Water-based fluorine-containing polyurethane paint and preparation method thereof

A technology of polyurethane coating and polyurethane resin, which is applied in the field of water-based fluorine-containing polyurethane coating and its preparation, can solve the problems of limited popularization and application, the hardness of glossy pencils cannot meet the basic performance requirements, and it is difficult to meet high-performance coatings. Low polarizability, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

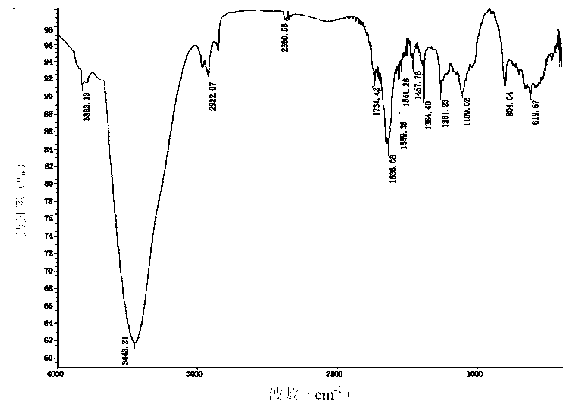

Image

Examples

Embodiment 1

[0070] A water-based fluorine-containing polyurethane coating, calculated in parts by weight, its raw material composition and content are as follows:

[0071] Bayhydur XP 2655 5 copies

[0072] Water-based hydroxyl fluorine-containing polyurethane resin 60 parts

[0073] Leveling agent 0.05 parts

[0074] 1 part wetting agent

[0075] 1 part thickener

[0076] 0.2 parts of defoamer

[0077] Coalescing aid 2 parts

[0078] Catalyst A 0.02 parts

[0079] 20 parts deionized water

[0080] Bayhydur XP 2655 described therein is the hydrophilic modified aliphatic polyisocyanate curing agent of German Bayer Company;

[0081] Described leveling agent is BYK 346 of BYK company;

[0082] Described wetting agent is NP-100 of U.S. Dow Company;

[0083] Described thickener is RM 825 of Rohm and Haas Co., Ltd.;

[0084] Described defoamer is the Nopco NXZ of German Henkel Company;

[0085] Described film-forming aid is the dipropylene glycol butyl ether of U.S. Dow Chemical Comp...

Embodiment 2

[0128] A water-based fluorine-containing polyurethane coating, calculated in parts by weight, its raw material composition and content are as follows:

[0129] Bayhydur XP 2655 8 copies

[0130] Water-based hydroxyl fluorine-containing polyurethane resin 70 parts

[0131] Leveling agent 0.1 part

[0132] Wetting agent 10 parts

[0133] thickener 3 parts

[0134] 1 part defoamer

[0135] Catalyst A 1.0 parts

[0136] Coalescing aid 5 parts

[0137] 40 parts deionized water

[0138] Bayhydur XP 2655 described therein is the hydrophilic modified aliphatic polyisocyanate curing agent of German Bayer Company;

[0139] Described leveling agent is BYK 346 of BYK company;

[0140] Described wetting agent is NP-100 of U.S. Dow Company;

[0141] Described thickener is RM 825 of Rohm and Haas Co., Ltd.;

[0142] Described defoamer is the Nopco NXZ of German Henkel Company;

[0143] Described film-forming aid is the dipropylene glycol butyl ether of U.S. Dow Chemical Company; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com