Passive spiral homogenization and dust suppression device and technology for grouting materials

A technology of grouting material and dust suppression device, which is applied in the direction of combination device, chemical instrument and method, separation method, etc., to achieve the effect of simplified operation process, less time-consuming and high-precision production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

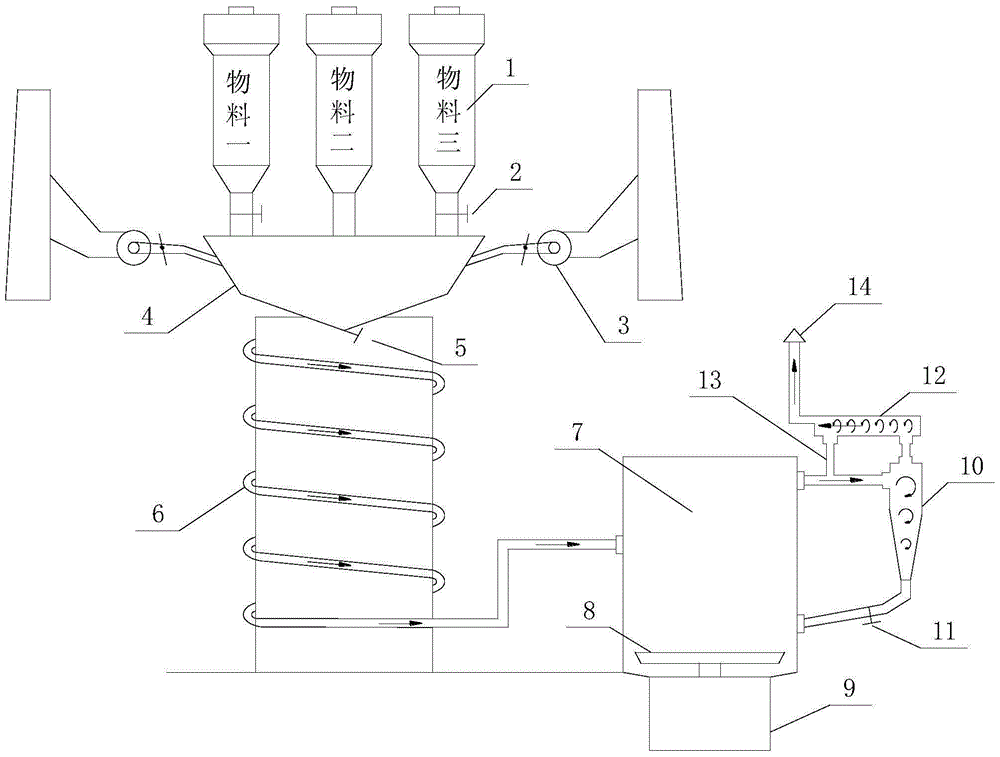

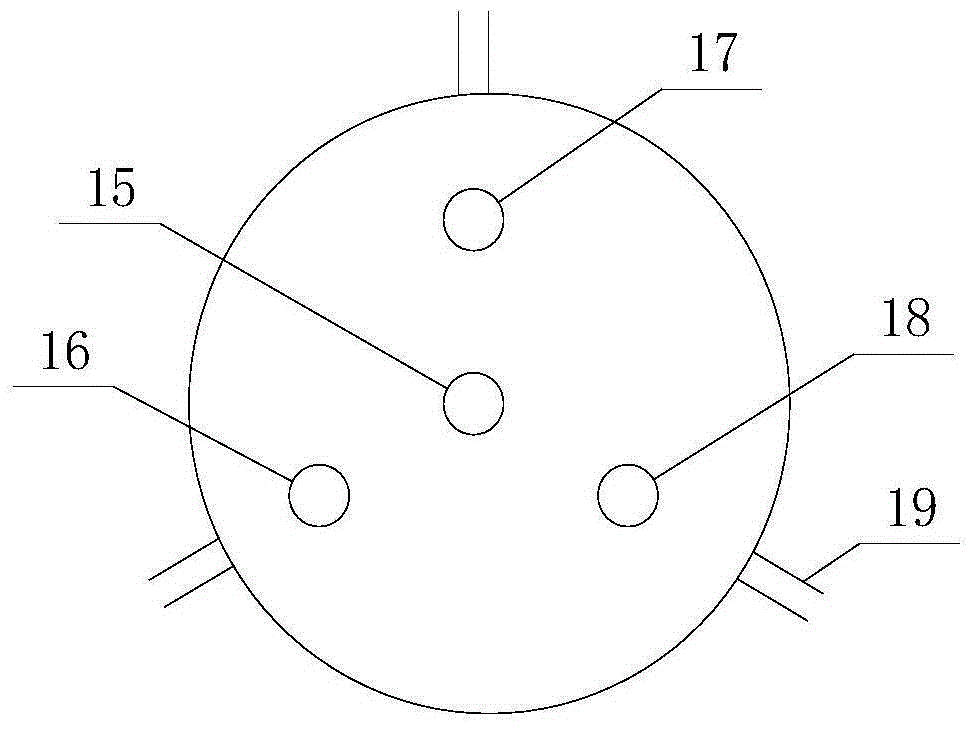

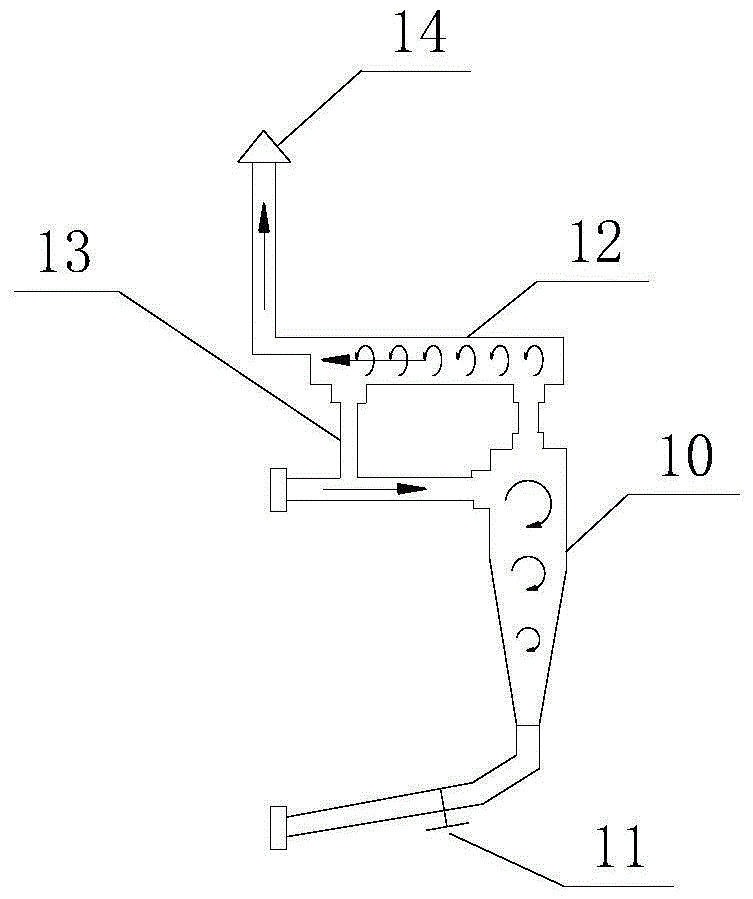

[0036] Such as Figure 1-4 As shown, the novel passive spiral homogenization and dust reduction device for grouting materials includes three grouting material storage tanks 1, the bottom of the grouting material storage tanks 1 communicates with a sealed material transfer container 4, and the material transfer container The interior is connected to the air outlets of 3 fans 3, and the bottom of the material transfer container is connected to the passive spiral homogenizer 6, and the grouting material passes through the passive spiral homogenizer under the action of its own weight and wind force to homogenize the grouting material The outlet of the passive spiral homogenizer is connected to the grouting material stirring tank 7, and the side wall of the grouting material stirring tank 7 is connected with a strong cyclone separator and an electrostatic recirculator, and the stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com