Machining process for carrying out local solid solution strengthening on valve disc neck portion and valve rod

A technology of solid solution strengthening and processing technology, which can be used in manufacturing tools, furnaces, heat treatment equipment, etc., and can solve the problems of complex valve stem shape, complex process and high solution cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

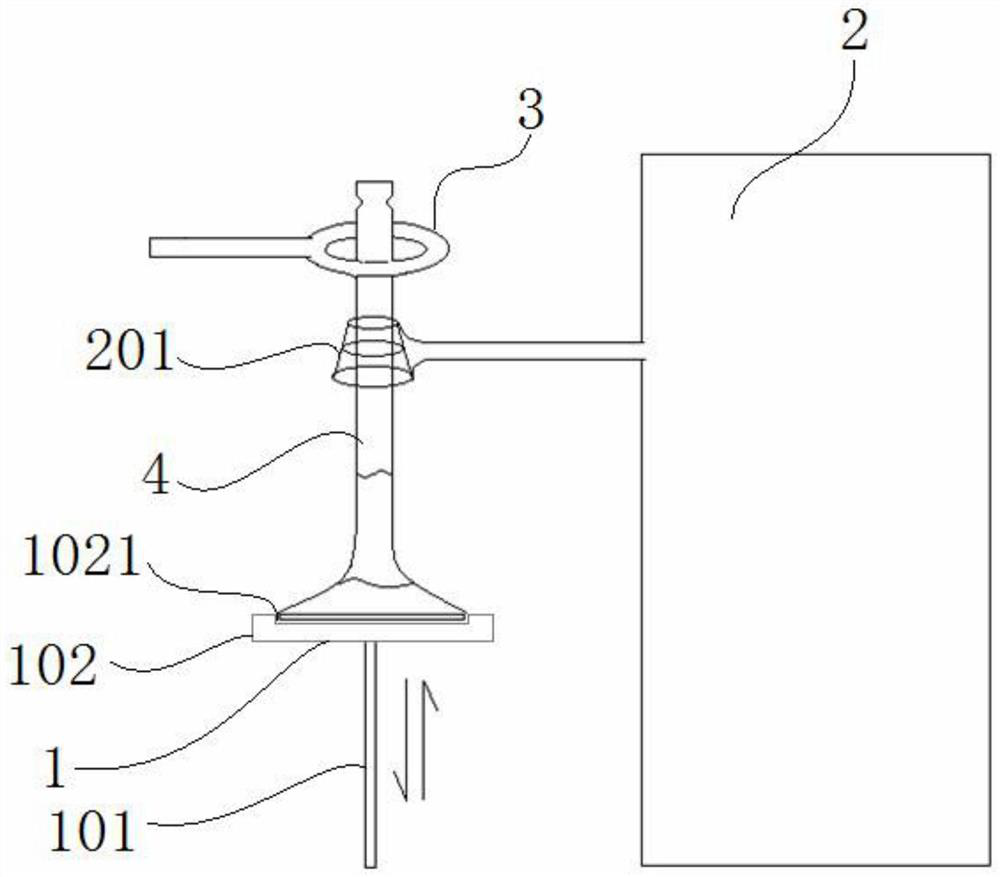

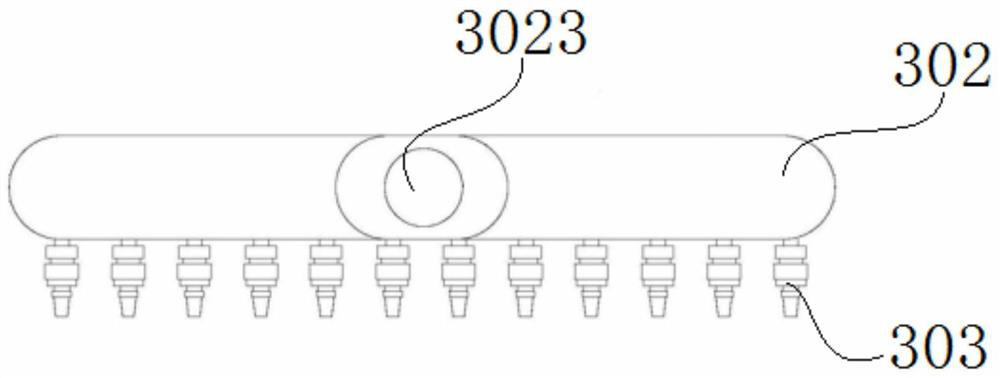

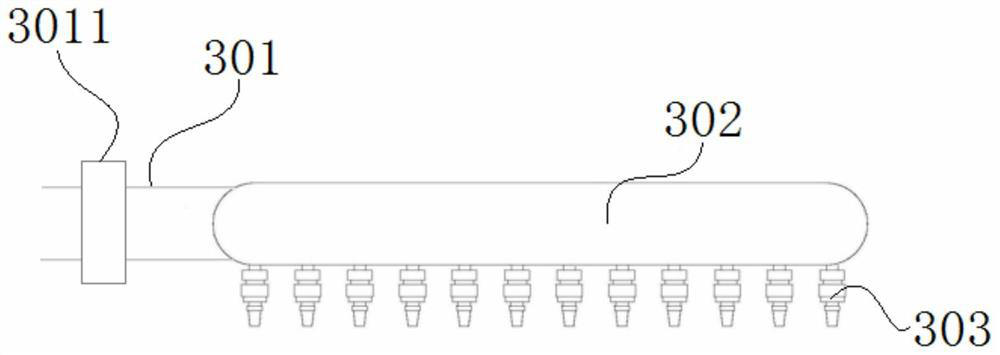

[0035]This example discloses a partial solid solution hardening process for the gas veneer neck, seeFigure 1 to 5 , Including the following steps:

[0036]1) Forming the valve rod blank 4 using a bacteric austenite valve steel material forging. Among them, the valve rod blank 4 is sequentially from the bottom to the umbrella portion 401, the tray 402, the rod portion 403, and the small end 404.

[0037]2) The small end 404 of the valve rod blank 4 and the umbrella portion 401 are solder.

[0038]3) Place the umbrella portion 401 of the valve rod blank 4 is placed on the positioning clamp assembly 102 of the feed positioning device 1. Wherein, the feed positioning device 1 includes a telescopic rod 101 and a positioning clamp assembly 102. The positioning clamp assembly 102 is fixed to the upper end portion of the telescopic rod 101. Specifically, the positioning clamp assembly 102 is a positioning plate, and there is a threaded hole on the bottom surface of the positioning plate, and the end...

Embodiment 2

[0052]This embodiment provides a relatively basic implementation, a local solid solution hard-dissolving processing process for the valve disc neck, seeFigure 1 to 5 , Including the following steps:

[0053]1) Forming valve rod blank 4. Among them, the valve rod blank 4 is sequentially from the bottom to the umbrella portion 401, the tray 402, the rod portion 403, and the small end 404.

[0054]2) Place the umbrella portion 401 of the valve rod blank 4 is placed on the positioning clamp assembly 102 of the feed positioning device 1. Wherein, the feed positioning device 1 includes a telescopic rod 101 and a positioning clamp assembly 102. The positioning clamp assembly 102 is fixed to the upper end portion of the telescopic rod 101. Specifically, the positioning clamp assembly 102 is a positioning plate, and there is a threaded hole on the bottom surface of the positioning plate, and the end of the telescopic rod 101 has an external thread, and the positioning plate 102 is fixed to the end...

Embodiment 3

[0067]In this example, the main step is to Example 2, in step 1), the valve rod blank 4 uses austenite material forging, the valve rod blank 4 is formed, and the small end 404 and an umbrella of the valve rod blank 4 are formed. 401 Perform alloy reactors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com