Alkaline scale remover for magnesium alloy

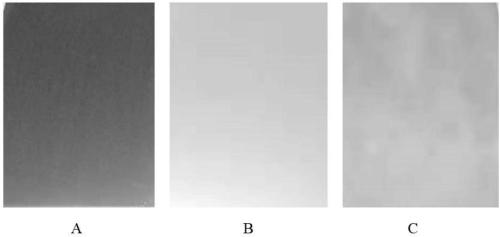

A descaling agent and magnesium alloy technology, applied in the field of magnesium alloy alkaline descaling agent, can solve the problems of polluting the environment, unfavorable to the health of workers, easy to generate harmful gases, etc., achieve uniform surface of the substrate, protect the environment and human health, more cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

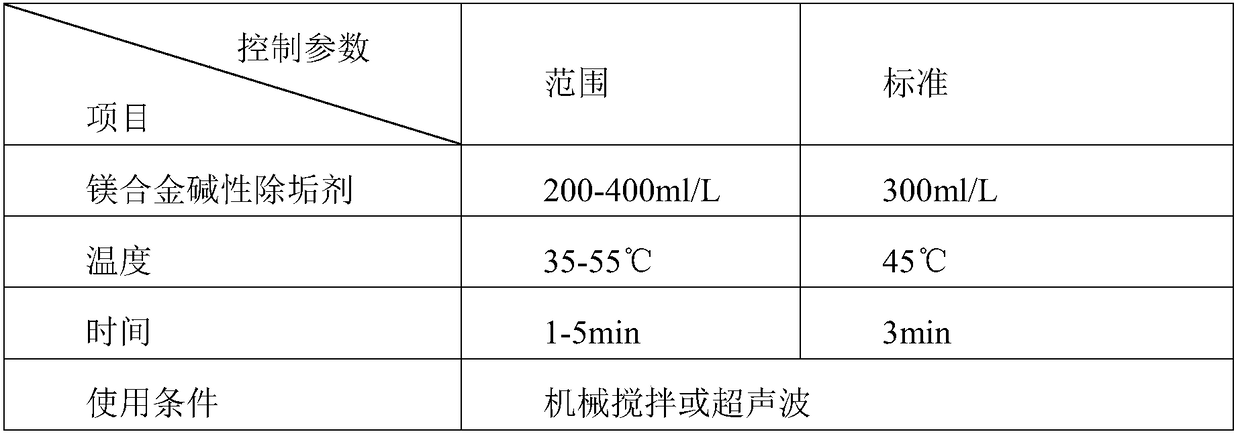

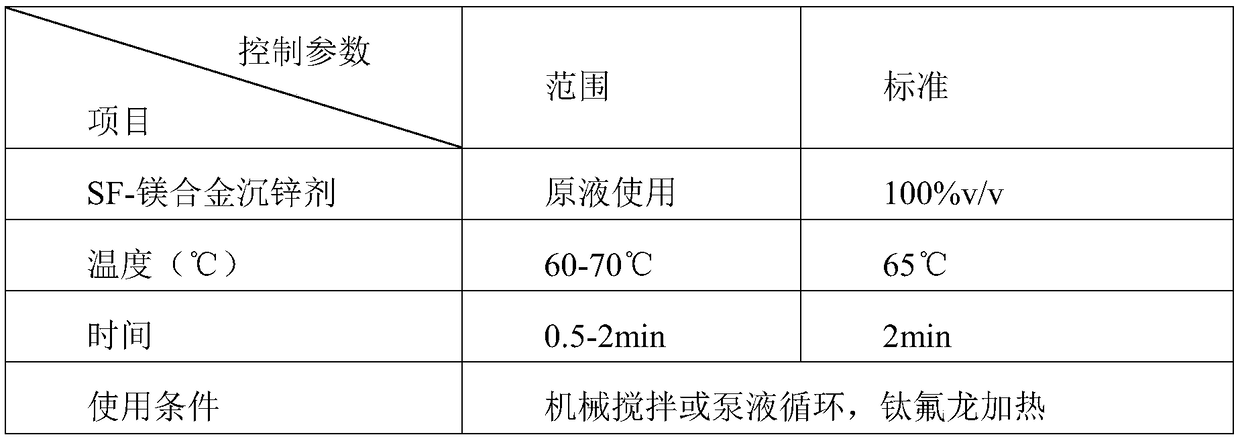

Method used

Image

Examples

Embodiment 1

[0022] The magnesium alloy alkaline descaling agent of the present embodiment comprises the component of following content:

[0023] Compound alkali 170g / Kg, complexing agent 35g / Kg, activator 13g / Kg, corrosion inhibitor 45g / Kg, desorption agent 1g / Kg, and the rest water. Wherein, compound base is provided by sodium hydroxide, salt of wormwood (sodium hydroxide 130g / Kg, potassium carbonate 40g / Kg); Complexing agent is provided by sodium glucoheptonate and phytic acid (sodium glucoheptonate content 20g / Kg, phytic acid 15g / Kg); Activator is provided by potassium fluoride and triethanolamine (potassium fluoride 8g / Kg, triethanolamine 5g / Kg); Corrosion inhibitor is provided by sodium nitrate; Desorption agent is provided by alkane Glycoside (AG6202 from Aksu Company) and EO-PO polymer (BL240, Solvay Company) to provide (0.6g / Kg for AG6202, 0.4g / Kg for BL240).

Embodiment 2

[0025] The magnesium alloy alkaline descaling agent of the present embodiment comprises the component of following content:

[0026] Compound alkali 200g / Kg, complexing agent 50g / Kg, activator 10g / Kg, corrosion inhibitor 30g / Kg, desorption agent 3g / Kg, and the rest water. Wherein, the complex base is provided by potassium hydroxide, sodium silicate and sodium carbonate (potassium hydroxide 150g / Kg, sodium silicate 30g / Kg, sodium carbonate 20g / Kg); sodium phosphate and polyacrylamide (disodium EDTA content 30g / Kg, sodium glucoheptonate 15g / Kg polyacrylamide 5g / Kg); activator is provided by sodium fluoride and ammonia water (sodium fluoride 6g / Kg , ammoniacal liquor 4g / Kg); Corrosion inhibitor is provided by sodium nitrite and urea (sodium nitrite content is 20g / Kg, and urea content is 10g / Kg); Desorption agent is provided by betaine and AEO-7 (beet Alkali is 1g / Kg, AEO-7 is 2g / Kg).

Embodiment 3

[0028] The magnesium alloy alkaline descaling agent of the present embodiment comprises the component of following content:

[0029] Compound alkali 240g / Kg, complexing agent 30g / Kg, activator 8g / Kg, corrosion inhibitor 50g / Kg, desorption agent 2g / Kg, and the rest water. Wherein, compound base is provided by sodium silicate, potassium silicate, potassium carbonate (sodium silicate 100g / Kg, potassium silicate 110g / Kg, potassium carbonate 30g / Kg); complexing agent is by sodium glucoheptonate and phenol Sulfonic acid is provided (sodium glucoheptonate content 25g / Kg, phenol sulfonic acid 5g / Kg), the activator is provided by ammonium hydrogen fluoride and sodium fluoroborate (amine hydrogen fluoride 4g / Kg, sodium fluoroborate 4g / Kg), slow The etchant is provided by benzotriazole, and the desorbent is provided by diethylene glycol monobutyl ether and EO-PO polymer (BL240, Solvay Company) (diethylene glycol monobutyl ether is 1.5g / Kg, BL240 is 0.5g / Kg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com