High-strength and high-hardness magnesium alloy in controllable reaction with water, and manufacturing method of component thereof

A manufacturing method and technology of magnesium alloys, applied in the field of magnesium alloys in the field of metal materials technology, can solve problems such as no description or report found, and no information has been searched, and achieve the effect of high hardness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

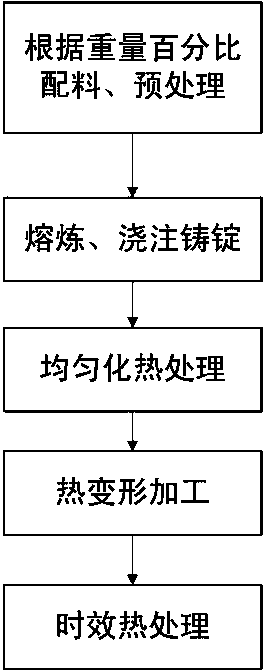

Method used

Image

Examples

Embodiment 1

[0022] Manufacture magnesium alloy components with a weight percentage of Mg-9.0%Gd-3.0%Y-0.4%Cu-0.4Zn%-0.05% MRAE, Mg is the balance, and the total weight percentage of impurity elements Be, Zr, and Ca is less than 0.01%. Include the following steps.

[0023] Pretreatment step: weighing magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, nickel, gallium, indium and other raw materials by weight percentage, wherein magnesium, magnesium-gadolinium master alloy , Magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, and nickel are preheated at 200°C for 8 hours.

[0024] Melting and pouring steps: It is recommended to melt in a crucible resistance furnace, add covering agent JDMF for covering, and refining agent RJ6 for refining treatment, so that the alloy components are evenly mixed, remove inclusions, pour at 680°C to obtain...

Embodiment 2

[0030] Manufacture magnesium alloy components with a weight percentage of Mg-12.0%Gd-4.0%Y-0.9%Cu-0.8Zn%-0.9%MRAE, Mg is the balance, and the total weight percentage of impurity elements Be, Zr, and Ca is less than 0.01%. Include the following steps.

[0031] Pretreatment step: weighing magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, nickel, gallium, indium and other raw materials by weight percentage, wherein magnesium, magnesium-gadolinium master alloy , Magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, and nickel are preheated at 200°C for 8 hours.

[0032] Melting and pouring steps: It is recommended to melt in a crucible resistance furnace, add covering agent JDMF for covering, and refining agent RJ6 for refining treatment, so that the alloy components are evenly mixed, remove inclusions, and cast at 700 ° C to o...

Embodiment 3

[0038] Manufacture magnesium alloy components with a weight percentage of Mg-15.0%Gd-5.0%Y-1.4%Cu-1.2Zn%-1.8%MRAE, Mg is the balance, and the total weight percentage of impurity elements Be, Zr, and Ca is less than 0.01%. Include the following steps.

[0039] Pretreatment step: weighing magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, nickel, gallium, indium and other raw materials by weight percentage, wherein magnesium, magnesium-gadolinium master alloy , Magnesium-yttrium master alloy, copper, zinc, magnesium-silicon master alloy, magnesium-iron master alloy, and nickel are preheated at 200°C for 8 hours.

[0040] Melting and pouring steps: It is recommended to melt in a crucible resistance furnace, add covering agent JDMF for covering, and refining agent RJ6 for refining treatment, so that the alloy components are evenly mixed, remove inclusions, and cast at 720 ° C to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com