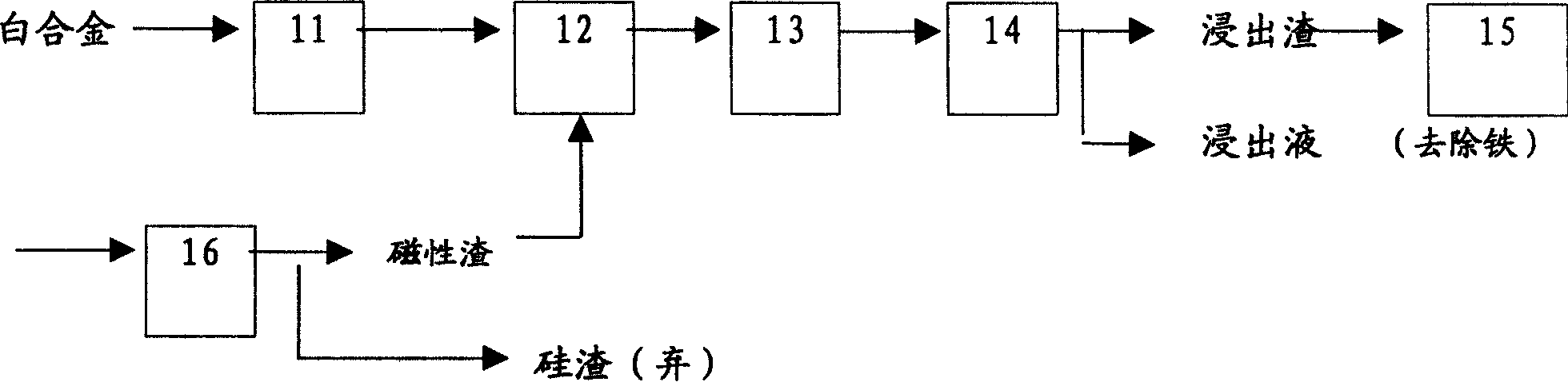

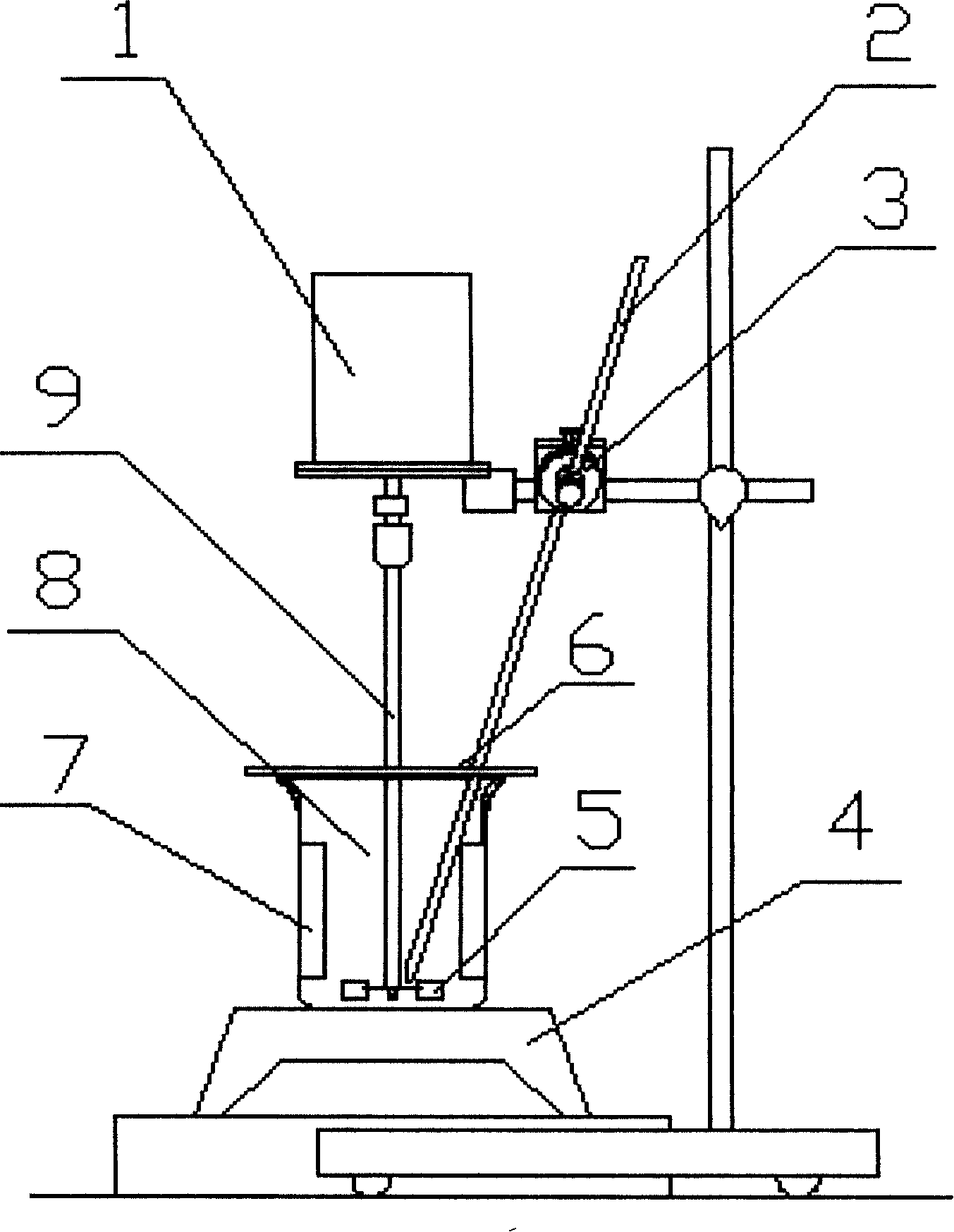

Method for leaching bidery metal by sulfuric acid and inflation agitation leaching trough

A white metal, leaching tank technology, applied in chemical instruments and methods, process efficiency improvement, solid separation, etc., can solve the problems of long leaching time, large oxygen consumption, long regeneration time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] Number of leaching stages: 1 stage;

[0146] Weigh white alloy 100g, according to liquid-solid ratio (L / S)=5:1 (ratio of sulfuric acid solution volume and alloy weight, above-mentioned liquid / solid=5:1 is 100 grams alloy powder is mixed with 500mL sulfuric acid solution, wherein sulfuric acid solution Concentration: 3.4mol / L, prepare leaching solution (the same below), H 2 SO 4 One input; the leaching time at 90°C is 4h (hours); the volume of the leaching solution (including washing water) is 940mL, containing Co24.03g / L; the leaching residue is 74.04g, containing Co23.86%; the cobalt leaching rate is 58.05%; (The slag count is the same below); Cu does not leach.

Embodiment 2

[0148] Except that the leaching conditions are: "liquid-solid ratio 8:1, temperature 100°C, stirring speed 600 rpm, leaching time 4h;" and test results: "leach solution 895mL, containing Co30.48g / L, SiO 2 0.17g / L; leaching residue 68.22g, containing Co20.72%; cobalt leaching rate 66.43%; copper not leaching. "External, all the other are identical with embodiment 1 described.

Embodiment 3

[0150] Except that the leaching conditions are: "liquid-solid ratio 5:1, temperature 100°C, stirring speed 1000 rpm, leaching time 4h;" and the test results are: "leaching solution 1017mL, containing Co23.78g / L; leaching residue 72.35g Containing Co23.56%; Cobalt leaching rate 59.52%; Copper is not leached." Outside, all the other are identical with embodiment 1 description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com