Spherical crystalline silicon carbide powder and method for manufacturing same

A technology of silicon carbide powder and manufacturing method, which is applied in the direction of silicon carbide, carbide, transportation and packaging, etc., can solve the problems of incomplete densification, high cost, unavailable spherical crystal silicon carbide powder, etc., and achieve high utilization value, Effect of high thermal conductivity, excellent dielectric properties and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

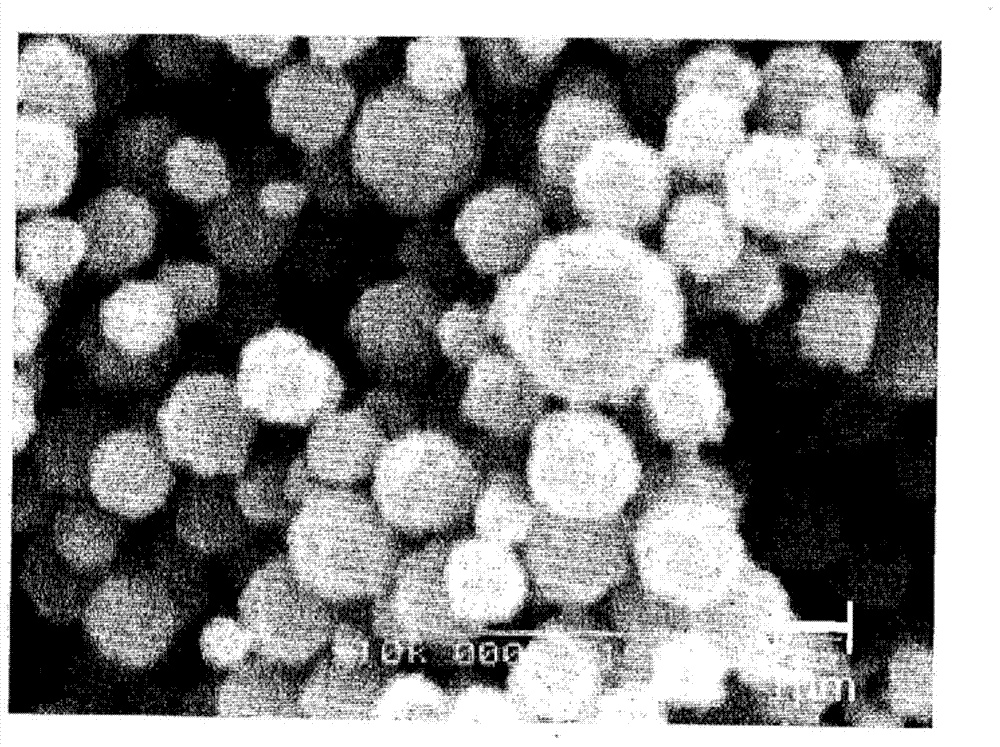

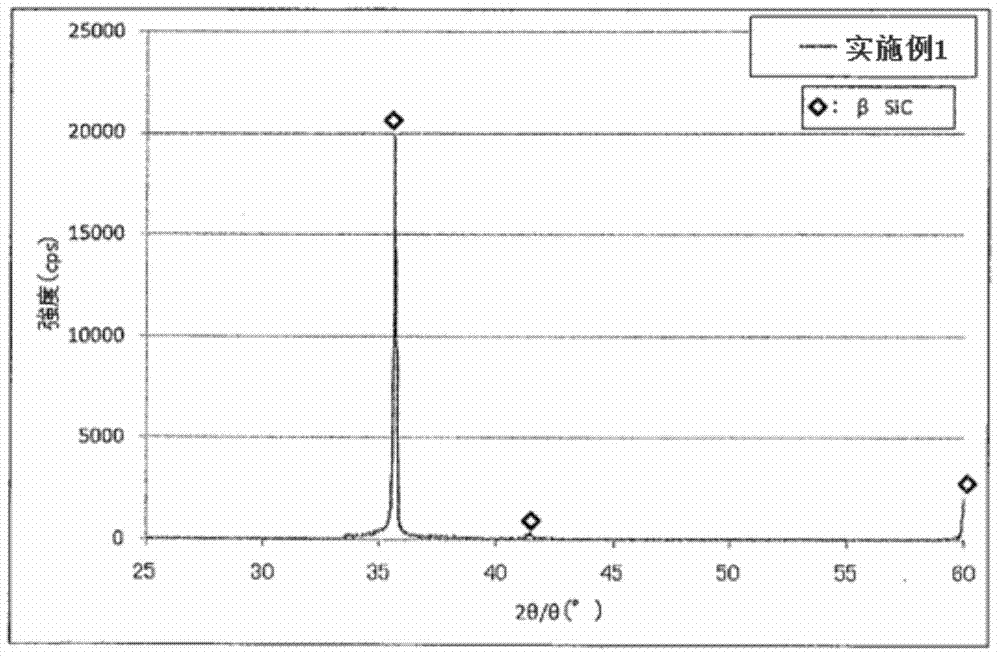

[0055] In Example 1, powder obtained by mixing spherical phenolic resin with an average particle size of 1.5 μm and silica AEROSIL with an average particle size of 0.02 μm at a weight ratio of phenolic resin / silica of 1.30 was charged into the high-frequency An induction heating furnace was heated to 1000° C. in an argon atmosphere and kept at 1000° C. for 1 hour, thereby calcining the spherical resin. Then, it was heated to 2200° C. and kept at 2200° C. for 2 hours to obtain a synthesized SiC powder. The synthesized SiC powder was kept at 700°C for 3 hours in a resistance heating furnace to remove unreacted carbon, thus obtaining figure 1 Shown are spherical particles with an average particle size of about 1.0 μm. Depend on figure 2 From the X-ray diffraction pattern shown, it can be seen that the obtained spherical particles are β-crystal SiC. In addition, in this spherical SiC, the internal pore volume with an average pore diameter of 0.05 μm is 0.00002 cc / g, and the s...

