High-efficiency mining method of dragline saw-tooth type working bench

A mining method, zigzag technology, which is applied in the field of high-efficiency mining of dragline zigzag working flat disks, can solve the problem of reducing the effective stacking efficiency of draglines, increasing the amount of secondary stacking in the stripping link of dragline scraping, and increasing the Single-bucket excavators, flat plate trucks to expand the workload and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

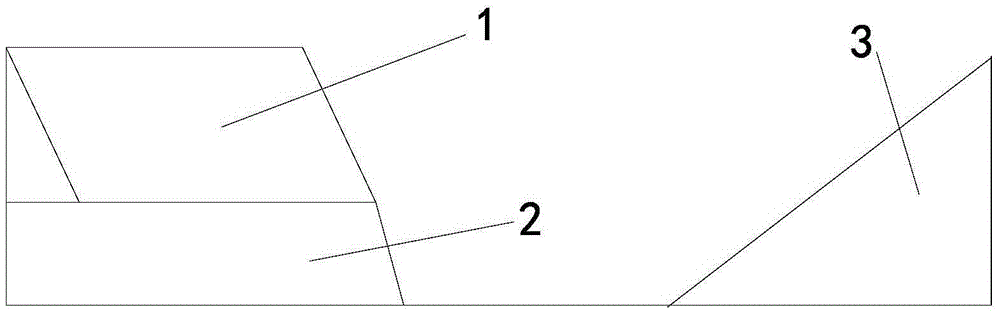

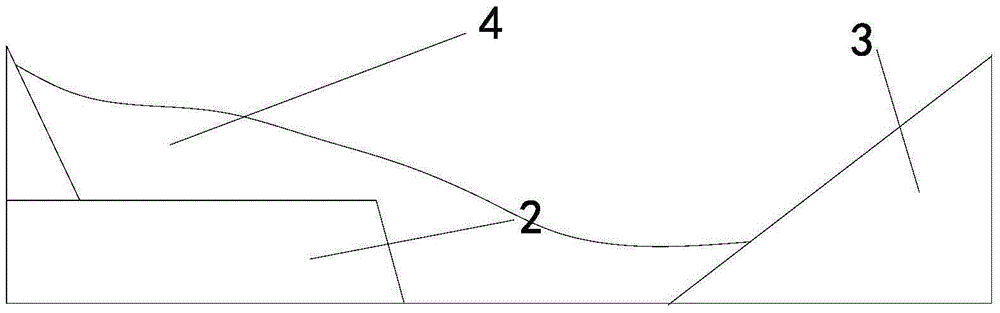

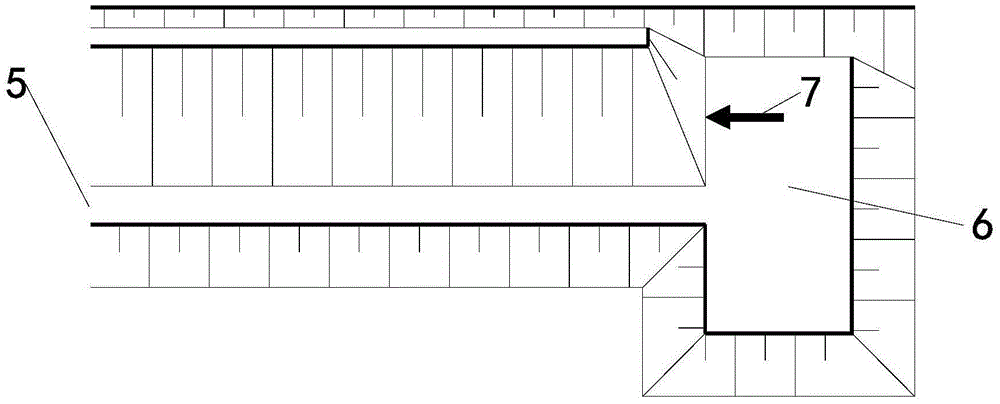

[0039] The following is a detailed description of a dragline sawtooth-shaped working flat disk efficient mining method according to an embodiment of the present invention in conjunction with the accompanying drawings.

[0040] It should be clear that the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0041] see Figure 1 to Figure 6 , an embodiment of a method for efficient mining of a dragline zigzag working flat disk according to the present invention, comprising:

[0042] Step 1. Throwing and blasting the solid rock steps on the upper part of the coal seam to form a blast pile.

[0043] In this step, blastholes are drilled in advance on the solid high steps above the coal seam by using a perforating drilling rig, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com