Transparent conductive optical sheet having high invisibility of pattern

A transparent conductive, optical sheet technology, applied in optics, optical components, electrical digital data processing, etc., can solve problems such as trouble, poor surface resistance, and reduced effect of film dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 20

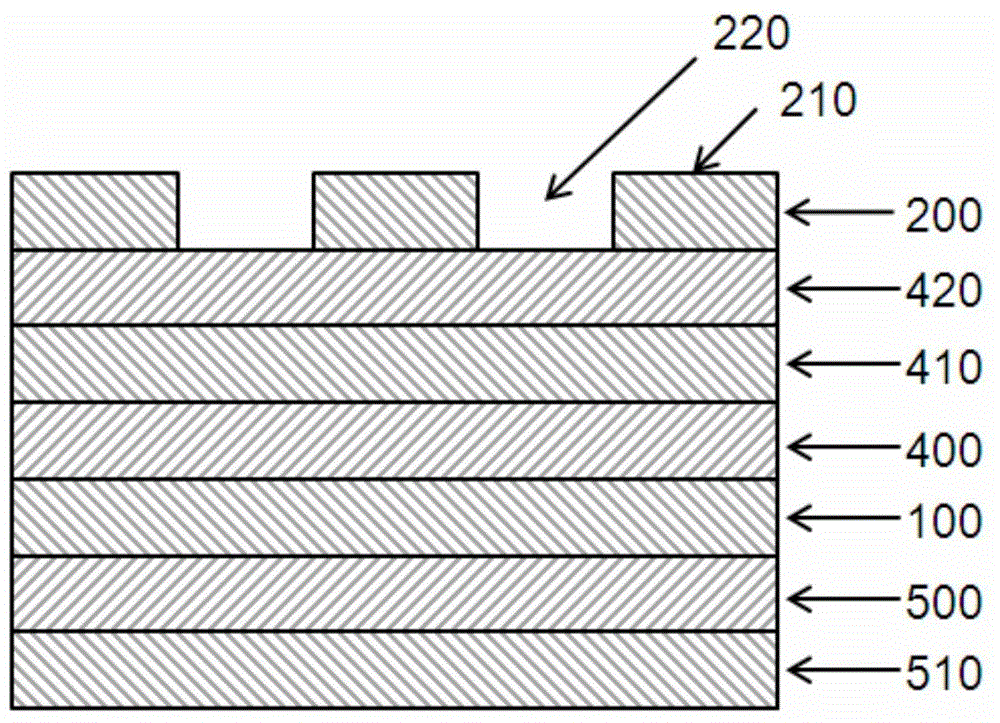

[0147] Examples 1 to 20: Fabrication of Transparent Conductive Optical Sheets with Index Matching Layers

[0148] Step 1: Prepare the transparent base layer

[0149] A PET transparent substrate having a refractive index of 1.63 to 1.67 in a wavelength of 550 nm and a thickness of 50 μm was used.

[0150] Step 2: Forming the first index matching layer

[0151] 5.5 parts by weight of thermosetting acrylic resin (A811, Ai Jing Chemical Co.), 0.3 parts by weight of polyisocyanate curing agent (DN980S, Ai Jing Chemical Company), 47.1 parts by weight of xylene (xylene) for dilution and After 47.1 parts by weight of butyl acetate are mixed, 50 to 80 parts by weight of zirconia (ZrO 2 , JGC Corporation) for further mixing. Then, the obtained mixed solution is wet-coated on the transparent base layer, and then dried and thermally cured, so as to form the first layer having a refractive index in the range of 1.56-1.66 at a wavelength of 550 nm and a thickness in the range of 20-100 n...

