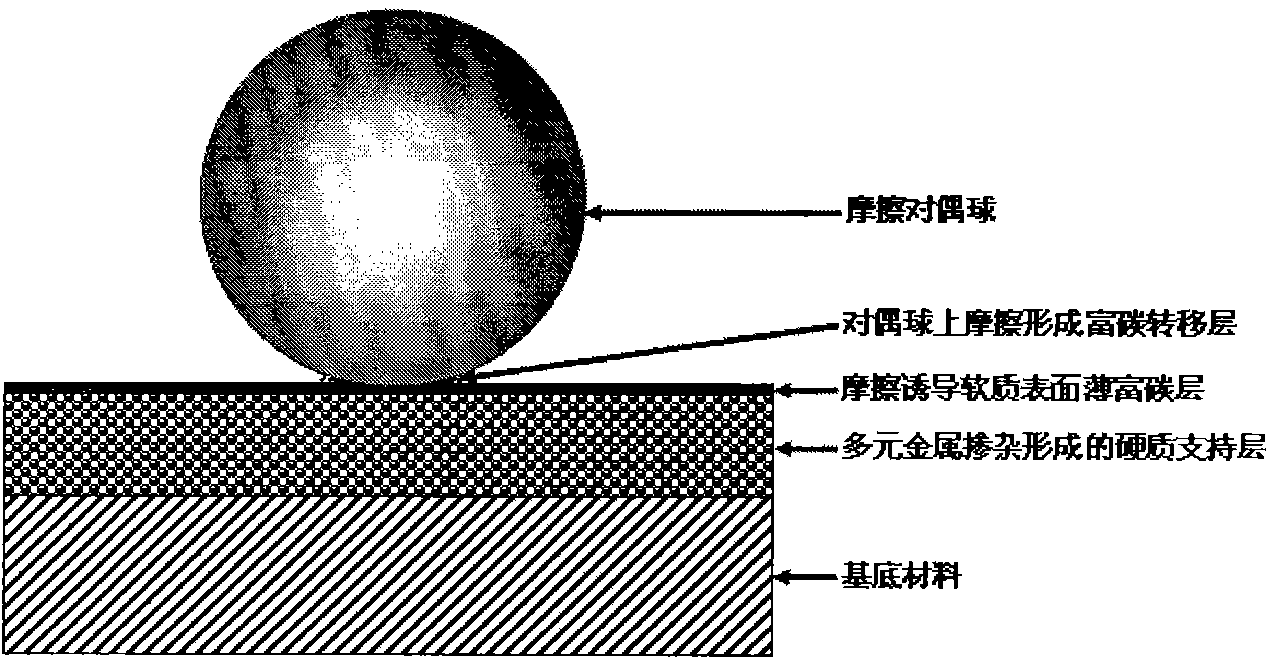

Method for preparing multi-element doped carbon-based nano composite film integrating functions of antiwear and lubrication

A carbon-based nano-composite thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of increased wear and tear of diamond-like carbon film, increased brittleness of diamond-like carbon film, and increased diamond-like carbon film. Hardness reduction and other problems, to achieve the effect of promoting carbon phase separation, excellent wear resistance, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Anti-wear and lubrication integrated multivariate doped nc-(Ti, Al)C / a-C carbon-based nanocomposite lubricating film, which is sequentially composed of bearing steel substrate, Ti bonding layer with a thickness of 0.5 microns and multi-doped with a thickness of 2.4 microns The surface layer of nc-(Ti, Al)C / a-C carbon-based composite film.

[0022] The multi-component doped nc-(Ti, Al)C / a-C carbon-based nanocomposite film preparation process is carried out according to the following steps: (1) Plasma sputtering cleans the substrate, and the substrate is placed in a magnetron sputtering vapor deposition system for Argon plasma sputtering cleaning, the flow rate of argon gas is 100sccm, the bias voltage is -1000V, and the processing time is 30min; The power of the intermediate frequency power supply is 700W, the bias voltage applied to the substrate is -500V, and the processing time is 25min; (3) Magnetron sputtering deposits multi-component doped nc-(Ti,Al)C / a-C carbon-ba...

Embodiment 2

[0024] Anti-wear and lubrication integrated multivariate doped nc-(W, Al)C / a-C carbon-based nanocomposite lubricating film, which is sequentially composed of bearing steel substrate, bottom Ti bonding layer with a thickness of 0.5 microns and multi-doped multi-doped with a thickness of 2.7 microns The surface layer of hetero nc-(W, Al)C / a-C carbon-based composite film.

[0025] The preparation process of multi-component doped nc-(W, Al)C / a-C carbon-based composite film is carried out according to the following steps: (1) Plasma sputtering cleans the substrate, puts the substrate in a magnetron sputtering vapor deposition system, and conducts argon Plasma sputtering cleaning, the flow rate of argon gas is 100sccm, the bias voltage is -1000V, and the processing time is 30min; (2) Ti bonding layer is deposited by magnetron sputtering, the Ti target is the cathode, the working gas is argon, and the intermediate frequency is controlled The power supply is 700W, the bias voltage app...

Embodiment 3

[0027]Anti-wear and lubrication integrated multivariate doped nc-(Mo, Al)C / a-C carbon-based nanocomposite lubricating film, which is sequentially composed of a bearing steel substrate, a bottom layer Ti adhesive layer with a thickness of 0.5 microns and a multi-component doped layer with a thickness of 2.05 microns The surface layer of hetero nc-(Mo, Al)C / a-C carbon-based nanocomposite film.

[0028] The preparation process of multiple doped nc-(Mo, Al)C / a-C carbon-based nanocomposite films is carried out according to the following steps:

[0029] (1) Plasma sputtering to clean the substrate, place the substrate in a magnetron sputtering vapor deposition system, and perform argon plasma sputtering cleaning, the argon gas flow rate is 100 sccm, the bias voltage is -1000V, and the processing time is 30 minutes; (2) Ti bonding layer deposited by magnetron sputtering, the Ti target is the cathode, the working gas is argon, the power of the intermediate frequency power supply is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com