Car trim and preparation method of surface coating of car trim

A technology for automotive decoration and decorative parts, which is applied in coatings, vehicle parts, metal material coating processes, etc., and can solve problems such as damage to human health, high water and energy consumption, and easy fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

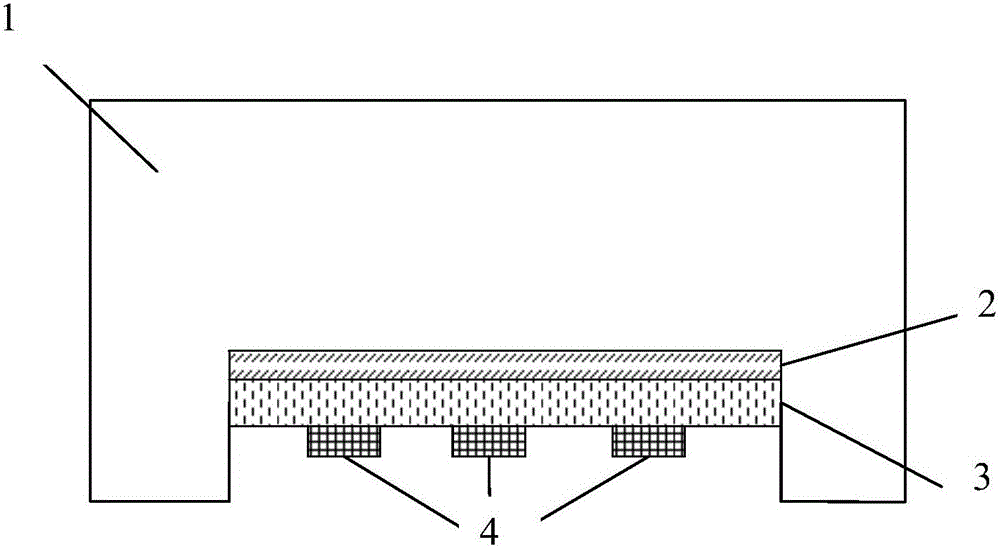

[0026] In this embodiment, the base material of the decorative part is PC, and there is a groove on the rear surface of the substrate. The groove is covered with a chromium coating with a thickness of 10nm and a diamond-like coating with a thickness of 200nm from the inside to the outside. Inductive visible light sources arranged in a certain shape.

[0027] The method for preparing the surface coating of the above-mentioned automobile trim comprises the steps of:

[0028] Step 1: Suspend the plastic substrate on the metal support and place it in a vacuum chamber. Introduce Ar gas so that the pressure in the chamber is 0.2Pa. Set the power of the ion source of the anode layer to 150W to ionize Ar, and apply to the metal support Pulse negative bias voltage -50V, use argon ion beam to etch the surface of the substrate, and the etching time is 5min;

[0029] Step 2: Introduce Ar gas into the coating chamber so that the pressure in the chamber is 0.3Pa, turn on the DC magnetron s...

Embodiment 2

[0033] In this embodiment, the base material of the decorative part is PC, and there is a groove on the rear surface of the substrate. The groove is covered with a chromium coating with a thickness of 50nm and a diamond-like coating with a thickness of 600nm from the inside to the outside. Inductive visible light sources arranged in a certain shape.

[0034] The method for preparing the surface coating of the above-mentioned automobile trim comprises the steps of:

[0035] Step 1: Suspend the plastic substrate on the metal support and place it in a vacuum chamber. Introduce Ar gas so that the pressure in the chamber is 0.3Pa. Set the power of the ion source of the anode layer to 150W to ionize Ar, and apply to the metal support Pulse negative bias voltage -100V, use argon ion beam to etch the surface of the substrate, and the etching time is 8min;

[0036] Step 2: Introduce Ar gas into the coating chamber so that the pressure in the chamber is 0.3Pa, turn on the DC magnetron ...

Embodiment 3

[0040] In this embodiment, the base material of the decorative part is PC, and there is a groove on the rear surface of the substrate. The groove is covered with a chromium coating with a thickness of 30nm and a diamond-like coating with a thickness of 300nm from the inside to the outside. Inductive visible light sources arranged in a certain shape.

[0041] The method for preparing the surface coating of the above-mentioned automobile trim comprises the steps of:

[0042] Step 1: Suspend the plastic substrate on the metal support and place it in a vacuum chamber. Introduce Ar gas so that the pressure in the chamber is 0.5Pa. Set the power of the ion source of the anode layer to 200W to ionize the Ar, and apply it to the metal support. Pulse negative bias voltage -200V, use argon ion beam to etch the surface of the substrate, and the etching time is 10min;

[0043]Step 2: Introduce Ar gas into the coating chamber so that the pressure in the chamber is 0.4Pa, turn on the DC ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com