Three-in-one acidification unblocking agent for oil well unblocking and application method thereof

A three-in-one, plugging agent technology, applied in the direction of chemical instruments and methods, drilling compositions, earthwork drilling and mining, etc., can solve the problems of high strength of on-site liquid mixing, environmental pollution, occupation of construction sites, etc., and achieve rapid acidification The effect of unblocking on-site construction, reducing the risk of environmental pollution, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A three-in-one acidifying plugging remover for oil well plugging removal, including 250 parts by weight of a mixture of acetic acid and sulfamic acid (the mass ratio between acetic acid and sulfamic acid: 3:4), sodium polyepoxysuccinate And 150 parts by weight of sodium polyacrylate mixture (mass ratio between sodium polyepoxysuccinate and sodium polyacrylate: 2:5), 50 parts by weight of polyquaternium salt, 80 parts by weight of cinnamaldehyde and mercaptobenzothiazole ( The mass ratio between cinnamaldehyde and mercaptobenzothiazole is: 3:2), polyoxyethylene polyoxypropylene stearyl ether and polyoxyethylene-polyoxypropylene block copolymer 30 parts by weight (polyoxyethylene polyoxypropylene The mass ratio between propylene stearyl ether and polyoxyethylene-polyoxypropylene block copolymer is: 1:2), hydrogen fluoride 50 weight parts, fatty acid methyl ester ethoxylate 40 weight parts, ethylene glycol butyl ether 60 parts by weight, 290 parts by weight of clear water;...

no. 2 example

[0042] In this example, the conventional performance index of a three-in-one acidizing plugging remover used for plugging removal of oil wells is explained in detail through laboratory experimental data.

[0043] A three-in-one acidification plugging removal agent for oil well plugging removal of the present invention has the main functions of pre-acid, main acid and post-acid in conventional acidification, its use concentration is 33%, and the dissolution rate of bentonite in 4 hours is 44.8 %, the dissolution rate of sandstone rock powder in 4 hours is 24.3%, and the corrosion rate of N80 coupons at 90°C is 1.05g / (m 2 .h) (industry standard level 1 is ≤5 g / (m 2 .h)), the residual acid surface tension is 26.2mN / m (the industry standard is ≤32 mN / m), the clay stability rate is 85%, the iron ion stability percentage is 81.2%, and the acid slag resistance rate is 99.8%.

no. 3 example

[0045] This example uses laboratory experimental data to describe in detail the core plugging removal laboratory simulation experiment of a three-in-one acidification plugging removal agent for oil well plugging removal.

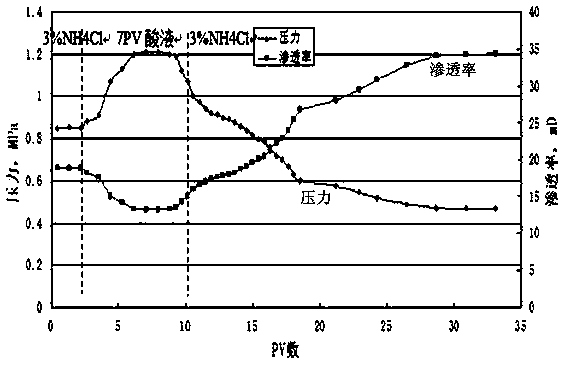

[0046] Contaminated cores from the well bottom of Wei 2 Oilfield, Jiangsu Oilfield, Sinopec were used. The length of the core is 5.48cm, the diameter of the core is 2.54cm, the porosity is 12.9%, and the permeability of the core is 18.8mD. To simulate the situation of the Wei 2 oil reservoir, at a temperature of 80°C, the core flow experiment device is used to conduct the plugging removal experiment of oil well acidification and plugging removal agent, according to Example 1 Configure the original solution of plugging solution, and the injection method is "3% ammonium chloride solution (to test the initial permeability) → 30% acidified plugging solution → 3% ammonium chloride solution".

[0047] Experimental results such as figure 1 , after injecting the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com