Embodiment 2

[0057] In Example 2, the treatment was performed under the same conditions as in Example 1, except that the weight ratio of the phenolic resin / silica was 1.13, and the reaction temperature after firing was 1800°C. As a result, SiC spherical particles having an average particle diameter of about 1 μm were obtained. It can be seen from the X-ray diffraction pattern that the obtained spherical SiC particles are β-type crystal SiC, and its specific surface area is 2.7m 2 / g.

Embodiment 3

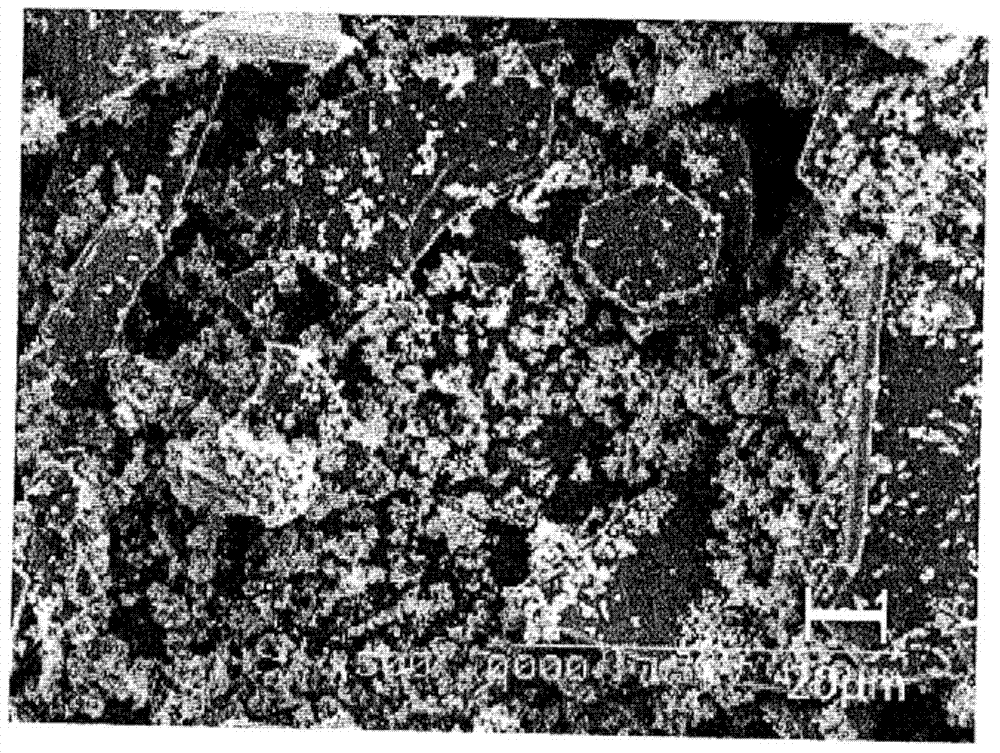

[0061] In Example 3, the powder obtained by mixing spherical furan resin with an average particle diameter of 2.5 μm and silica AEROSIL with an average particle diameter of 0.02 μm at a furan resin / silica weight ratio of 1.60 was charged into a high-frequency An induction heating furnace was heated to 1000° C. in an argon atmosphere and kept at 1000° C. for 1 hour, thereby calcining the spherical resin. Then, it was heated to 2000° C. and kept at 2000° C. for 2 hours to obtain a synthesized SiC powder. The synthesized SiC powder was kept at 700°C for 3 hours in a resistance heating furnace to remove unreacted carbon, thus obtaining Figure 4 Shown are spherical particles with an average particle size of about 1.7 μm. Depend on Figure 5 From the X-ray diffraction pattern shown, it can be seen that the obtained spherical particles are β-crystal silicon carbide. In addition, in this spherical SiC, the internal pore volume with an average pore diameter of 0.05 μm is 0.0003 cc / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com