Efficient anticorrosion zinc-type phosphating solution and preparation method thereof

A zinc-based phosphating solution, high-efficiency technology, applied in phosphating, etc., can solve the problems of secondary pollution, inability to form a film, slow phosphate film speed, etc., to achieve improved corrosion resistance, improved anti-corrosion effect, and good dispersion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

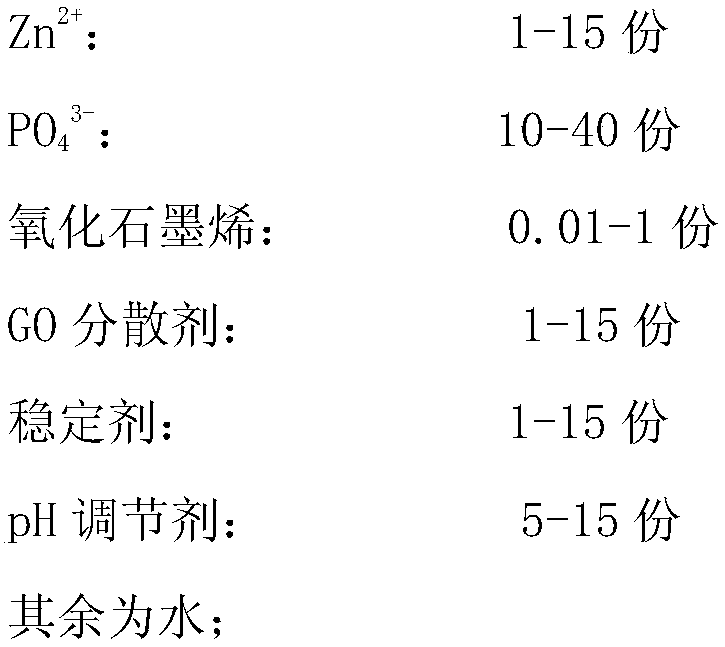

[0030] A high-efficiency anti-corrosion zinc-based phosphating solution, whose raw material formula consists of:

[0031]

[0032] A high-efficiency anti-corrosion zinc-based phosphating solution is prepared through the following steps:

[0033] Get graphene oxide (GO) 1g in 1L water, carry out ultrasonic dispersion, after dispersing evenly, add zinc oxide 5g, sodium phosphate 10g, fatty acid polyethylene glycol ester 1g, and continue ultrasonic dispersion to dissolve completely; The pH is about 4, stir evenly and store at room temperature to obtain a high-efficiency anti-corrosion zinc-based phosphating solution.

