Although the surface

hardness of electroplated

hard chromium is harder than that of

electroplated nickel layer, if it is specially treated, the hardness can reach 1000HV, but its existence uses Cr 6+ Due to the

high stress of the electroplated hard chrome coating, it cannot withstand long-term repeated

impact fatigue and stress

corrosion, which will cause the

electroplating chrome layer to break or wear, and instead cause easy-to-

cut marks and burrs

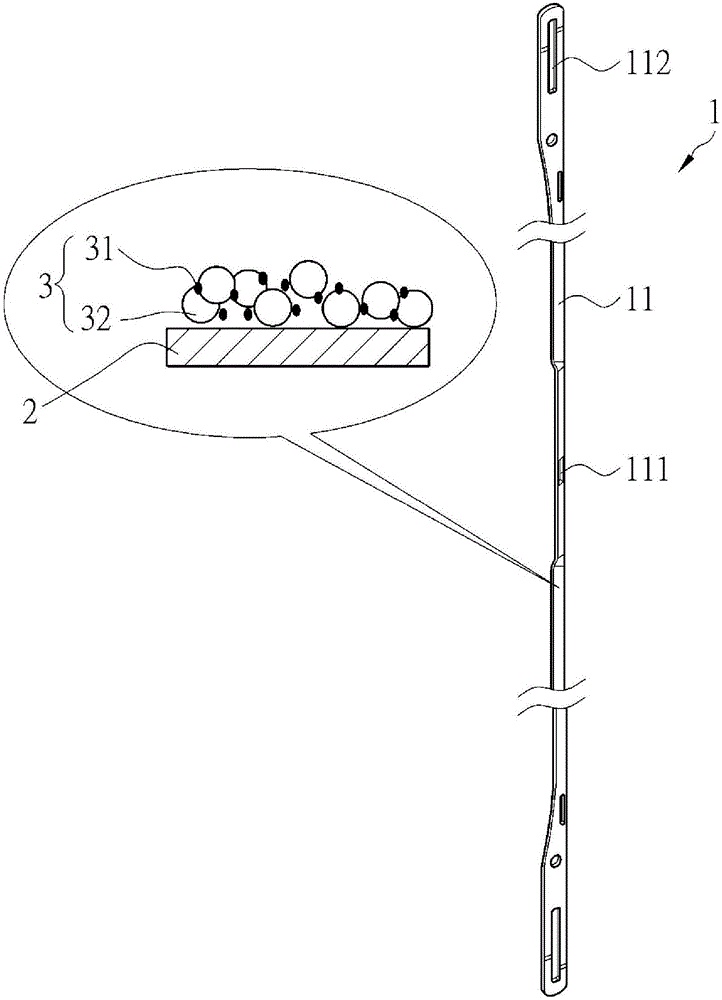

European Patent EP0485633, U.S. Patent US5511587, and

Chinese Patent Publication No. 201220262380.2 disclose the use of

nickel sulfate electroplating baths to combine

diamond-like (DLC),

silicon carbide (SiC), aluminum

oxide (Al 2 o 3 ), zirconia (ZrO 2 ),

chromium oxide (Cr 2 o 3 ) and other wear-resistant particles and

electroplated nickel are co-deposited on the special-shaped reed sheet or other weaving guide components, for example, the thickness is 5-20 μm, 1-10 μm, etc., reaching a surface hardness above 1000-2000HV and a

surface friction coefficient below 0.14; For example, European patent EP0550752 discloses coating DLC on

titanium carbide or other carbides, oxides, and electroplated

chromium to achieve

high wear resistance. However, the

alloy chemical composite layer of nanoparticles has poor adhesion and high production costs. problem, it is also difficult to popularize and use

