A method for positioning the formwork arch trolley in tunnel construction by ruler

A technology of tunnel construction and positioning method, which is applied in the direction of measuring devices, instruments, surveying and navigation, etc., which can solve the problems of difficulty in guaranteeing the construction quality of buttress forming, difficult process control and control, and balance errors, etc., so as to achieve easy observation and control , low cost of measures, and great versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

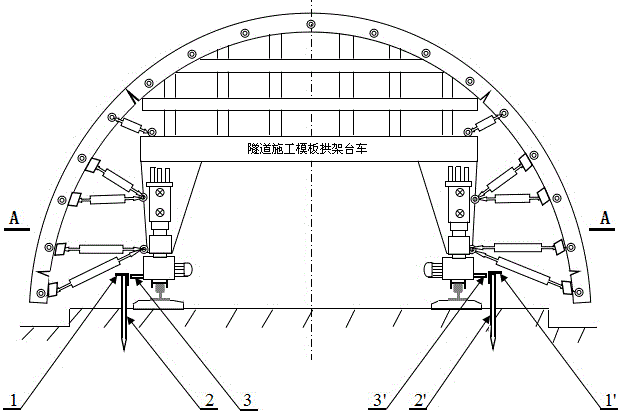

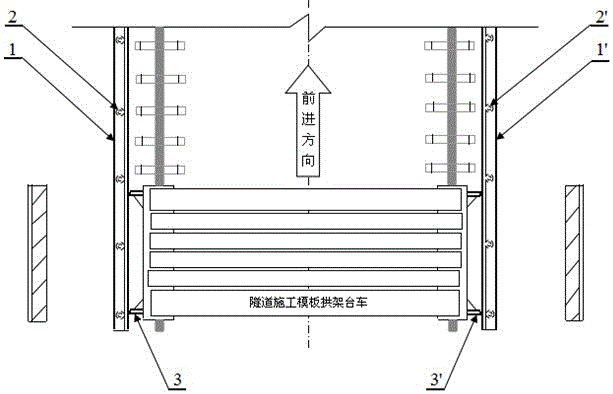

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] A method for positioning a formwork arch trolley in tunnel construction by a ruler includes the following steps:

[0019] 1) Determine that the traveling mechanism that needs to be positioned by the ruler is the tunnel construction formwork arch trolley;

[0020] 2) In the forward direction of the formwork arch trolley, that is, in the forward direction of the excavation construction tunnel, according to the technological requirements, parallel and symmetrical to the center line of the excavation construction tunnel, determine the parallel position line that needs to be installed with the ruler, and lay out several on the determined position line. Steel piles, use angle steel to fix the steel piles on each side to form a positioning guide for the tunnel construction formwork arch trolley; install calibration contact points on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com