Process for liquid-state carbon dioxide cracking rocks

A technology of liquid carbon dioxide and process method, applied in the directions of weapon accessories, blasting cylinders, blasting, etc., can solve the problems such as the safety of nearby buildings that affect the normal life of the surrounding people, difficult to handle, and increase the difficulty of construction, so as to facilitate the work of the crusher and reduce the construction cost. , the effect of promoting expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A kind of technological method of cracking rock with liquid carbon dioxide, comprises the following steps:

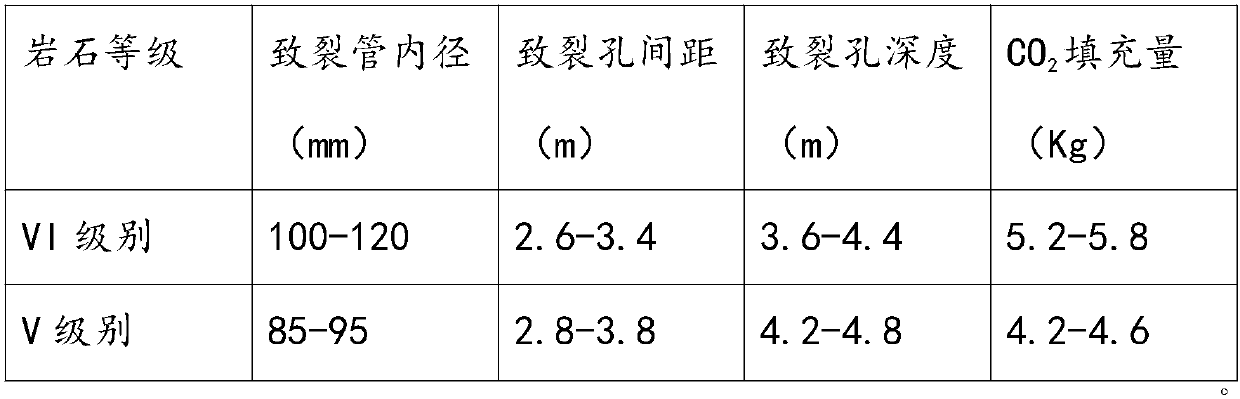

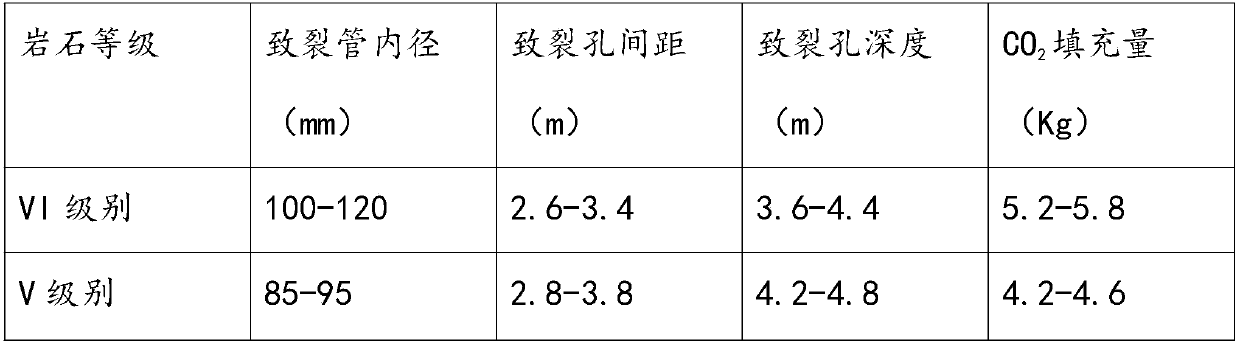

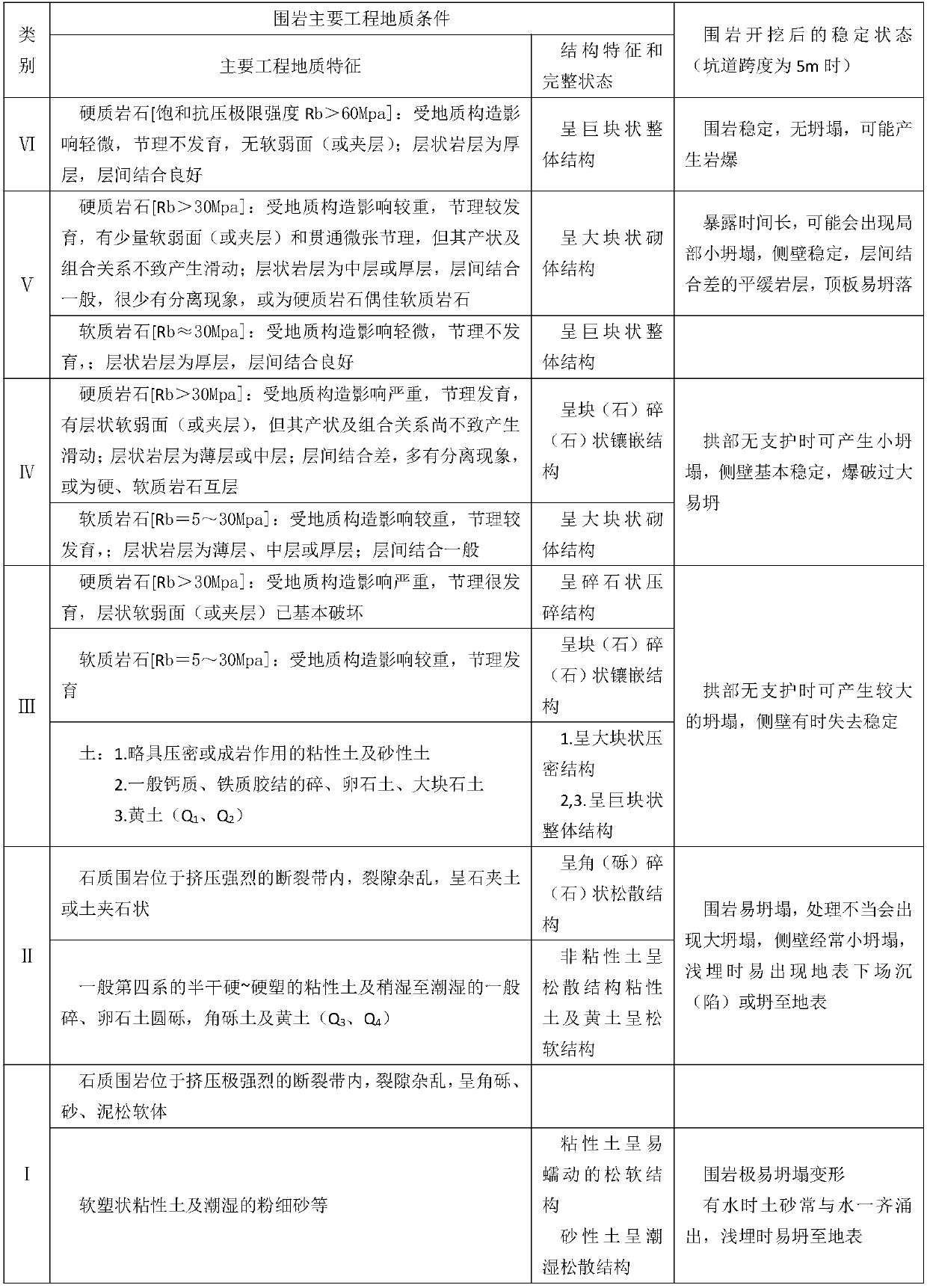

[0041] S1: Detect the rock grade of the blasting object. For the rocks that need to be cracked, generally there are only grade V and grade VI, and this embodiment is grade V;

[0042] S2: Since the rock grade is V grade, the inner diameter of the fracturing tube is 85mm, the distance between the fracturing holes is 3.8m, and the depth of the fracturing holes is 4.2m. 2 The filling amount is 4.2Kg, and the length of the cracking tube is 0.96m;

[0043] S3: Open the air surface required for blasting, then install the dust collector on the drilling rig, and use the down-the-hole drill to open the fracturing hole. Auxiliary fracturing holes are added on both sides of the fracturing hole, and the depth of the auxiliary fracturing hole is 4m;

[0044] S4: Check and clean the drilled fracturing hole, the impurities in the hole have been cleaned up, the m...

Embodiment 2

[0048] Embodiment 2: A kind of technological method of cracking rock with liquid carbon dioxide, comprises the following steps:

