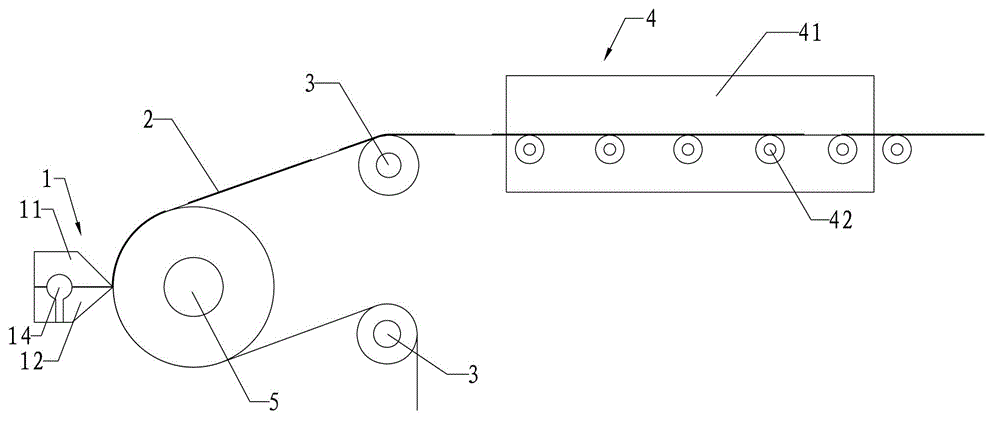

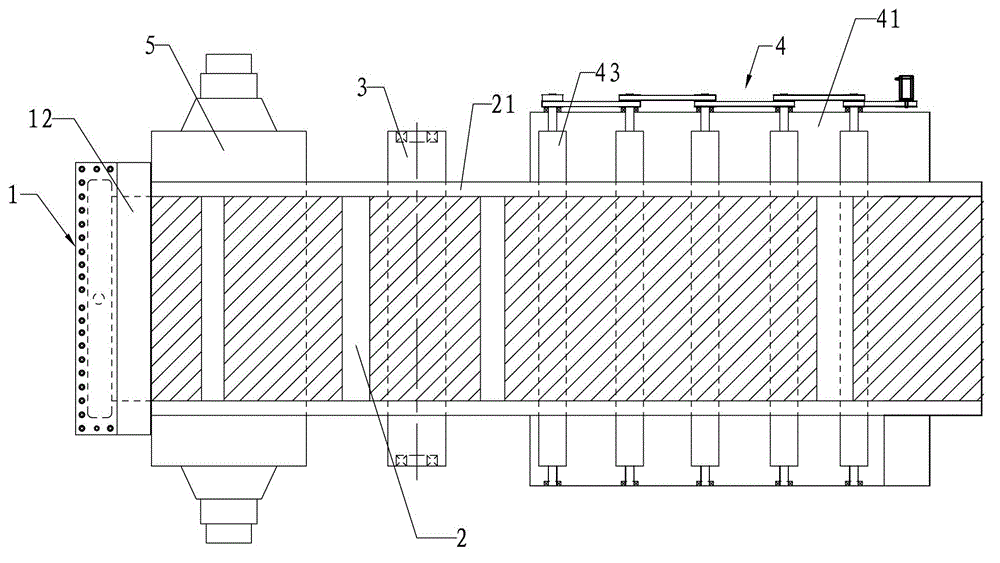

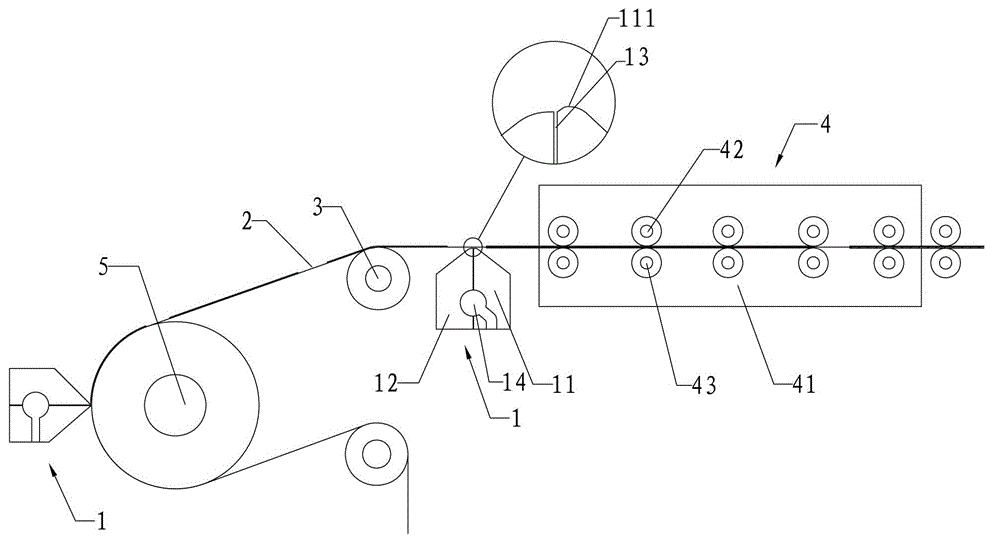

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0024] Refer to attached image 3 , attached Figure 4 , a kind of extruding head 1 that the present invention provides as shown in the drawing, comprises extruding head lower lip 11 and extruding head upper lip 12, is provided with for slurry to pass between extruding head upper lip 12 and extruding head lower lip 11 The extrusion head 1 is also provided with a cavity 14, the cavity 14 leads to the slurry from the outside and communicates with the channel 13, the head of the lower lip 11 of the extrusion head is higher than the head of the upper lip 12 of the extrusion head part, the head of the lower lip 11 of the extrusion head is a rounded corner 111.

[0025] The lip design of the extrusion head 1 is different from the existing extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com