High-ductility dynamic coupling mining anchor cable device

A dynamic coupling and high elongation technology, applied in mining equipment, bolt installation, earthwork drilling and mining, etc., can solve the problems of large extension length, loss of joint support, etc., to increase the range of deformation displacement, improve service life, The effect of increasing the effective usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

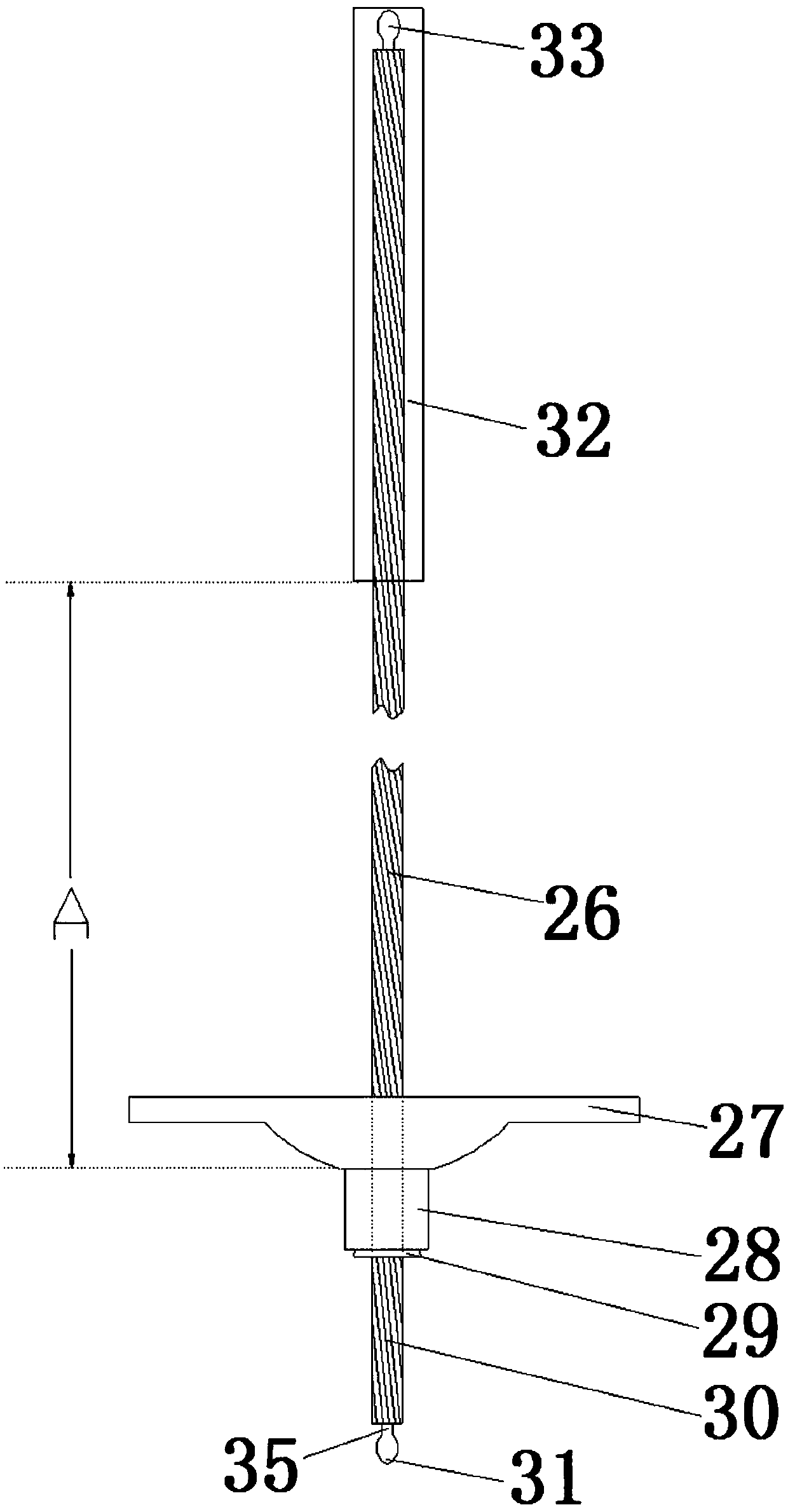

