Magnesium alloy pickling activator and pickling method

A technology of pickling activation and magnesium alloy, which is applied in the field of pickling activator and pickling, can solve the problems of animal and plant damage, excessive manpower and working hours, water source and soil pollution, etc., achieve mild reaction, save manpower and material resources, and clean powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

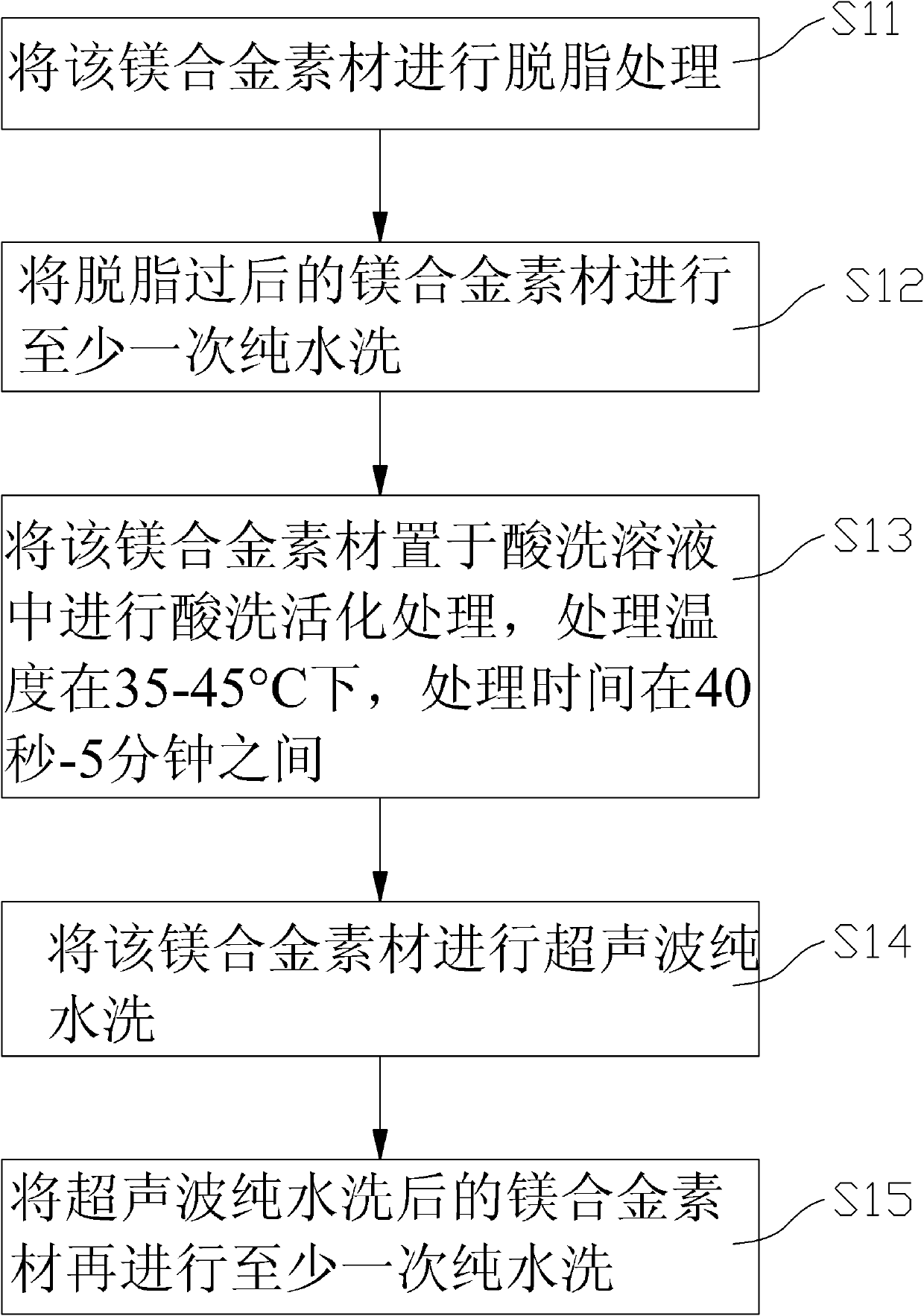

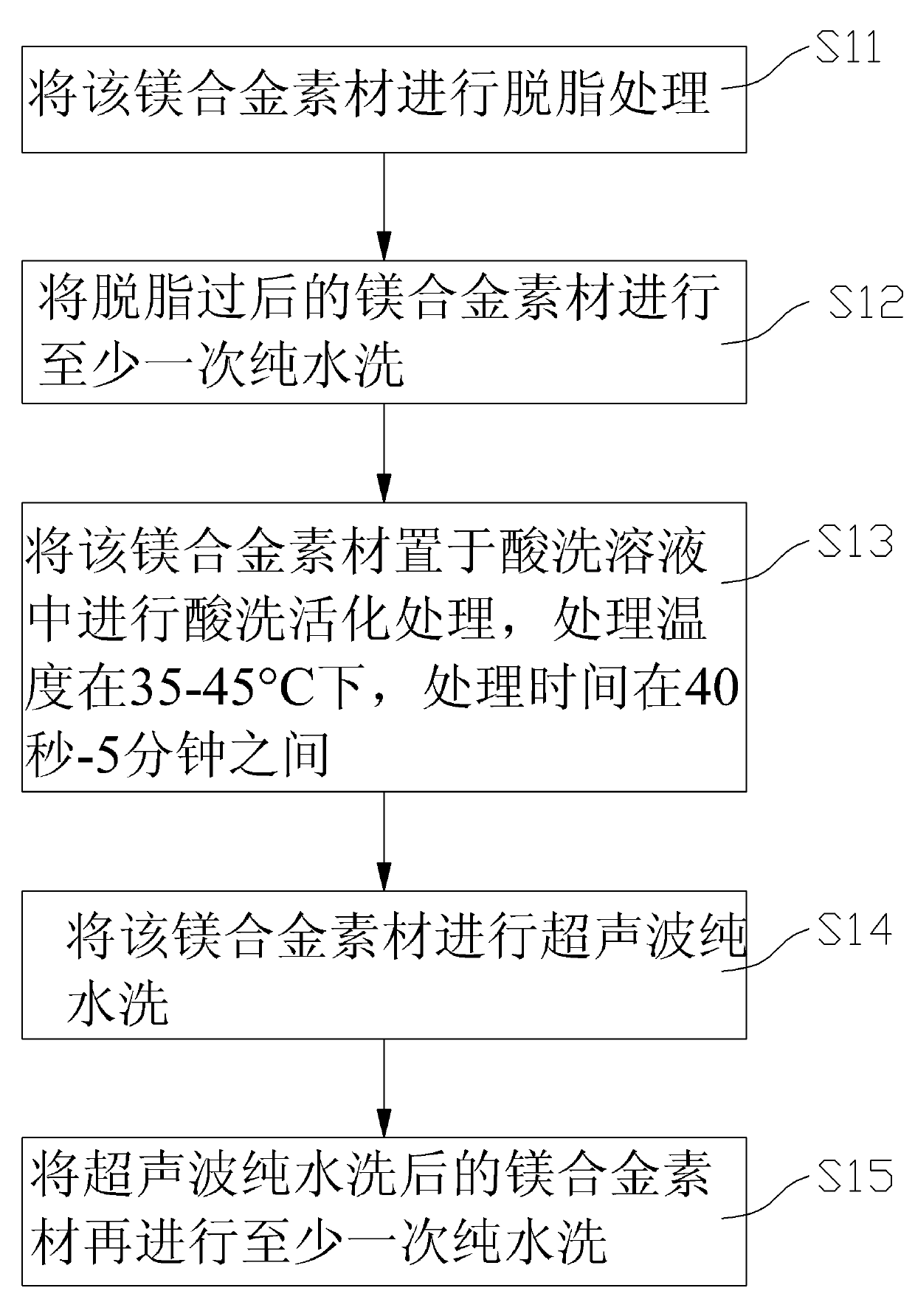

Method used

Image

Examples

Embodiment 1

[0034] First, after the magnesium alloy material is degreased and washed with water, the magnesium alloy material is placed in a pickling activator formulated according to the following composition concentration:

[0035] (a) citric acid 6g / L;

[0036] (b) Lactic acid 15g / L;

[0037] (c) Nitric acid 2g / L;

[0038] (d) Corrosion inhibitor 0.001g / L;

[0039] (e) Sodium acetate 3g / L;

[0040] Secondly, the magnesium alloy material is subjected to pickling and activation treatment, the treatment temperature is 42 degrees, and the treatment time is 4 minutes;

[0041] Finally, surface conditioning treatment and chemical conversion treatment are performed on the magnesium alloy material after the pickling treatment.

[0042] The atomic percentage (Atomic%) of the silicon element content in each stage of surface treatment of the magnesium alloy material after the pickling and activation treatment by the above-mentioned pickling activator was tested, and the results are as follows...

Embodiment 2

[0046] First, after the magnesium alloy material is degreased and washed with water, the magnesium alloy material is placed in a pickling activator formulated according to the following composition concentration:

[0047] (a) Citric acid 8g / L;

[0048] (b) Lactic acid 12g / L;

[0049] (c) Nitric acid 3g / L;

[0050] (d) Corrosion inhibitor 0.002g / L;

[0051] (e) Sodium acetate 4g / L;

[0052] Secondly, the magnesium alloy material is subjected to pickling and activation treatment, the treatment temperature is 38 degrees, and the treatment time is 3 minutes;

[0053] Finally, surface conditioning treatment and chemical conversion treatment are performed on the magnesium alloy material after the pickling treatment.

[0054] The atomic percentage (Atomic%) of the silicon element content in each stage of surface treatment of the magnesium alloy material after the pickling and activation treatment by the above-mentioned pickling activator was tested, and the results are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com