Plunger Pump, Plunger, and Method of Manufacturing Plunger Pump

a technology of plunger pump and plunger, which is applied in the direction of positive displacement liquid engine, piston pump, application, etc., can solve the problems of hollow plungers deflecting diametrically under loads, large diameter and/or longer stroke plungers with solid construction are often unwieldy to handle during routine maintenance operations, and the gap clearance may be small and have a detrimental effect on the life of packing, etc., to achieve the effect of improving the stiffness of the plunger and improving the stiffness of the plung

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In the following detailed description, numerous specific details may be set forth in order to provide a thorough understanding of the disclosed embodiments. However, it is to be understood that other embodiments of the invention may be practiced without incorporating some or all of the specific details that are a part of these disclosed embodiments. In other instances, well-known features or processes may not be described in detail in the disclosed embodiments so as not to unnecessarily obscure the disclosure. In addition, like or identical reference numerals may be used to identify common or similar elements between the embodiments.

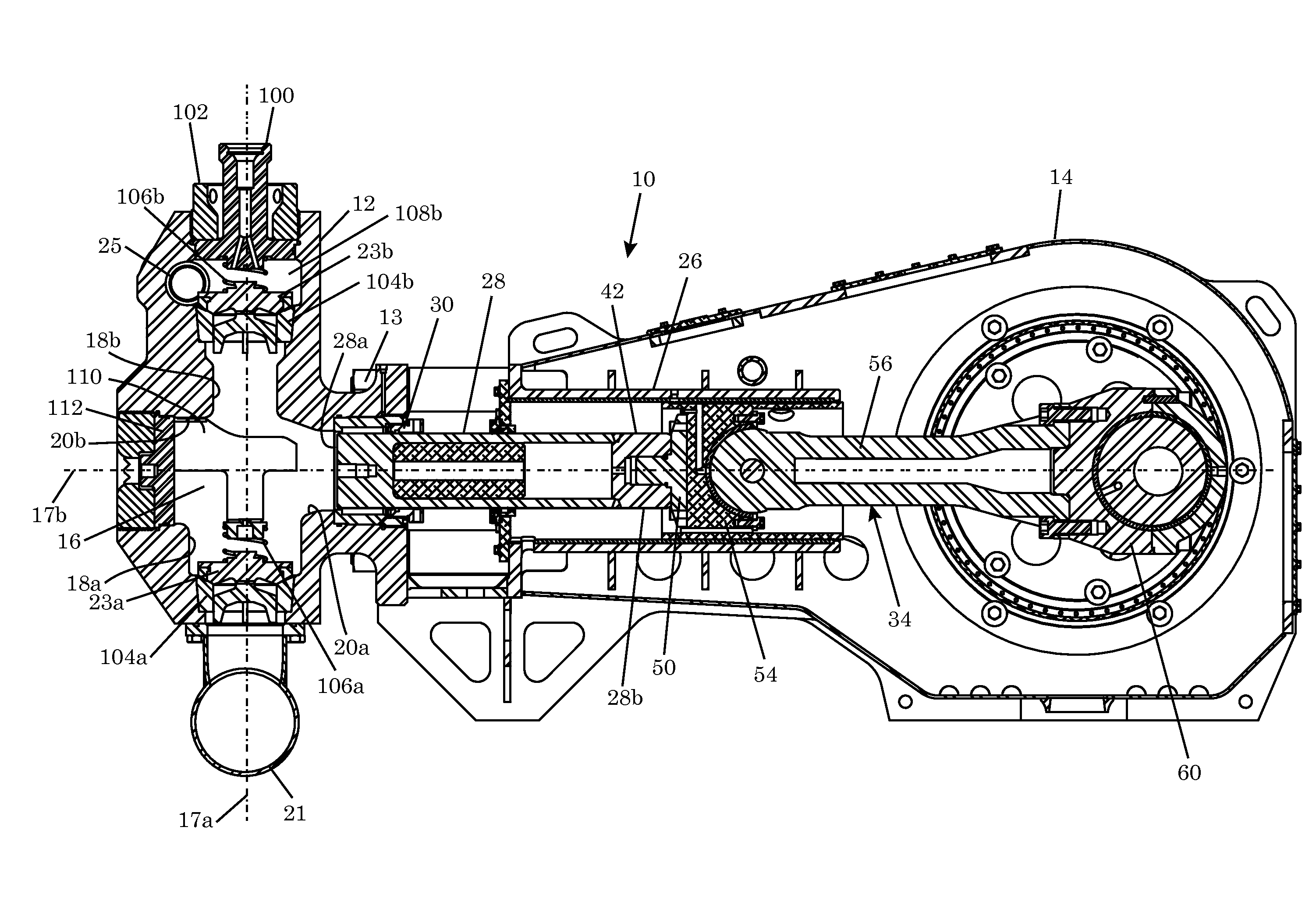

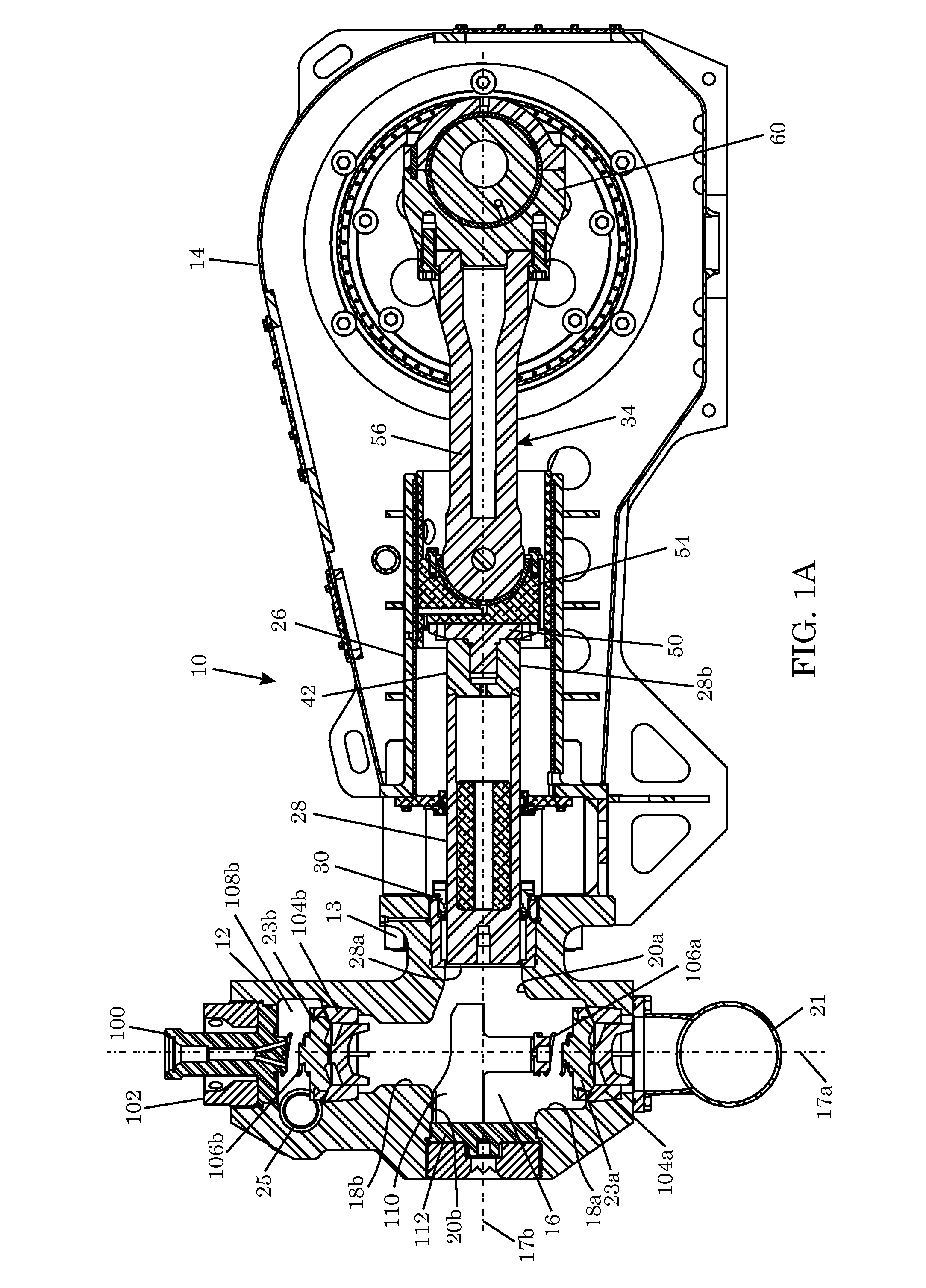

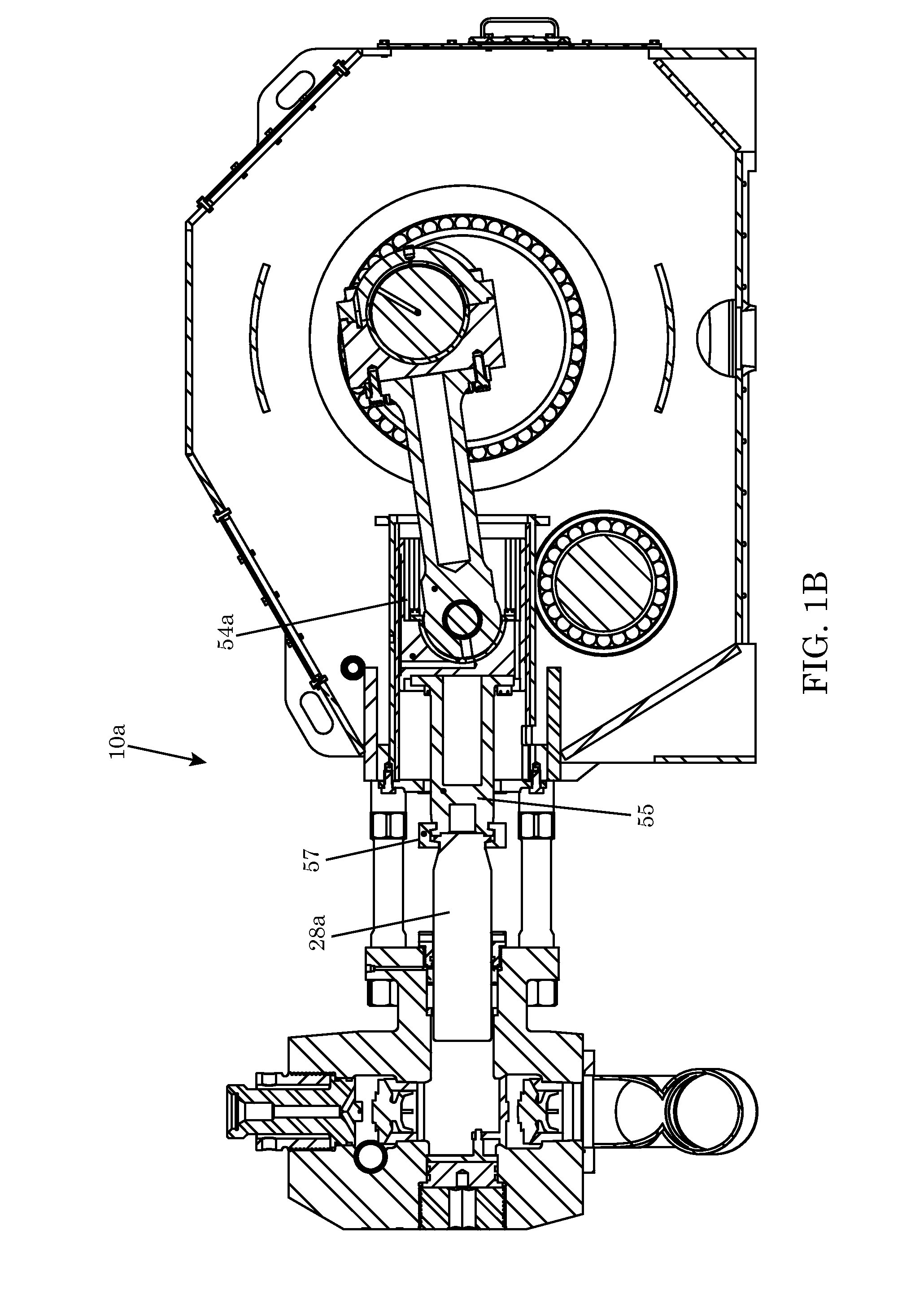

[0024]FIG. 1A is an illustrative embodiment of a plunger pump 10 having a pump fluid end 12 coupled to a pump power end 14 via stay rods 13. The pump fluid end 12 includes a fluid chamber 16. The pump fluid end 12 further includes a suction bore 18a, a discharge bore 18b, a plunger bore 20a, and an access bore 20b, all of which intersect with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| localized stress concentrations | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com