Preparation method of waterproof and whiting-resistant silicon-acrylic composite emulsion for interior wall latex coatings

A technology of latex paint and composite emulsion, applied in latex paint, coating and other directions, can solve the problems of difficult migration of silicone molecular chains, limited improvement of composite resin performance, complicated operation, etc., and achieves good mechanical stability and storage stability. Excellent water whitening resistance and water resistance, and the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

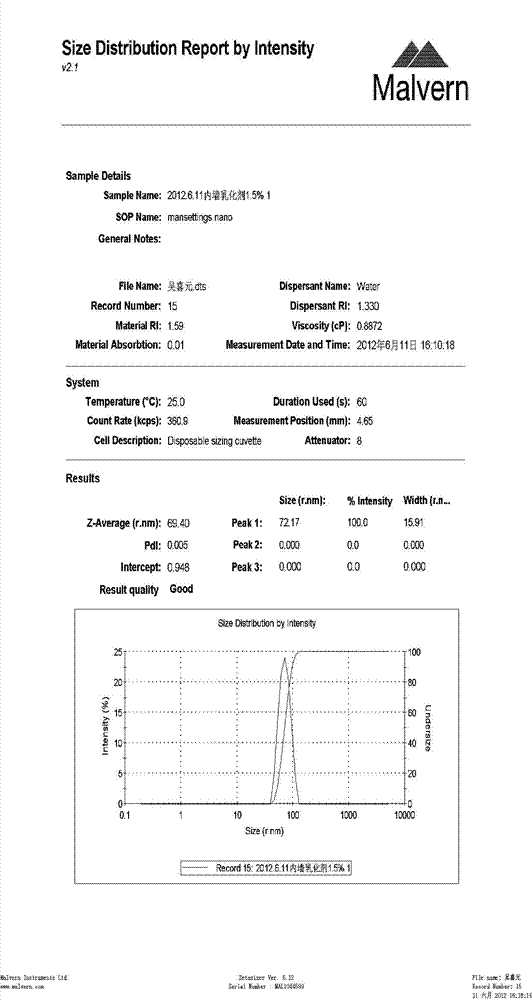

Image

Examples

Embodiment 1

[0042] The composition of the mass fraction of raw materials is:

[0043] Monomer 46wt%

[0044] Of which: methyl methacrylate 46wt%

[0045] Butyl acrylate 39wt%

[0046] Styrene 5wt%

[0047] Methacrylic acid 2wt%

[0048] Tetramethyl divinyl disiloxane 3wt%

[0049] Diacetone acrylamide 0.5wt%

[0050] Adipic acid dihydrazide 0.5wt%

[0051] Hydroxybutyl acrylate 4wt%

[0052] Compound emulsifier

[0053] Nonylphenol polyoxyethylene ether sulfosuccinic acid monoester disodium salt 1.6wt%

[0054] Sodium lauryl sulfate 0.4wt%

[0055] Initiator ammonium persulfate 1.0wt%

[0056] The rest is deionized water;

[0057] The specific preparation method is as follows: dissolve 30wt% emulsifier with 35wt% deionized water accounting for the total amount of pre-emulsified monomers, and then pour it into pre-mixed tetramethyldivinyldisiloxane and diacetone acrylamide. , Hydroxybutyl acrylate, methacrylic acid, 60wt% methyl methacrylate and 60wt% butyl acrylate mixture, emulsify at a low speed at 600rpm...

Embodiment 2

[0059] The composition of the mass fraction of raw materials is:

[0060] Monomer 48wt%

[0061] Of which: methyl methacrylate 45wt%

[0062] Butyl acrylate 38wt%

[0063] Styrene 5wt%

[0064] Methacrylic acid 2wt%

[0065] Vinyl silicone oil DY-V401 4wt%

[0066] Diacetone acrylamide 1wt%

[0067] Adipic acid dihydrazide 1wt%

[0068] Hydroxyethyl acrylate 4wt%

[0069] Compound emulsifier

[0070] Nonylphenol polyoxyethylene ether sulfosuccinic acid monoester disodium salt 2.4wt%

[0071] Sodium lauryl sulfate 0.6wt%

[0072] Initiator ammonium persulfate 0.8wt%

[0073] The rest is deionized water;

[0074] The specific preparation method is as follows: dissolve 35wt% of the composite emulsifier with 40wt% deionized water accounting for the total amount of pre-emulsified monomers, and then pour it into pre-mixed vinyl silicone oil DY-V401, diacetone acrylamide, acrylic acid hydroxy Ethyl, methacrylic acid, 65wt% methyl methacrylate and 65wt% butyl acrylate mixture are emulsified at a low spe...

Embodiment 3

[0076] The composition of the mass fraction of raw materials is:

[0077] Monomer 48wt%

[0078] Of which: methyl methacrylate 46wt%

[0079] Butyl acrylate 39wt%

[0080] Styrene 5wt%

[0081] Methacrylic acid 2wt%

[0082] Tetramethyltetravinylcyclotetrasiloxane 3wt%

[0083] Diacetone acrylamide 1wt%

[0084] Succinic acid dihydrazide 1wt%

[0085] Hydroxypropyl acrylate 3wt%

[0086] Compound emulsifier

[0087] Nonylphenol polyoxyethylene ether sulfosuccinic acid monoester disodium salt 2.4wt%

[0088] Sodium lauryl sulfate 0.6wt%

[0089] Initiator ammonium persulfate 1.0wt%

[0090] The rest is deionized water;

[0091] The specific preparation method is as follows: dissolve 35wt% emulsifier with 40wt% deionized water, which accounts for the total amount of pre-emulsified monomers, and then pour it into pre-mixed tetramethyltetravinylcyclotetrasiloxane and diacetone propylene. In the mixed liquid of amide, hydroxypropyl acrylate, 70wt% of methyl methacrylate and 70wt% of butyl acrylate, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com