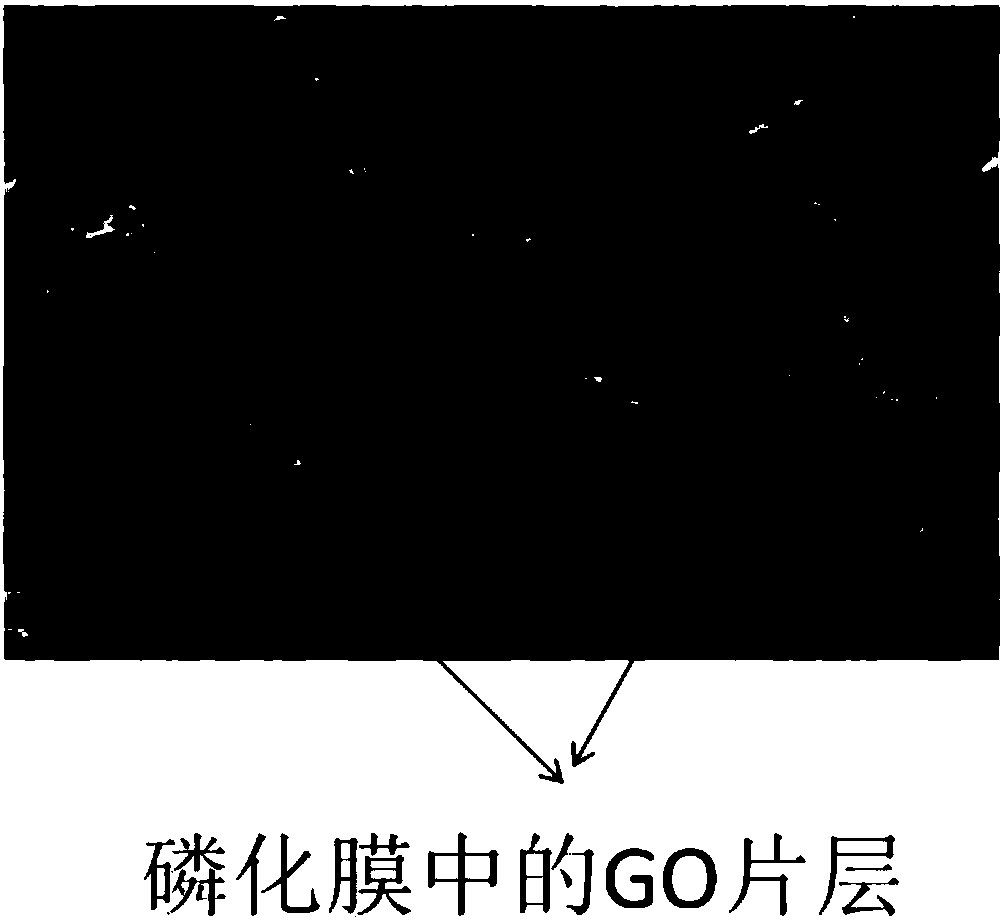

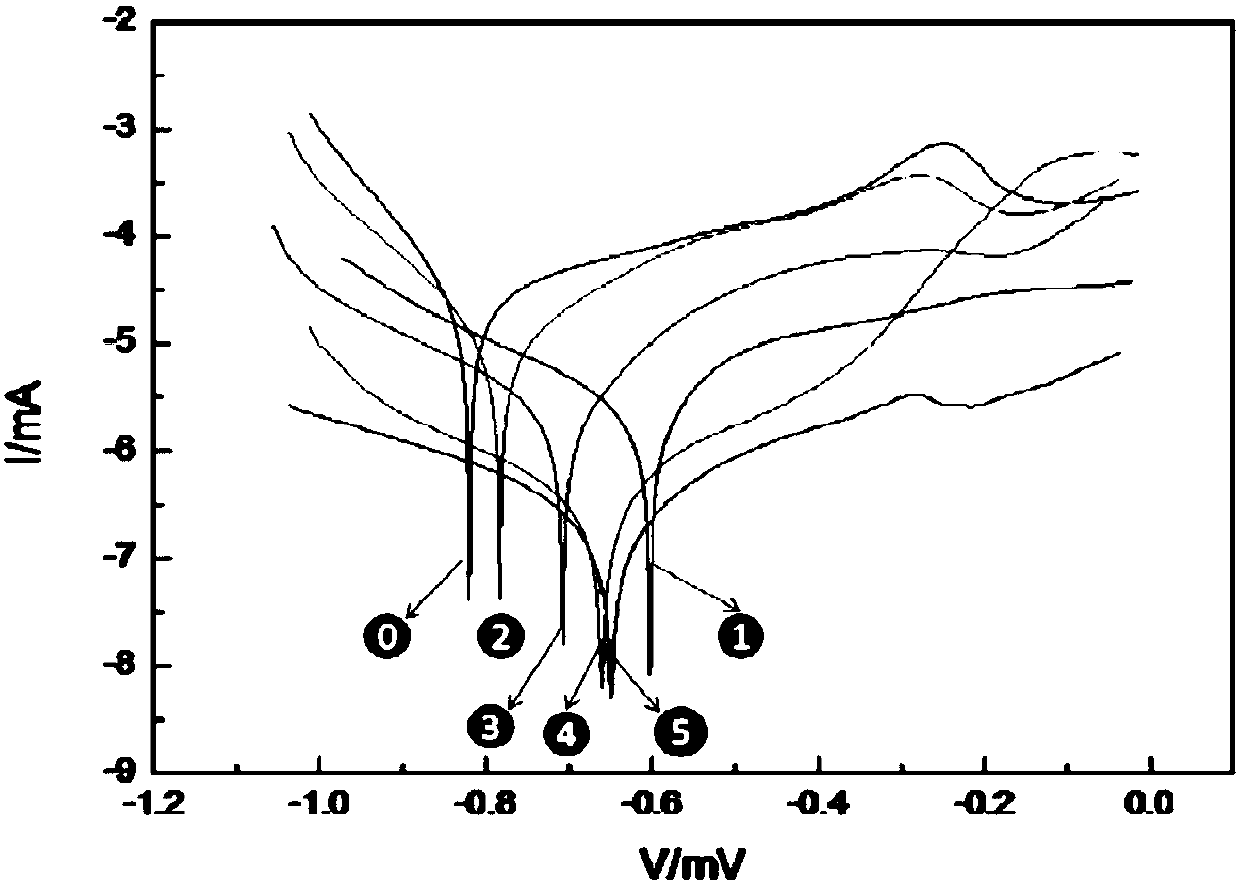

[0034] Put the prepared high-efficiency anti-corrosion zinc-based phosphating solution into the three-electrode phosphating pool, and the metal workpiece is used as the cathode for electrochemical phosphating. The phosphating time is 1 minute. During the phosphating process, there are a large number of negative electrons on the surface of the workpiece. Zn in p...

Embodiment 2

[0043] A high-efficiency anti-corrosion zinc-based phosphating solution, whose raw material formula consists of:

[0044]

[0045]

[0046] A high-efficiency anti-corrosion zinc-based phosphating solution is prepared through the following steps:

[0047] Take graphene oxide (GO): 0.01g in 1L water, carry out ultrasonic dispersion, after the dispersion is uniform, add 20g of zinc chloride, 40g of sodium phosphate, 15g of triethylhexyl phosphoric acid, and continue ultrasonic dispersion until completely dissolved; adjust with ammonia water The pH of the solution is about 5. Stir it evenly enough to store it at room temperature, and you can get this new type of high-efficiency anti-corrosion zinc-based phosphating solution.

[0048] Put the prepared new high-efficiency anti-corrosion zinc-based phosphating solution into the three-electrode phosphating pool, and the metal workpiece is used as the cathode for electrochemical phosphating. The phosphating time is 1 minute. Duri...

Embodiment 3

[0051] A high-efficiency anti-corrosion zinc-based phosphating solution, whose raw material formula consists of:

[0052]

[0053] A high-efficiency anti-corrosion zinc-based phosphating solution is prepared through the following steps:

[0054] Take graphene oxide (GO): 0.03g in 1L water, carry out ultrasonic dispersion, after the dispersion is uniform, add 10g of zinc sulfide, 26g of potassium hydrogen phosphate, 8g of sodium lauryl sulfate, and continue to carry out ultrasonic dispersion until completely dissolved; Use sodium hydrogen to adjust the pH of the solution to about 4.5, stir it evenly and store it at room temperature to obtain this new type of high-efficiency anti-corrosion zinc-based phosphating solution.

[0055] Put the prepared new high-efficiency anti-corrosion zinc-based phosphating solution into the three-electrode phosphating pool, and the metal workpiece is used as the cathode for electrochemical phosphating. The phosphating time is 1 minute. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com