Bidirectional drilling construction method of non-demolition water drill for pipe-jacking in solid rock sections

A construction method and non-blasting technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of impenetrable rocky areas, many uncertain factors underground, and large safety hazards, etc., and achieve less demand for electricity and oil, The effect of easy landform recovery and reasonable personnel organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

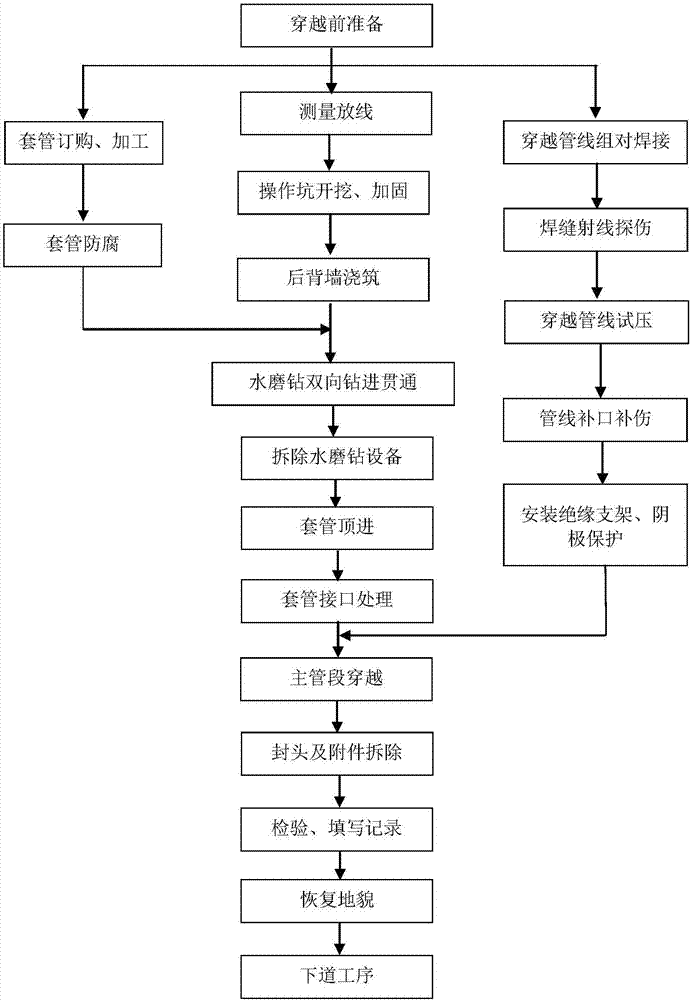

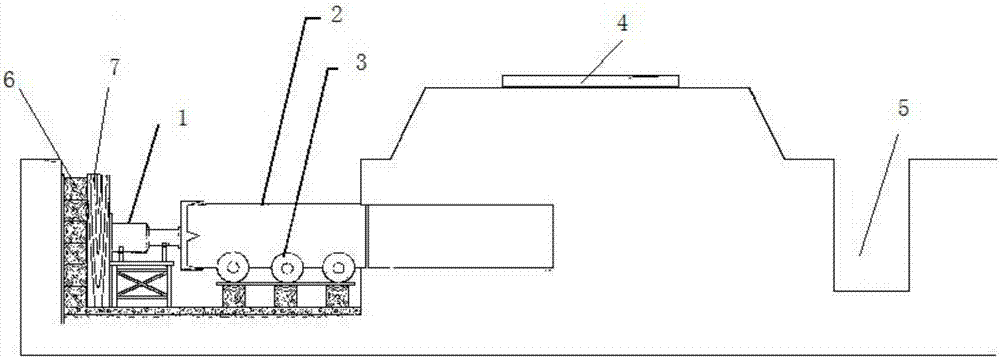

[0031] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] 1. Preparation before crossing

[0033] Verify the crossing angle of the pipe jacking section, the distance between the operation pits, the soil quality and hydrogeological conditions, the structure of the aboveground and underground structures of the pipe jacking section, their foundation method and elevation, and calculate the jacking force required for pipe jacking. According to the topography and landform of the crossing point, determine the discharge point and drainage method of groundwater.

[0034] 2. Measurement and setting out

[0035] Use the total station, theodolite and level to determine the starting and ending points of crossing, the central pile and the sideline pile of the construction operation belt, and sprinkle the center line and boundary line with white ash. Release the centerline of the pipe trench on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com