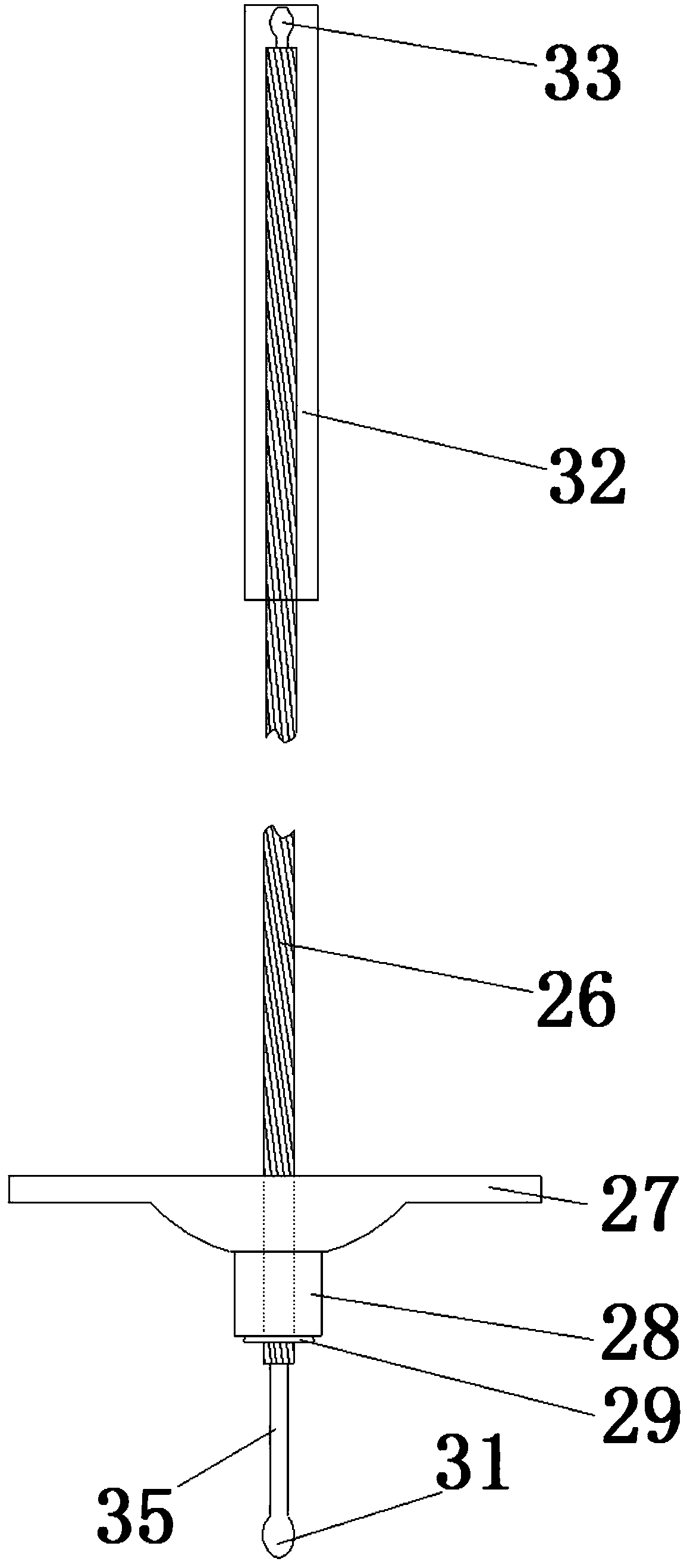

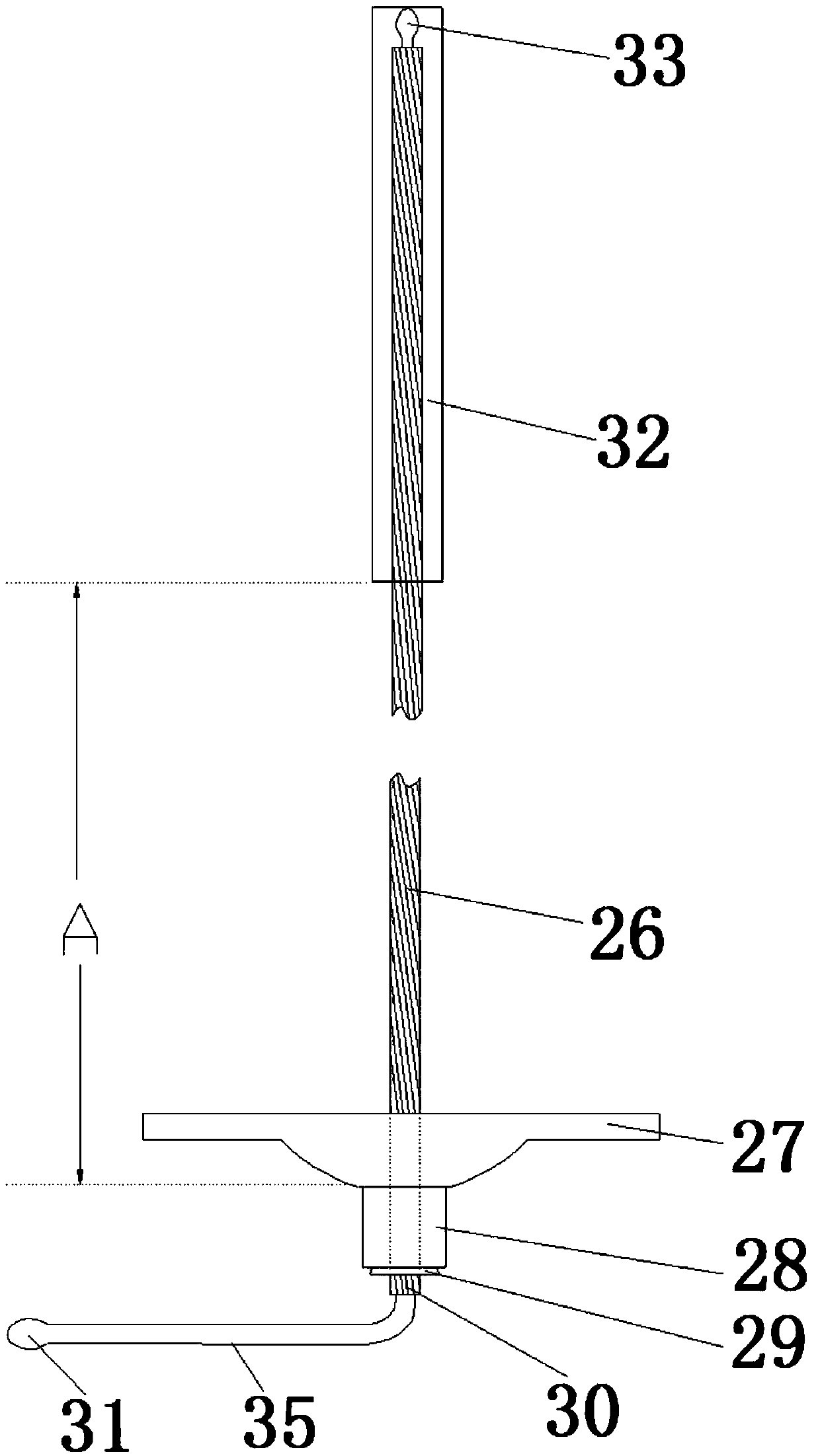

[0023] Such as Figure 1-6 As shown, the high-elongation dynamic coupling mine anchor cable device includes an anchor cable steel strand, an anchor cable disc 27 arranged on the anchor cable steel strand in turn, an anchor ring 28 connected with the anchor cable disc 27, and an anchor ring 28 connected with the anchor cable strand. The rigging clip 29 connected by the ring 28; the anchor cable steel strand includes the anchor cable inner section 26 and the anchor outside the rigging clip 29 which are arranged in the anchor cable plate 27 and anchored in the stable rock around the roadway Cable exposed end 30; the end of the inner section 26 of the anchor cable is provided with an anchor cable anchor end core wire welding spot 33; the end of the anchor cable exposed end 30 is provided with an anchor cable exposed end core wire welding spot 31 ;

[0024] Such as Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com