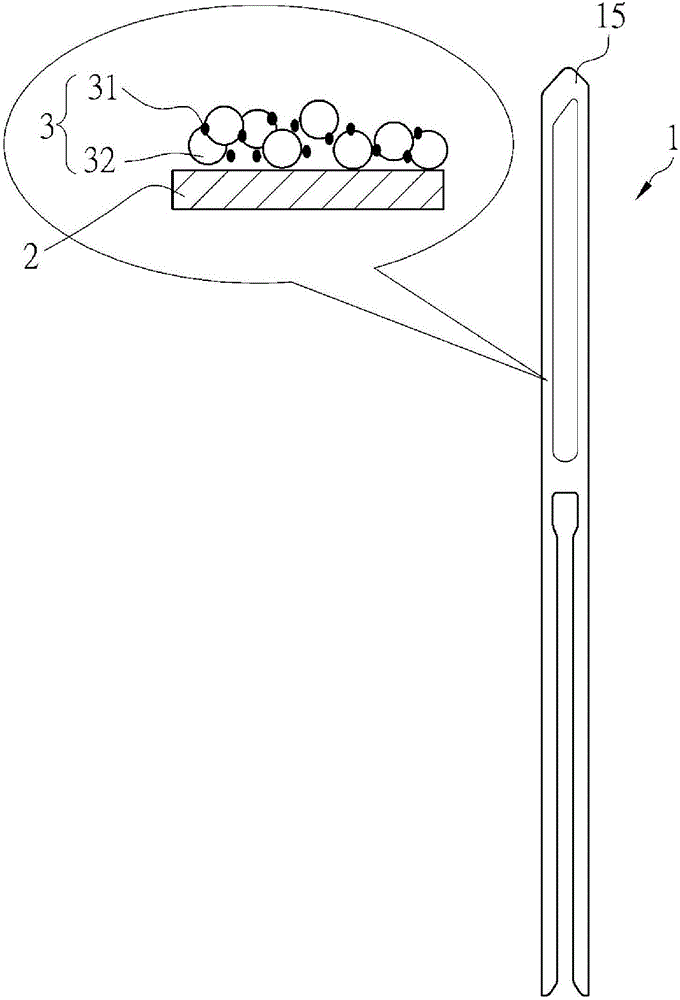

[0005] Although in recent years, breakthroughs have been made in

plastic materials, using

plastic materials to replace

metal plastic healds; plastic healds save material costs compared to metal healds, but it is difficult to solve the problem of

wear resistance.

Chinese Patent Publication No. CN201228305 is disclosed in Plastic Healds The part of the heald eye is made of ceramic heald eye, which can reduce the

friction coefficient between the warp yarn and the warp yarn by using the smooth and

high wear resistance of the ceramic; The weaving guide component of the yarn is difficult to implement in terms of

mass production or cost

When weaving high-strength textile fibers with plastic healds or plastic yarn guide components, there are still problems such as short service life, frequent shutdowns and replacements, poor weaving quality, and the difficulty of recycling waste plastic healds, causing huge damage to the environment, etc.

[0006]

Chromium metal materials,

chromium-

cobalt-

molybdenum alloy materials, chromium-

cobalt alloy materials, and chrome-iron alloy materials generally have good comprehensive mechanical properties, high hardness, strong

wear resistance, high

temperature resistance, and

corrosion resistance. They can be used in harsh industrial environments, China Patent CN103060617 A discloses high-temperature alloy

forging technology, but this kind of material generally has the characteristics of poor

toughness and easy

embrittlement, and it will be more expensive to directly use this kind of material to make the weaving guide assembly

