A kind of white metal continuous chlorine gas leaching method

A white alloy and leaching technology, applied in the direction of improving process efficiency, can solve the problems of low leaching rate, high cobalt and copper content in leaching slag, slow reaction speed, etc., and achieve the effect of high reactivity and improved economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

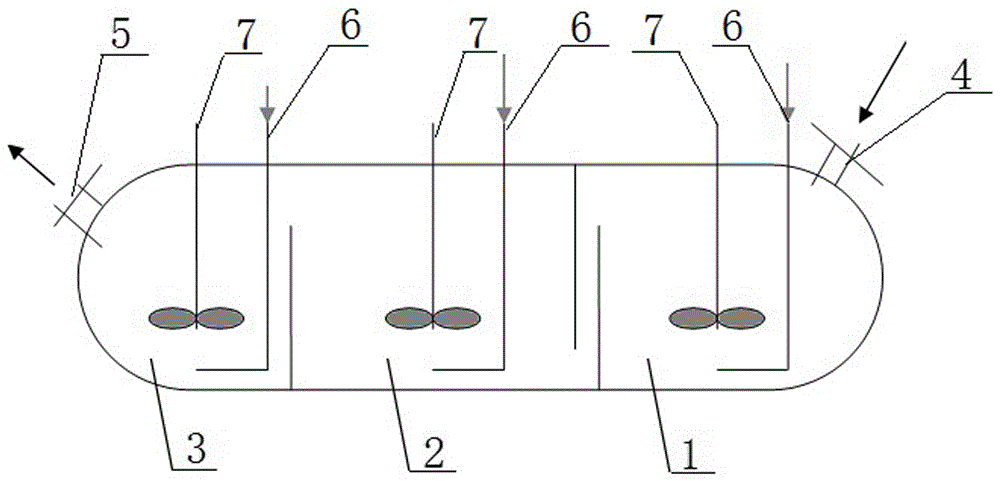

Image

Examples

Embodiment 1

[0024] The white metal is crushed and sieved to -80 mesh, and the sieved white metal material is put into a three-compartment reactor at a rate of 400kg / h. The concentration is 60g / L hydrochloric acid solution, the liquid-solid ratio is 5:1, the temperature of the leaching process is 85°C, the potential of the 1# compartment of the leaching kettle is 497mV, the potential of the 2# compartment is 500mV, the potential of the 3# compartment is 655mV, and the leaching time is 8.2h. Slurry: The slurry obtained after leaching is continuously discharged to the leaching intermediate tank, and the leachate and filter residue are obtained by filtering with a plate and frame filter press; the filter residue is discarded after washing and filtering, and the filter residue cleaning solution is recovered.

Embodiment 2

[0026] The white metal is crushed and sieved to -100 mesh, and the sieved white metal material is put into a three-compartment reactor at a rate of 400kg / h. The concentration is 70 / L hydrochloric acid solution, the liquid-solid ratio is 5:1, the temperature of the leaching process is 104°C, the potential of the 1# compartment of the leaching kettle is 480mV, the potential of the 2# compartment is 520mV, the potential of the 3# compartment is 680mV, and the leaching time is 8h. The slurry obtained after leaching is continuously discharged to the leaching intermediate tank, and the leachate and filter residue are obtained by filtering with a plate and frame filter press; the filter residue is discarded after washing and filtering, and the filter residue cleaning solution is recovered.

Embodiment 3

[0028] The white metal is crushed and sieved to -80 mesh, and the sieved white metal material is put into a three-compartment reactor at a rate of 400kg / h. Concentration 80g / L hydrochloric acid solution, liquid-solid ratio 5:1, leaching process temperature 110°C, leaching kettle 1# compartment potential 495mV, 2# compartment potential 550mV, 3# compartment potential 685mV, leaching time 7.5h, to obtain slurry The slurry obtained after leaching is continuously discharged to the leaching intermediate tank, and the leachate and filter residue are obtained by filtering with a plate and frame filter press; the filter residue is discarded after washing and filtering, and the filter residue cleaning solution is recovered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com