Low-temperature glaze with silver white metal luster and preparation method thereof

A metallic luster and silver-white technology, applied in the field of metallic luster glaze, can solve the problems of difficult operation and high cost, and achieve the effect of simple use method, low glaze cost and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

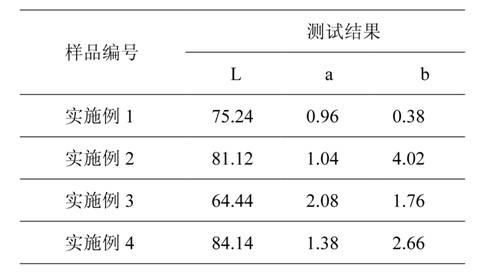

Examples

preparation example Construction

[0022] The preparation method of the above-mentioned low-temperature silver-white metallic luster glaze comprises the following steps:

[0023] 1) Sodium ferric pyrophosphate and ferric orthophosphate are pre-calcined separately or mixed;

[0024] 2) Crush the pre-fired sodium ferric pyrophosphate, ferric orthophosphate and ceramic-based glaze, and mix them evenly;

[0025] 3) Add binder and debonding agent, stir and mix evenly to obtain a mixture;

[0026] 4) Add water to the mixture, and ball mill it into a slurry to obtain a low-temperature silver-white metallic luster glaze.

[0027] The calcining temperature of sodium ferric pyrophosphate and ferric orthophosphate is 500-1000°C.

[0028] Preferably, the amount of the binder added is 0.3-0.5% of the total mass of sodium ferric pyrophosphate, iron orthophosphate and ceramic-based glaze, and the binder is preferably sodium carboxymethylcellulose. Of course, those skilled in the art can also choose other adhesives as neede...

Embodiment 1

[0033] 1) 15 parts of sodium ferric pyrophosphate and 7 parts of iron orthophosphate were pre-calcined at 500 ° C, and then the pre-fired materials were pulverized;

[0034] 2) Mix crushed sodium ferric pyrophosphate, ferric orthophosphate and 28 parts of crushed ceramic-based glaze, add 0.4% of CMC and 0.2% of tripolyphosphoric acid to the total mass of sodium ferric pyrophosphate, ferric orthophosphate and ceramic-based glaze Sodium, wherein the composition of the ceramic base glaze is 20 parts of albite, 2 parts of quartz, 2 parts of limestone, and 4 parts of kaolin;

[0035] 3) According to the material: water = 100:80, add water, ball mill, control the fineness of the slurry to 325 mesh, the sieve residue is 1% smaller, adjust the specific gravity of the slurry to about 1.4, homogenize into a glaze slurry in 24 hours, and obtain a low-temperature silvery white Metallic glaze.

Embodiment 2

[0037] 1) 20 parts of sodium ferric pyrophosphate and 9 parts of ferric orthophosphate were pre-calcined at 700 ° C, and then the pre-fired materials were pulverized;

[0038] 2) Mix the crushed sodium ferric pyrophosphate, ferric orthophosphate and 63 parts of crushed ceramic-based glaze, add 0.5% CMC and 0.3% tripolyphosphoric acid to the total mass of sodium ferric pyrophosphate, ferric orthophosphate and ceramic-based glaze Sodium, wherein the composition of the ceramic base glaze is 50 parts of albite, 2 parts of quartz, 1 part of limestone, and 10 parts of kaolin;

[0039] 3) According to the material: water = 110:90, add water, ball mill, control the fineness of the slurry to 325 mesh, the sieve residue is 1% smaller, adjust the specific gravity of the slurry to about 1.4, homogenize into a glaze slurry in 24 hours, and obtain a low-temperature silvery white Metallic glaze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com