Novel mud solid control system and technology

A phase control and mud technology, applied in solid separation, wellbore/well components, separation methods, etc., can solve the problem of incapacity, equipment purchase cost, electric power consumption and floor space, maintenance system management workload is high, centrifugal Machine can not work and other problems, to achieve the effect of saving floor space, service process and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

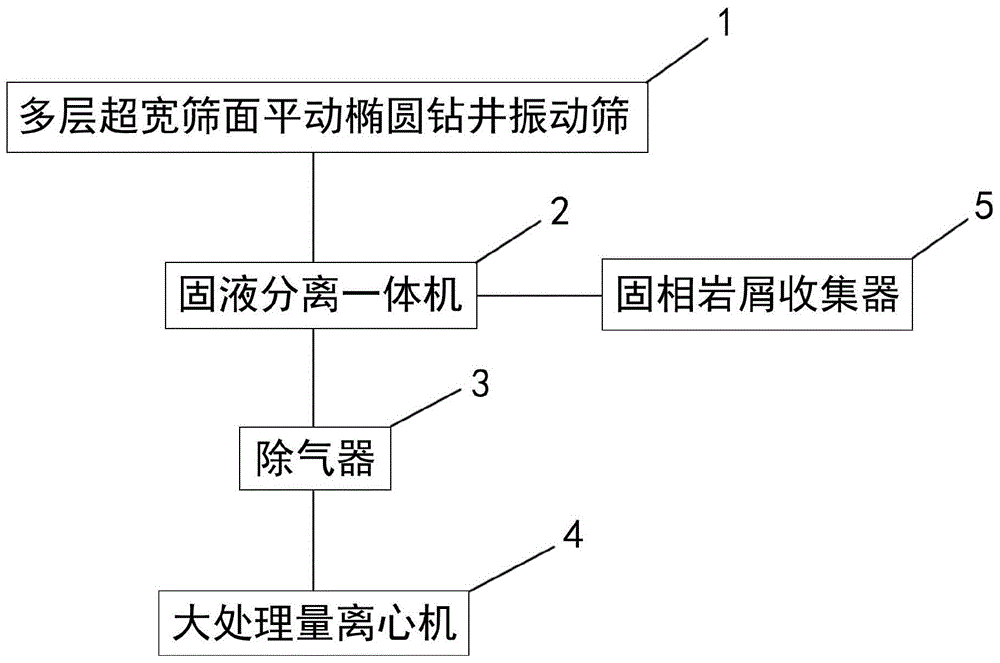

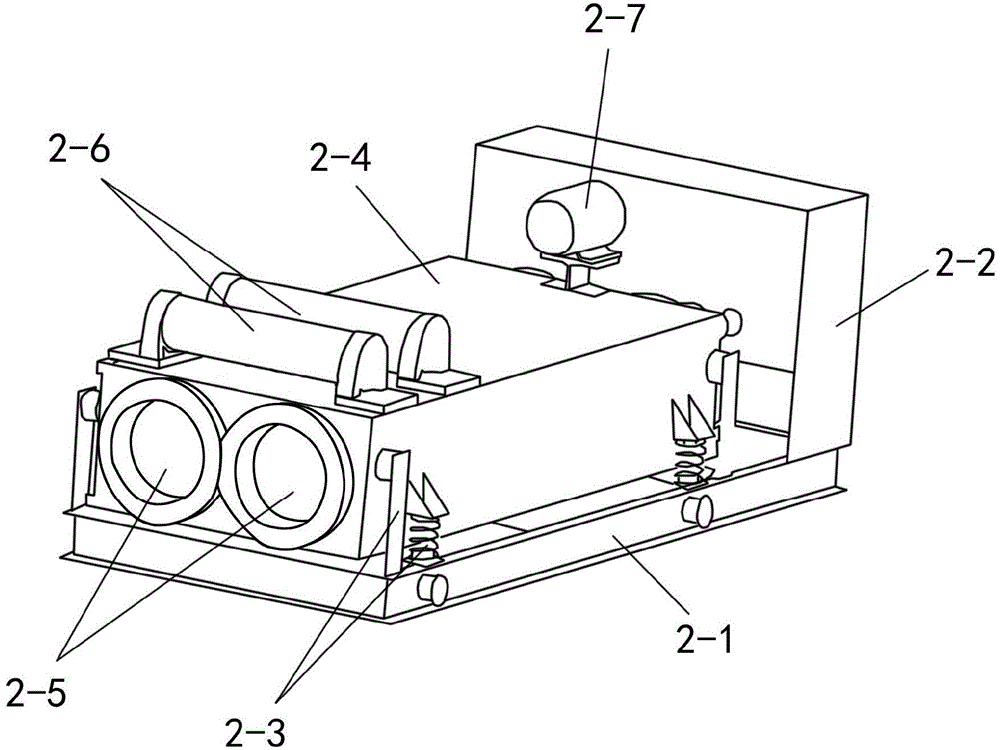

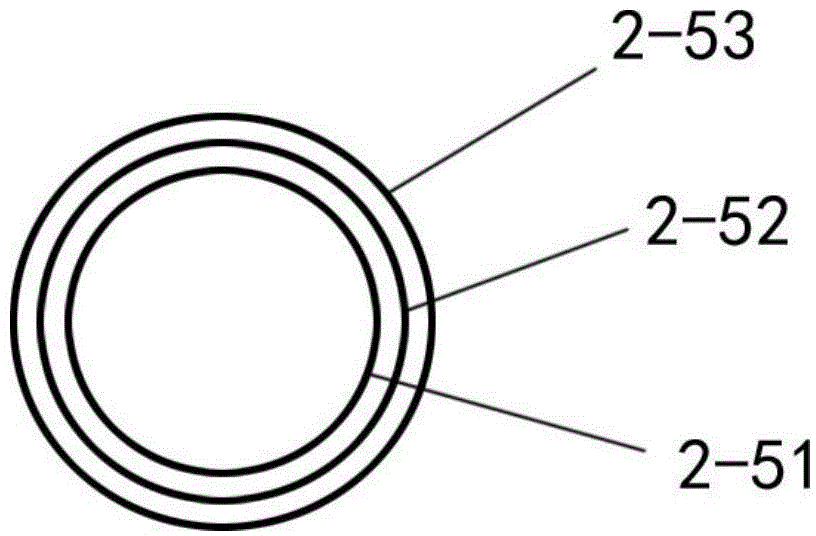

[0019] Such as figure 1 , figure 2 and image 3 As shown, a new mud solid phase control system is characterized in that it includes a multi-layer ultra-wide screen surface translational elliptical drilling shale shaker 1, a solid-liquid separation machine 2, a degasser 3, a large-capacity centrifuge 4 and Solid phase cuttings collector 5; the multi-layer ultra-wide screen surface translational elliptical drilling vibrating screen 1 is provided with 80 mesh, 110 mesh and 140 mesh screens; the solid-liquid separation integrated machine 2 includes a base 2-1, The base 2-1 is provided with a feeding box 2-2 and an oscillating support 2-3, the oscillating support 2-3 is fixed with an oscillating box 2-4, and the oscillating box 2-4 is equipped with a screen drum 2-5, an Vibration motor 2-6 and anti-vibration transmission motor 2-7, anti-vibration transmission motor 2-7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com