Adc12 die-casting aluminum alloy black chromium-free conversion film treatment agent and surface treatment method of adc12 die-casting aluminum alloy

A technology of ADC12 and cast aluminum alloy, which is applied in the direction of metal material coating process, etc., can solve the problems of poor environmental protection, pollution, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A surface treatment method for ADC12 die-casting aluminum alloy, which comprises the steps of:

[0065] (1) Put the ADC12 die-casting aluminum alloy into the degreasing agent for degreasing and degreasing treatment. The degreasing agent includes the following concentrations of components: sodium pyrophosphate 10 g / L, sodium tripolyphosphate 20 g / L, sodium metasilicate 5 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.25 g / L, K12 anionic active agent 1 g / L. The temperature of the degreasing treatment is 60 degrees centigrade, and the treatment time is 6 minutes. After washing with water, put it into the whitening solution below for whitening treatment.

[0066] (2) Putting the ADC12 die-casting aluminum alloy after the degreasing and degreasing treatment into a whitening agent for whitening treatment. The whitening agent is A434 environmental protection whitening agent, which is produced by Dongming Chemical Industry in Boluo County. After washing with water, put it ...

Embodiment 2

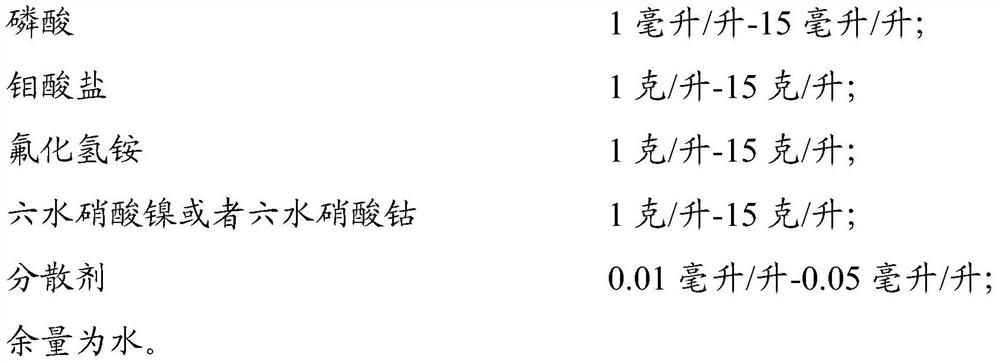

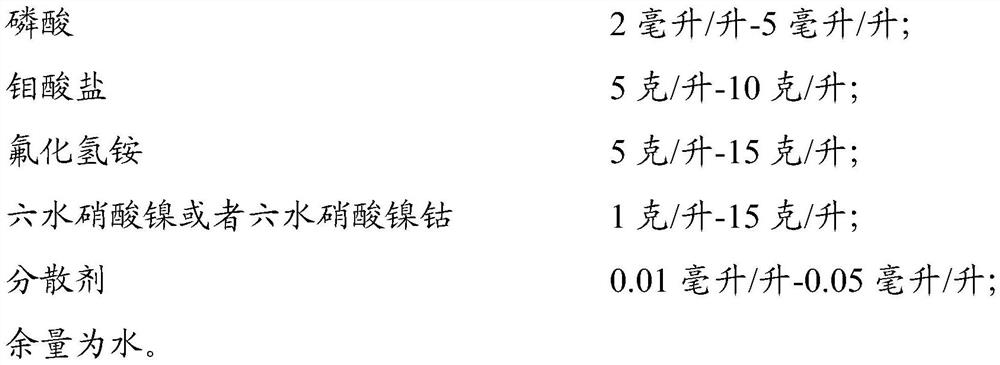

[0071] Different from Example 1, the ADC12 die-casting aluminum alloy black chromium-free conversion film treatment agent comprises the components of the following concentrations: 5 milliliters / liter of 85% phosphoric acid; 5 grams / liter of ammonium molybdate (sodium); 15 grams of ammonium bifluoride / liter; nickel nitrate hexahydrate (cobalt) 3 g / liter; dispersant 0.01 ~ 0.05 ml / liter, the balance is water.

Embodiment 3

[0073] Different from Example 1, the ADC12 die-casting aluminum alloy black chrome-free conversion coating treatment agent comprises the components of the following concentrations: 2 ml / liter of 85% phosphoric acid; 10 grams / liter of ammonium molybdate (sodium); 5 grams of ammonium bifluoride / liter; nickel (cobalt) nitrate hexahydrate 5 g / liter; dispersant 0.01 ~ 0.05 ml / liter, the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com