Novel block polyisocyanate and urethane composition containing the same

A polyisocyanate, isocyanate-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased energy cost, insufficient coating hardness, carbon dioxide gas generation, etc., to achieve excellent weather resistance, high coating hardness, The effect of excellent low temperature curability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

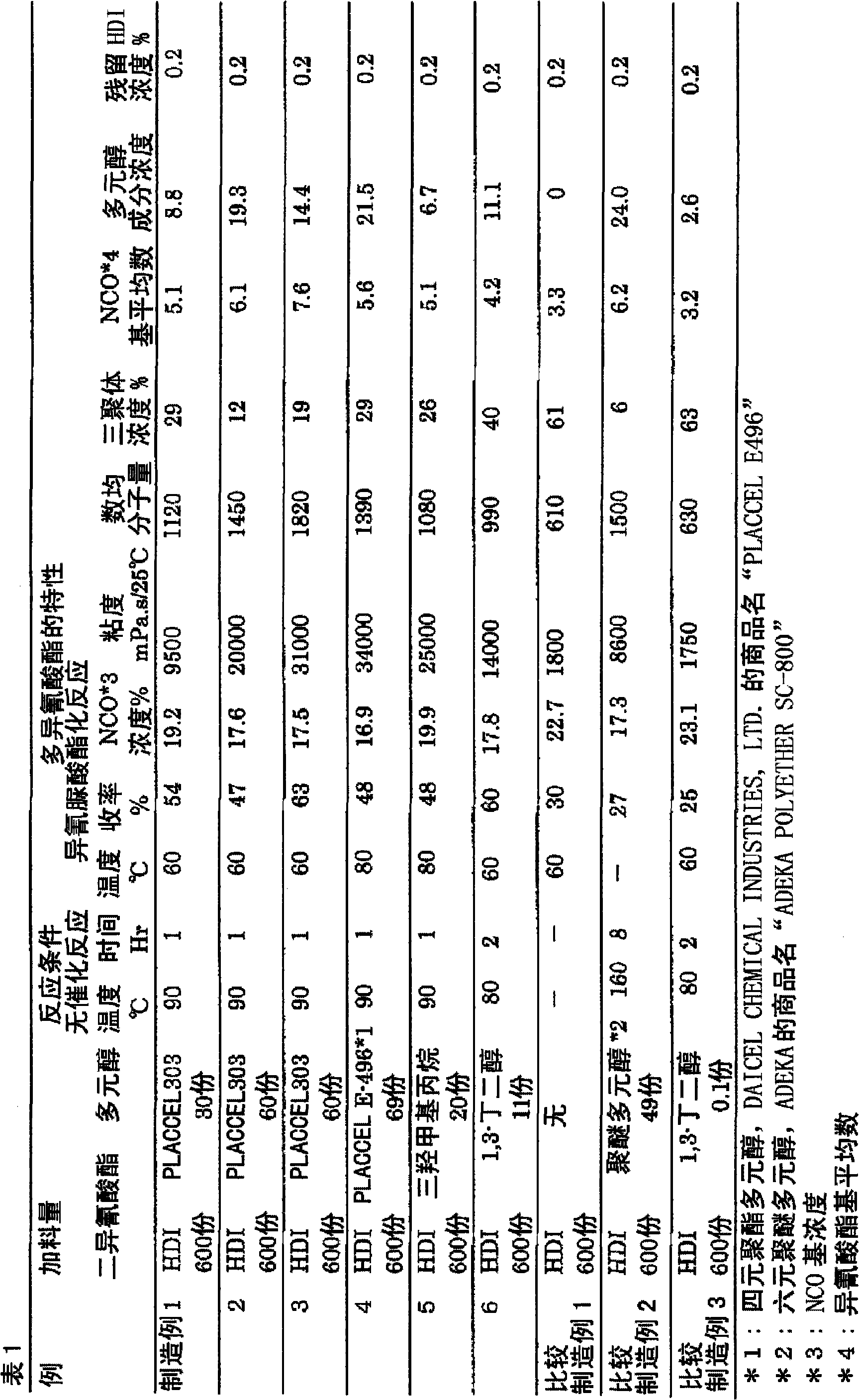

[0097] (Manufacture example 1: Manufacture of polyisocyanate)

[0098] Make a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen gas introduction tube, and a dropping funnel in a nitrogen atmosphere, and add 600 parts of HDI and 30 parts of polycaprolactone-based polyester triol as a triol " PLACCEL 303" (trade name of DAICELCHEMICAL INDUSTRIES, LTD., molecular weight 300), under stirring, the temperature in the reactor was kept at 90°C for 1 hour to carry out pre-reaction. Thereafter, the temperature in the reactor was kept at 80° C., tetramethylammonium octanoate was added as a catalyst for the isocyanuration reaction, and when the yield reached 54%, phosphoric acid was added to stop the reaction. After filtering the reaction solution, unreacted HDI was removed using a thin film evaporation tank. The obtained polyisocyanate had a viscosity of 9500 mPa·s at 25°C, an isocyanate group content of 19.2% by mass, a number average molecular we...

manufacture example 2~6

[0100] Production was carried out in the same manner as in Production Example 1 except that the feed composition and reaction conditions shown in Table 1 were used. Table 1 shows the results of properties of the obtained polyisocyanate.

