Automatic assembly device for battery pack

An automatic assembly and battery pack technology, which is applied in the direction of manufacturing primary battery equipment, primary batteries, battery assembly machines, etc., can solve the problems of low efficiency of assembly mechanism, incomplete assembly functions, and low level of automation, so as to save labor, Reduce unnecessary losses and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

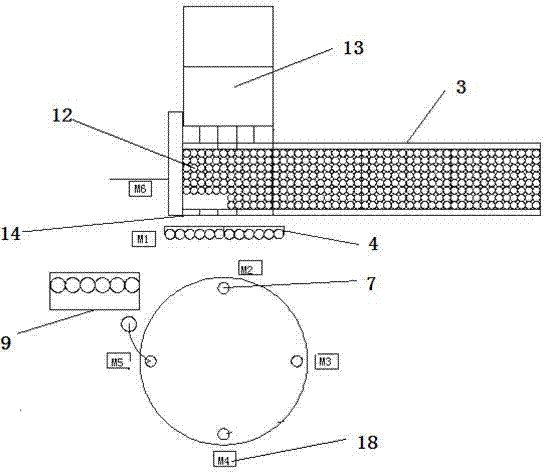

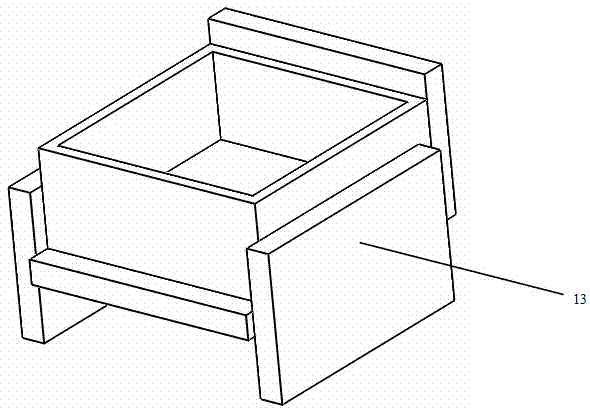

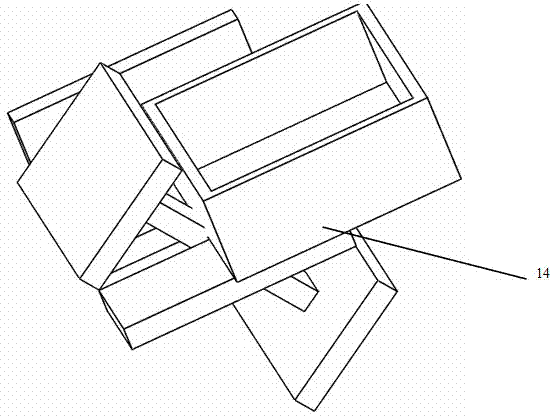

[0021] see figure 1 and figure 2 , a battery pack automatic assembly equipment, including battery feeding mechanism, turntable working mechanism, manipulator mechanism and control mechanism; The conveyor belt driven by the servo motor 18 can automatically push away the battery feeding box turning mechanism 14 of the battery feeding box 13 to be connected with the chute, and the servo motor 18 and the battery feeding box turning mechanism 14 are controlled by the control chip.

[0022] The turntable working mechanism includes a turntable base 11, multiple battery temporary storage concave fixtures 4 (6 sections in this embodiment), a battery box 9, and a set of turntable battery concave fixtures 7 installed on the turntable base 11. The manipulator mechanism includes Multi-cell battery grabbing and placement manipulator 1, single-cell battery loading manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com