A countercurrent induced draft feed dryer

A dryer and feed technology, which is applied in the direction of static material dryer, granular material drying, local mixing dryer, etc., can solve the problems of large-scale machinery not in line with economic benefits, farmers' unaffordable price, and small scale of feed use. Achieve the effect of reducing labor intensity, simple structure and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

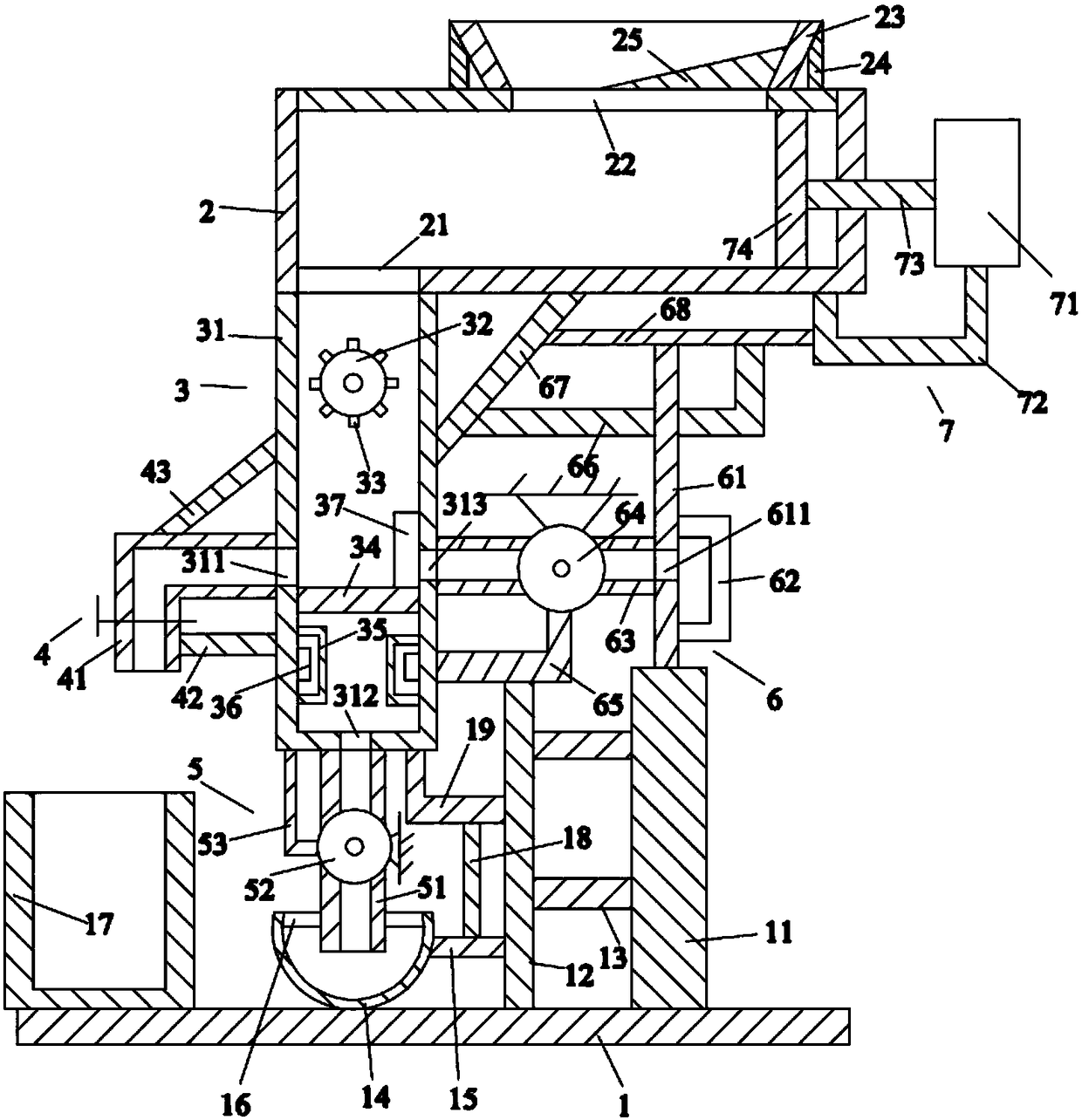

[0019] Such as figure 1 As shown, the countercurrent induced draft feed dryer of the present invention includes a base plate 1, a frame body 2 located above the base plate 1, a drying device 3 located below the frame body 2, and a discharge device located on the left side of the drying device 3 4. An air extraction device 5 located below the drying device 3 , an air blowing device 6 located on the right side of the drying device 3 , and a material pushing device 7 arranged on the frame body 2 .

[0020] Such as figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is placed horizontally. The base plate 1 is provided with a first support rod 11 above it and a second support rod 12 on the left side of the first support rod 11. , the first cross bar 13 on the right side of the second support bar 12, the purification frame 14 on the left side of the second support bar 12, the second cross bar 15 on the right side of the purification frame 14, accommodated in The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com