Expansion grouting anchor rod

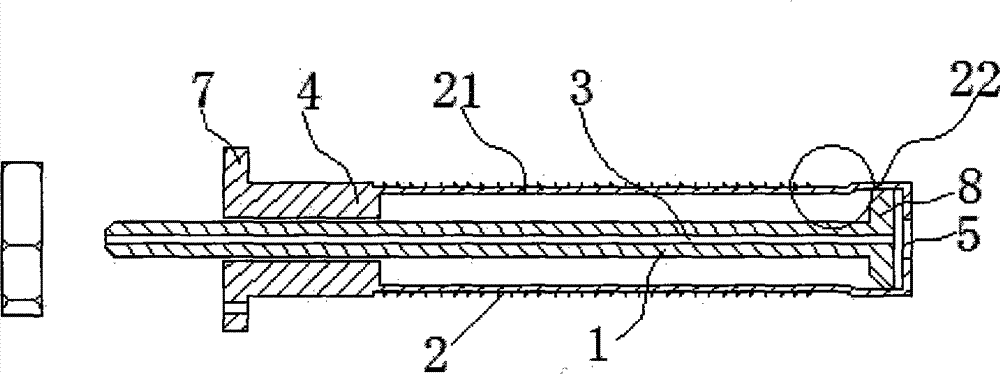

A bolt and grouting technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of limited screw length, vulnerability to impact, and small anchoring range of expansion bolts, so as to increase the degree of anchoring, Combining firmness and improving the effect of anchorage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

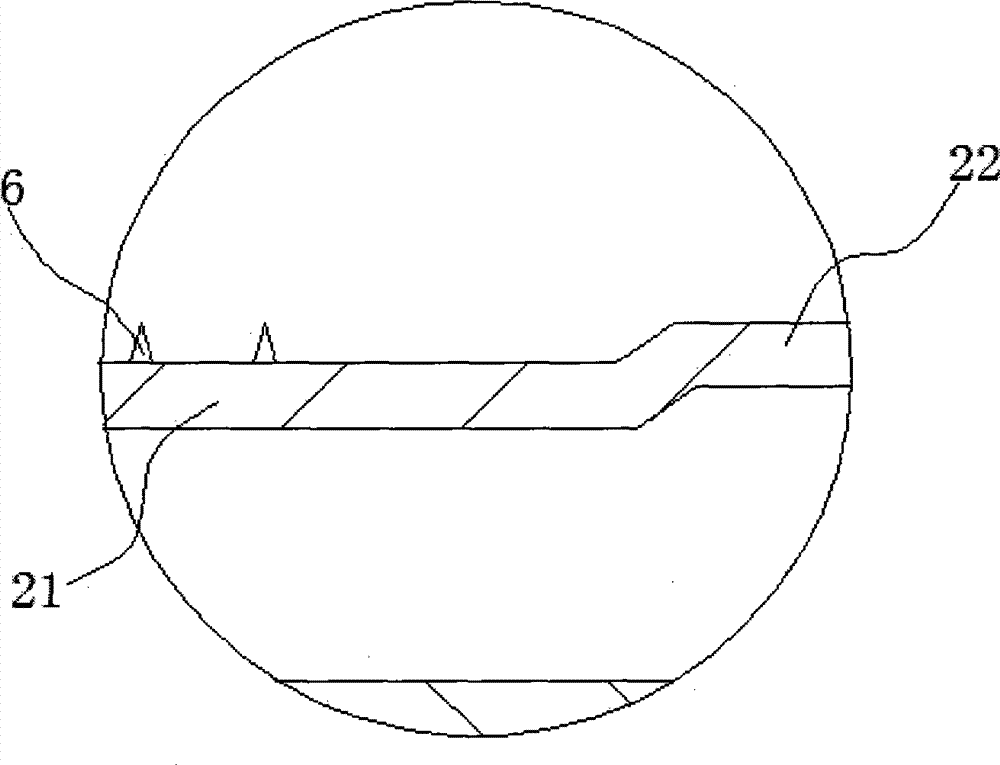

[0016] When drilling and anchoring a hard coal seam, first open a hole matching the gap of the sleeve 2 at a predetermined position, insert the screw into the hole, and tighten the nut on the anchor rod assembly 1 to make The expansion head 8 moves axially outwards. When the expansion head passes through the expansion tube 21, the expansion tube 21 is expanded, and the upper corner of the ring 6 provided on the expansion tube 21 can be further embedded in the hole wall, thereby To achieve the purpose of tightly connecting the screw and the hole.

Embodiment 2

[0018] When drilling and anchoring a relatively soft coal seam, first open a hole matching the gap of the sleeve 2 at a predetermined position, insert the screw into the hole, and tighten the nut on the anchor rod assembly 1 to expand The head 8 moves axially outward. When the expansion head passes through the expansion tube 21, the expansion tube 21 is stretched. Because the hole wall is loose and there are a lot of cracks at this time, the ring teeth 6 cannot fit well with the hole wall. At this time, the grouting port of the grouting machine is docked with the screw in the bolt assembly 1, and it is preferable to adopt quick-setting and early-strength grouting. The quick-setting and early-strength grouting is injected into the expansion pipe 21 through the grouting pipe 3 on the screw. The quick-setting and early-strength grouting injected into the expansion pipe 21 further penetrates into the gap of the hole wall through the cracks on the expansion pipe 21 and the grouting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com