[0049] S1: Detect the rock grade of the blasting object. For the rocks that need to be cracked, generally there are only grade V and grade VI, and this embodiment is grade VI;

[0050] S2: Since the rock grade is VI, the inner diameter of the fracturing tube is 120mm, the distance between the fracturing holes is 3.4m, and the depth of the fracturing holes is 4.4m. 2The filling amount is 5.8Kg, and the length of the cracking tube is 1.6m;

[0051] S3: Open the air surface required for blasting, then install the dust collector on the drilling rig, and use the down-the-hole drill to open the fracturing hole. Auxiliary fracturing holes are added on both sides of the fracturing hole, and the depth of the auxiliary fracturing hole is 5m;

[0052] S4: Check and clean the drilled fracturing hole, the impurities in the hole have been cleaned up, the measur...

Embodiment 3

[0056] Embodiment 3: a kind of technological method of cracking rock with liquid carbon dioxide, comprises the following steps:

[0057] S1: Detect the rock grade of the blasting object. For the rocks that need to be cracked, generally there are only grade V and grade VI, and this embodiment is grade VI;

[0058] S2: Since the rock grade is VI, the inner diameter of the fracturing tube is 100mm, the distance between the fracturing holes is 2.6m, and the depth of the fracturing holes is 3.6m. 2 The filling amount is 5.2Kg, and the length of the cracking tube is 1.1m;

[0059] S3: Open the air surface required for blasting, then install the dust collector on the drilling rig, and use the down-the-hole drill to open the fracturing hole. Auxiliary fracturing holes are added on both sides of the fracturing hole, and the depth of the fracturing hole is 4m;

[0060] S4: Check and clean the drilled fracturing hole, the impurities in the hole have been cleaned up, the measured parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com