Iron-based cored wire including amorphous phase abrasion-resistant and corrosion-resistant coating prepared by utilizing electric arc spraying and preparation method of coating

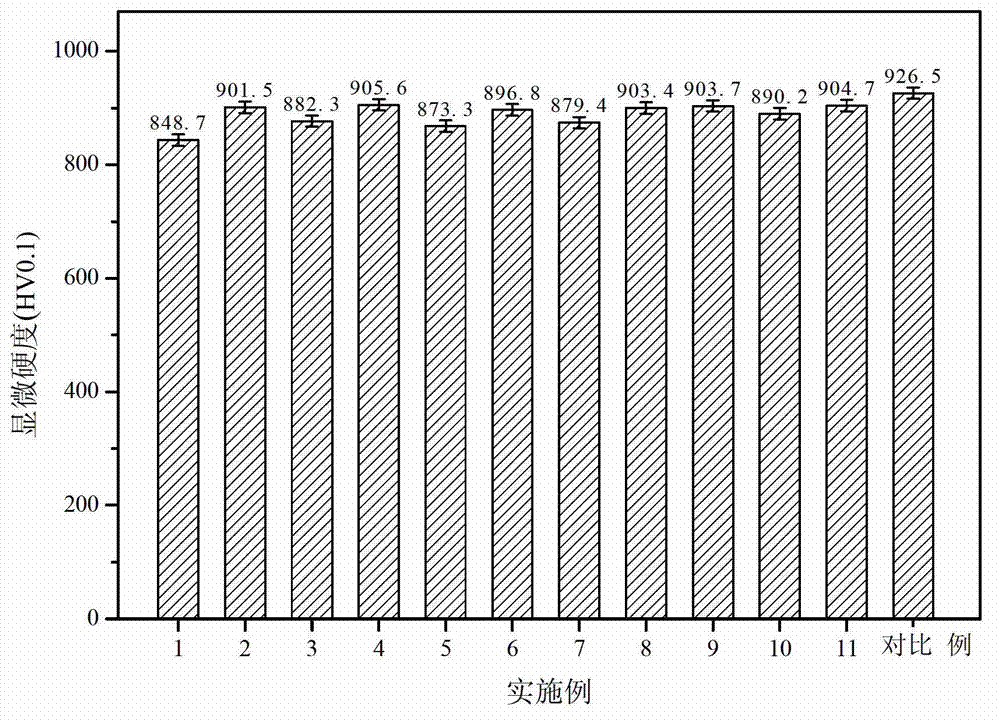

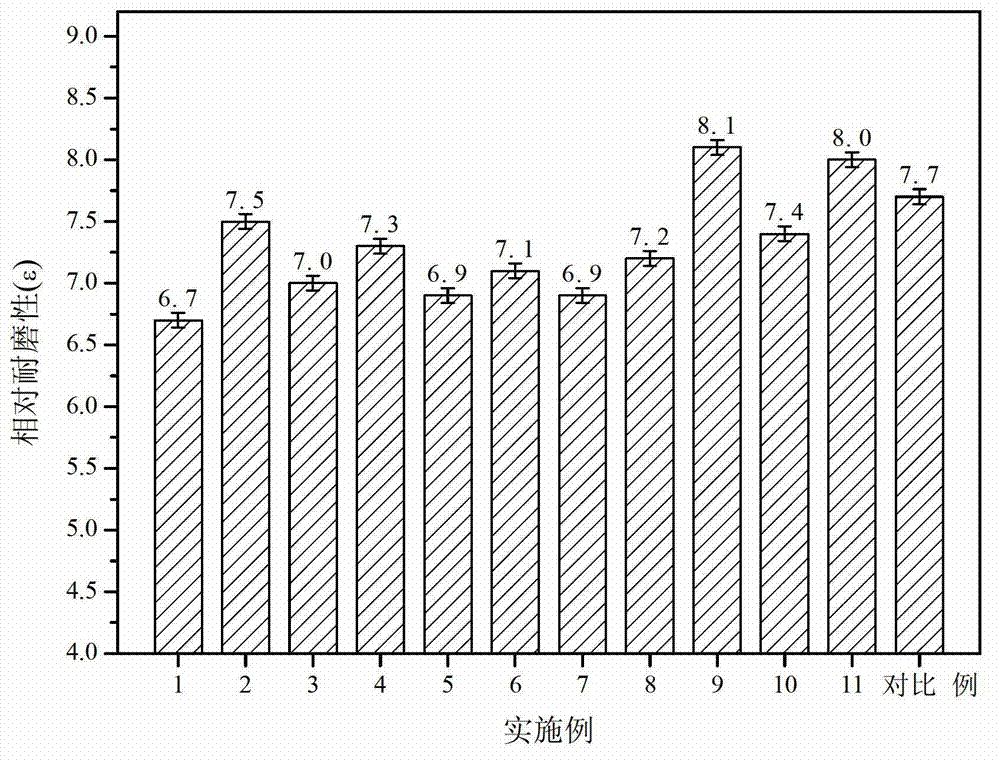

A technology of powder core wire material and arc spraying, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems that are not suitable for engineering applications, the brittleness of amorphous coatings, etc., and achieve good electrochemical resistance Good corrosion resistance, good wear resistance, and high coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the atomic percentage of each element in the powder core wire material: Cr: 15at.%; P: 4at.%; Si: 9at.%; C: 2at.%; Fe and unavoidable impurities: balance; filling rate: 32%, Rolled powder core wire. Process parameters used for coating preparation: voltage 25-30V; current 180-200A; spraying distance 190mm; compressed air pressure 0.4-0.5MPa.

Embodiment 2

[0035] According to the atomic percentage of each element in the powder core wire material: Cr: 15at.%; P: 4at.%; Si: 9at.%; C: 2at.%; Fe and unavoidable impurities: balance; filling rate: 34%, Rolled powder core wire. Process parameters used for coating preparation: voltage 30-34V; current 200-220A; spraying distance 200mm; compressed air pressure 0.5-0.6MPa.

Embodiment 3

[0037] According to the atomic percentage of each element in the powder core wire material: Cr: 20at.%; P: 10at.%; Si: 12at.%; C: 2at.%; Fe and unavoidable impurities: balance; filling rate: 32%, Rolled powder core wire. Process parameters used for coating preparation: voltage 25-30V; current 180-200A; spraying distance 190mm; compressed air pressure 0.4-0.5MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com