Embodiment 11 to 35

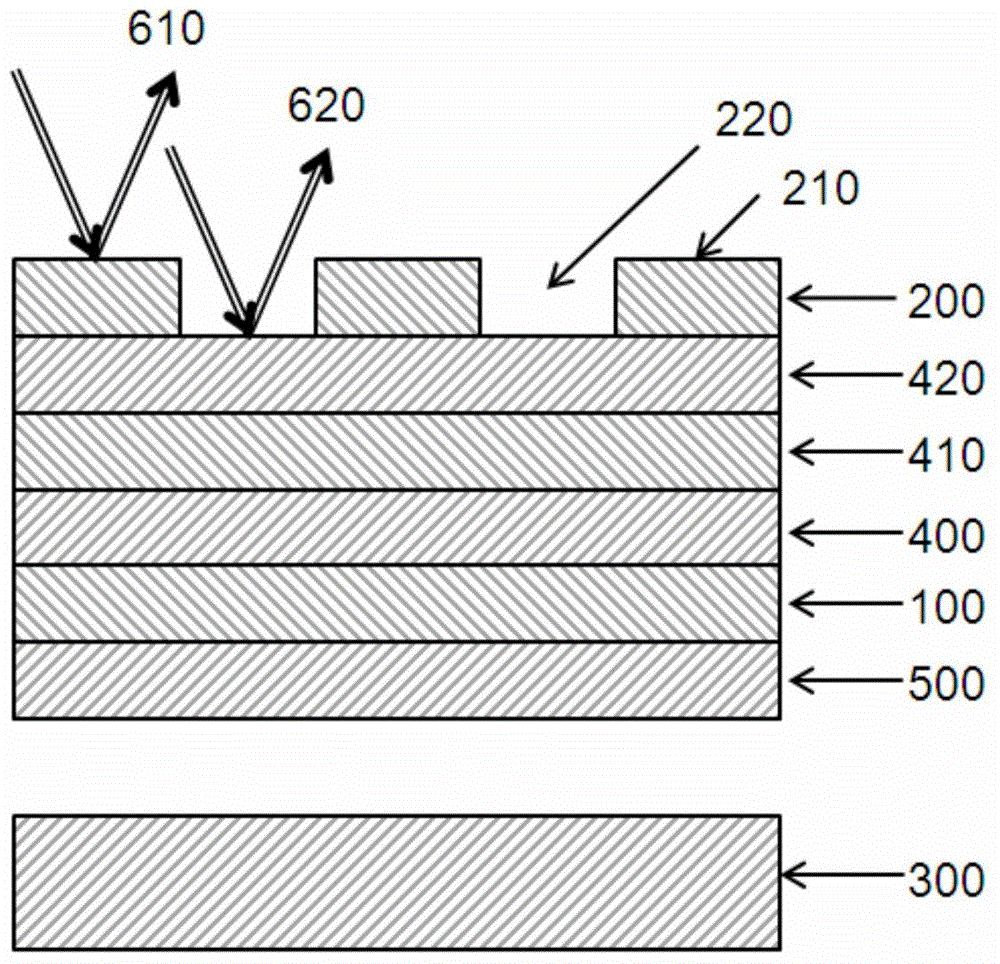

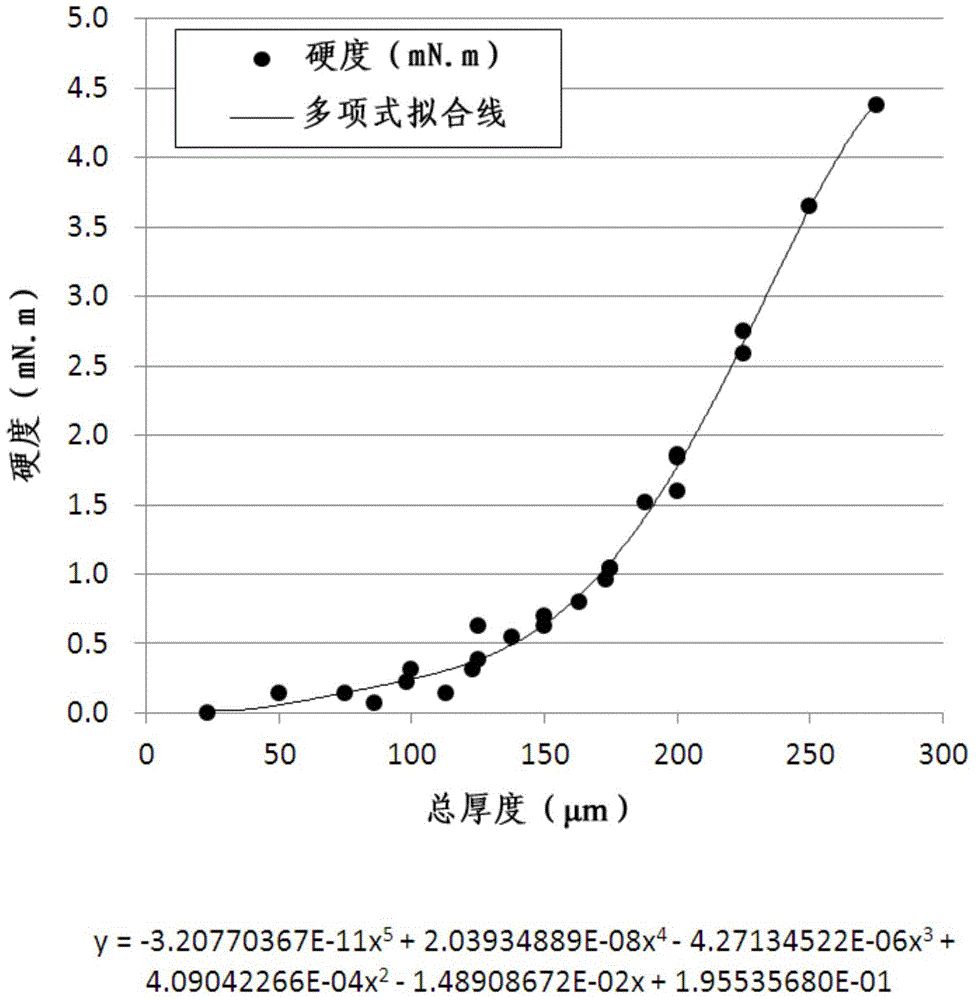

[0190] Examples 11 to 35: Transparent conductive optical sheet with hardness-enhancing film

[0191] The transparent conductive optical sheet was produced in the same steps as in Example 1, and the total thickness was adjusted to 23-125 μm.

[0192] Moreover, a hardness-enhancing film having a base film layer with a thickness of 38 to 125 μm and an adhesive functional layer with a thickness of 20 to 50 μm formed on one of its surfaces was prepared. At this time, the base film layer was made of a PET transparent substrate. material, the adhesive functional layer includes 100 parts by weight of acrylic polymer resin and 0.001-10 parts by weight of isocyanate crosslinking agent (polyfunctional isocyanate compound).

[0193] Then, a transparent conductive optical sheet having a hardness-improving film is manufactured by pasting the adhesive functional layer of the hardness-improving film on the transparent base layer of the optical sheet.

[0194] However, for comparison, some tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com