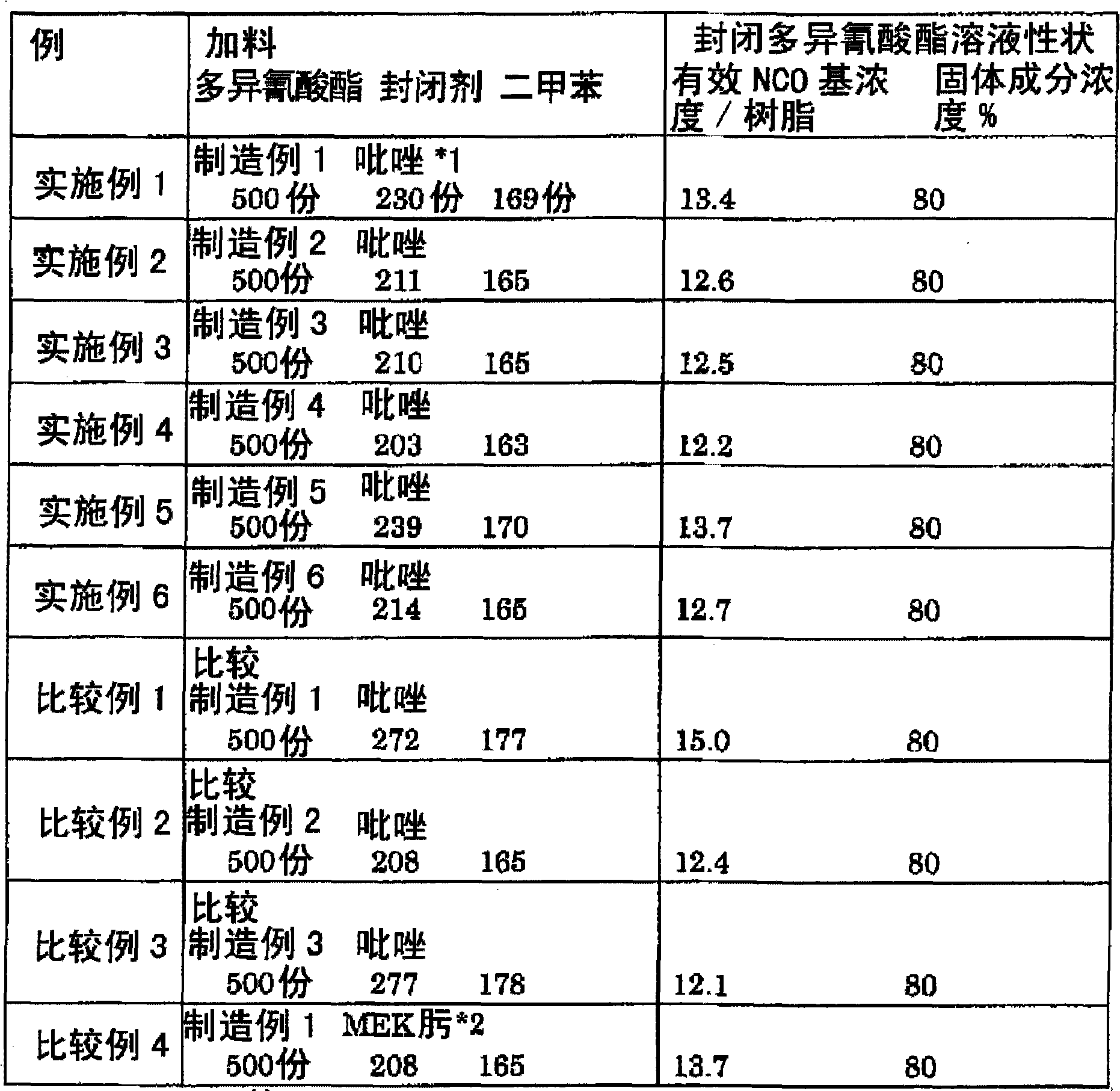

Embodiment 1

[0108] A four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen gas introduction tube, and a dropping funnel was made into a nitrogen atmosphere, and 500 parts of the polyisocyanate obtained in Production Example 1 and 169 parts of xylene were added and mixed. Further, 230 parts of 3,5-dimethylpyrazole (isocyanate group / 3,5-dimethylpyrazole=1.05 (equivalent ratio)) were added and mixed. The temperature of this mixed solution was raised to 60°C. Hold until the characteristic absorption of the isocyanate group disappears when the mixed solution is sampled and measured by infrared spectroscopy.

[0109] The blocked polyisocyanate (curing agent) of the present invention having a solid content of 80% by mass and an effective isocyanate group concentration of 13.4% (blocked polyisocyanate basis) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com