Screen printing conductive adhesive with excellent scratch resistance

A technology of screen printing and conductive adhesive, used in conductive coatings, conductive adhesives, adhesives, etc., can solve the problem that it is difficult to achieve high hardness, does not give pencil hardness and bending resistance, and cannot achieve halogen-free. standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

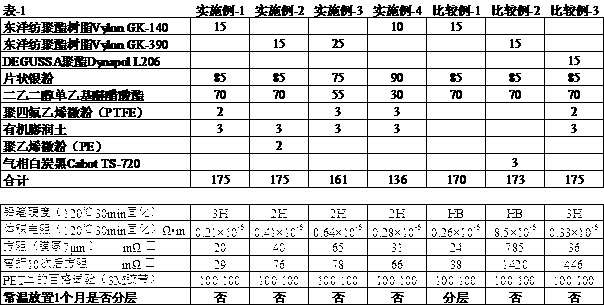

Embodiment -1

[0029] 【 Example-1 】The polyester resin is commercially available Japan Toyobo VYLON GK-140, the glass transition temperature (Tg) is 20 degrees, and the pencil hardness of the polyester resin body is H. Dissolve 15g of polyester resin in 70g of diethylene glycol monoethylene In the base ether acetate high boiling point solvent, heat to 80 degrees until the resin is completely dissolved and becomes transparent. Add 85g of flake silver powder, 2g of polytetrafluoroethylene micropowder, and 3g of organic bentonite, mix evenly with a planetary mixer, and then grind with a three-roll mill for 3 times. The prepared conductive adhesive is printed on PET polyester film with 80 mesh screen printing to make a test piece with a width of 1 cm and a length of 5 cm. After drying in a blast drying oven at 120 degrees for 30 minutes, test square resistance, bending performance, volume resistance, and pencil hardness. And adhesion (100 grid test). The results are shown in Table 1.

Embodiment -2

[0030] 【 Example-2 】Toyobo VYLON GK-390 is used as the polyester resin, the Tg is 7 degrees, the pencil hardness of the resin body is HB, polyethylene micropowder is used instead of polytetrafluoroethylene micropowder, other raw materials and preparation process are the same as in Example-1.

Embodiment -3

[0031] 【 Example - 3, 4 】The proportion of polyester resin (Binder) and silver powder and the amount of solvent were changed, and the other raw materials and preparation process were the same as in Example-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com