A correction method for tunnel construction arch formwork

A technology for tunnel construction and arch frame, which is applied to tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of difficult to guarantee the construction quality of buttress forming, time-consuming and laborious calibration of a single jacking cylinder, and difficult process control and control. Simple process and tooling, low cost of measures, and the effect of process control and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] A kind of tunnel construction arch template correction method of the present invention comprises the following steps:

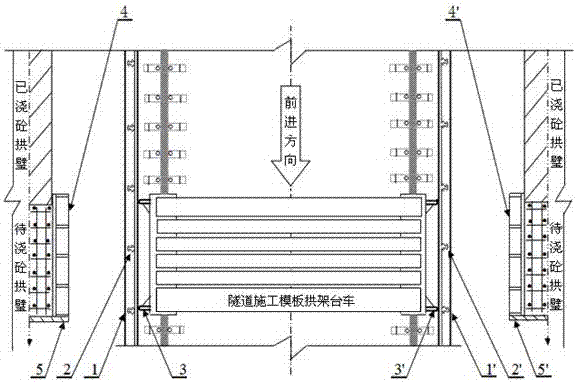

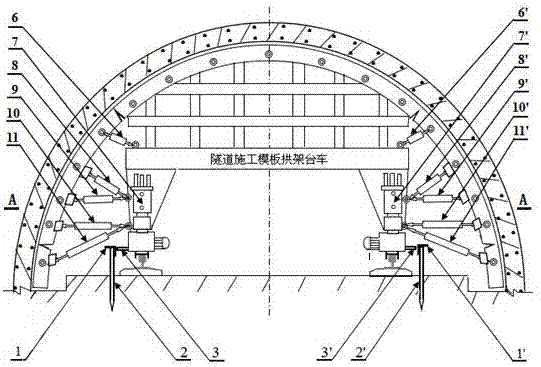

[0019] 1) Carry out excavation according to the tunnel construction technology, and prepare qualified arch formwork and arch trolley for tunnel construction, and assemble them completely;

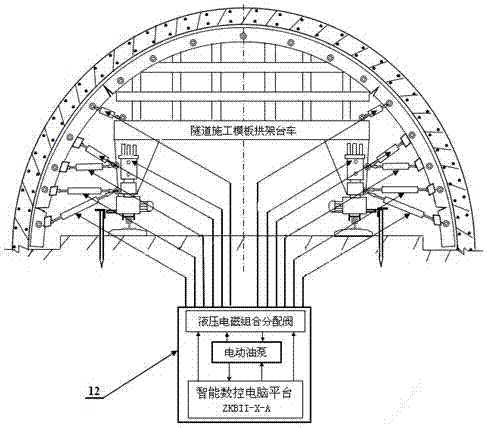

[0020] 2) According to the tunnel construction process requirements, the assembled arch trolley is moved and fixed in the direction of the tunnel; The high-pressure oil pipes are respectively connected to each hydraulic jacking cylinder fixedly installed on the arch trolley, and the pump station provides hydraulic power to each hydraulic jacking cylinder through the high-pressure oil pipe; The sensors are respectively connected with the intelligent numerical control computer platform for signal transmission, such as the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com