If

plasma-assisted

chemical deposition, vapor deposition (CVD), high-energy micro-arc technology, high-temperature

carbonization, low-temperature

carbonization,

physical vapor deposition (PVD), the

sputtering method or vapor deposition method of US Patent No. 4925394, and the

diffusion of EP1878943

Chromium method, Taiwan Patent Publication No. TW201101565 using

powder bath method, Taiwan Patent TWI297365 and other prior technologies, disclosed that

chromium carbide powder material can be used to convert chromium metal, chromium-

cobalt-

molybdenum alloy to tools in the aforementioned manner (commonly known as dry method). , chrome-

cobalt alloy, chrome-iron alloy and other alloy materials are coated on the heald, although it can overcome the characteristics of poor

toughness and easy

embrittlement, it cannot solve the problems of high manufacturing cost and difficulty in

mass production

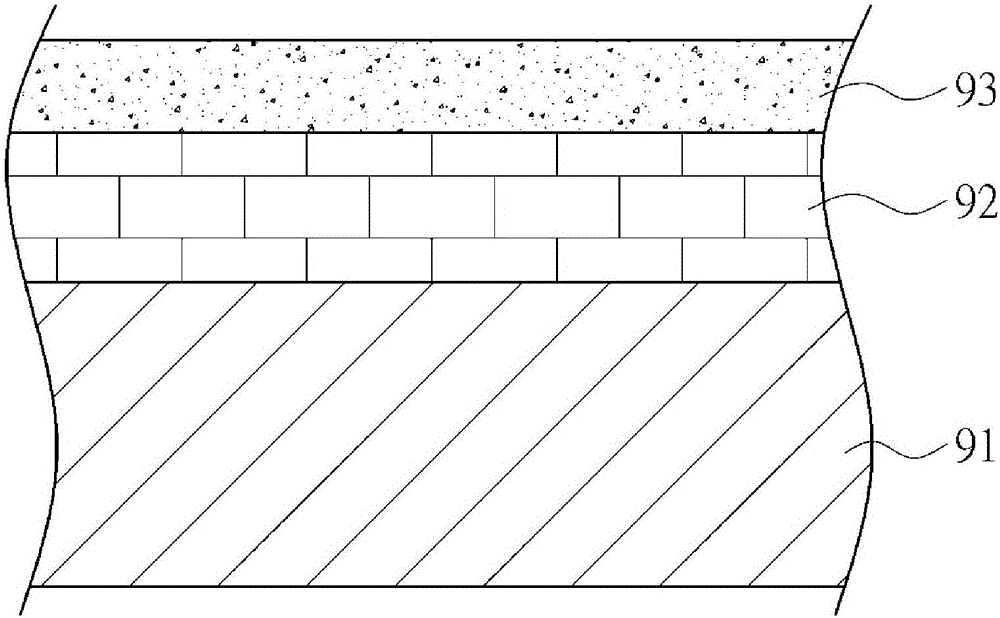

[0007] Metallized ceramics (metallic ceramic) is a ceramic-like structure co-construct formed by

doping non-metallic elements with metal elements, so that it has both metal and ceramic properties. For example, some co-constructs It has the hardness and good

corrosion resistance of ordinary ceramics, or has both metallic luster and

conductivity, or has both the color and luster of ceramics; Taiwan patents TWI441954, TWI441961, TWI533526 and

Chinese patent CN103726091 use electroplating methods (commonly known as Wet method) forms a metallized ceramic layer of

chromium carbide on the substrate. This metallized ceramic layer has hydrophobicity and good electrical

conductivity. If you want to increase the hardness, you need to use high temperature baking or burning with

flame; The components are light and thin, and cannot be baked at high temperature or burnt with flames to increase the hardness of the electroplating layer, otherwise the thin yarn guide components will lose their mechanical properties or warp, and the above-mentioned products have poor

surface flatness and a large

friction coefficient. Thin and soft weaving yarns will still have yarn scraping and cannot be used for weaving yarn guide components

[0008] In summary, the above-mentioned technologies have certain defects in solving high hardness, high hydrophobicity, anti-sticking,

high conductivity, etc., and it is impossible to obtain high hardness, wear resistance,

low friction, and heat conduction by using these technologies. The electroplated metallized ceramic layer with high coefficient to avoid heat accumulation is applied to the weaving guide assembly. Therefore, it is necessary to develop newer technologies and propose effective and specific improvement solutions

Login to View More

Login to View More  Login to View More

Login to View More