Prefabricated ultra-deep foundation pit ramp system and its construction method

A prefabricated, deep foundation pit technology, applied in infrastructure engineering, excavation, on-site preparation of building components, etc., can solve the problems of enlarging the narrow and long foundation pit, increasing the cost of the support system, etc., and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

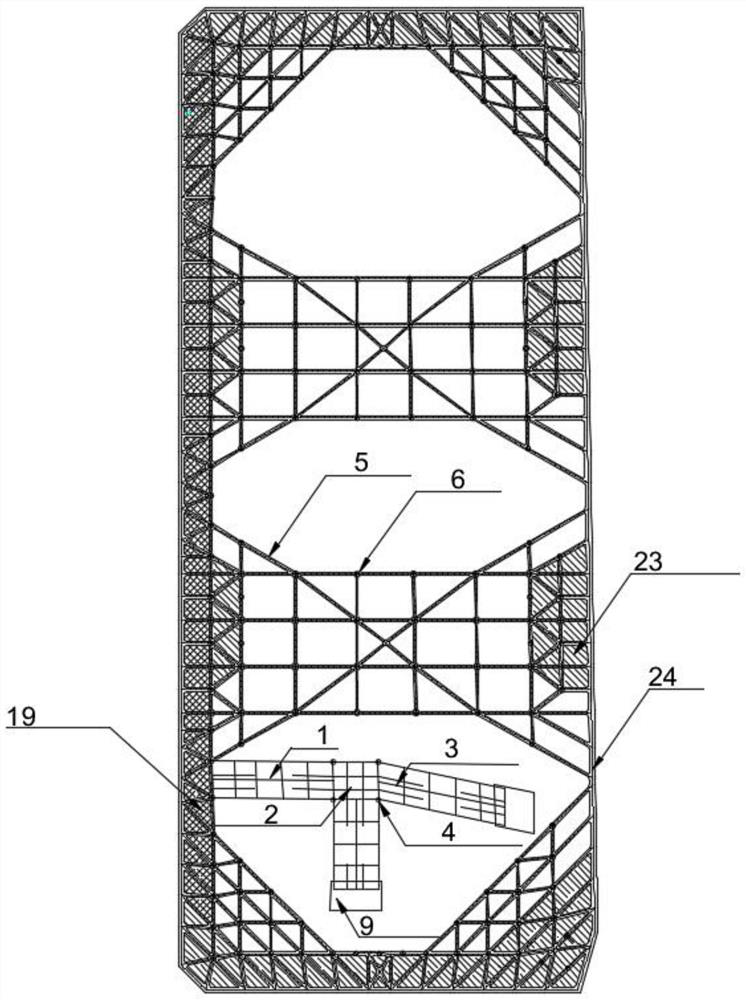

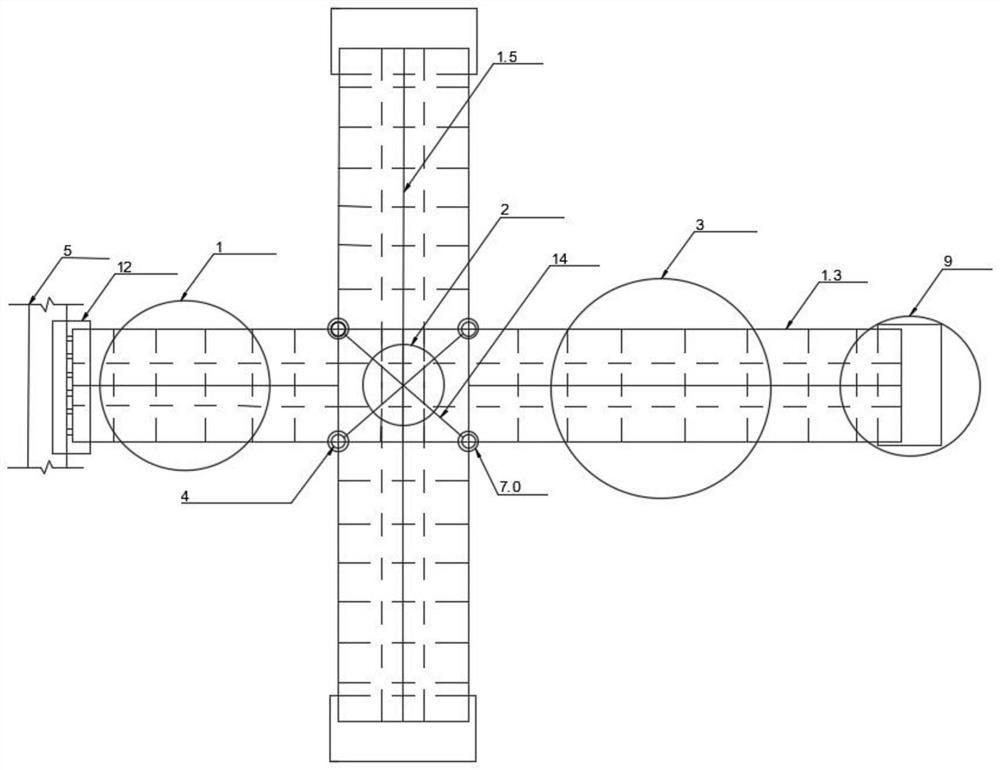

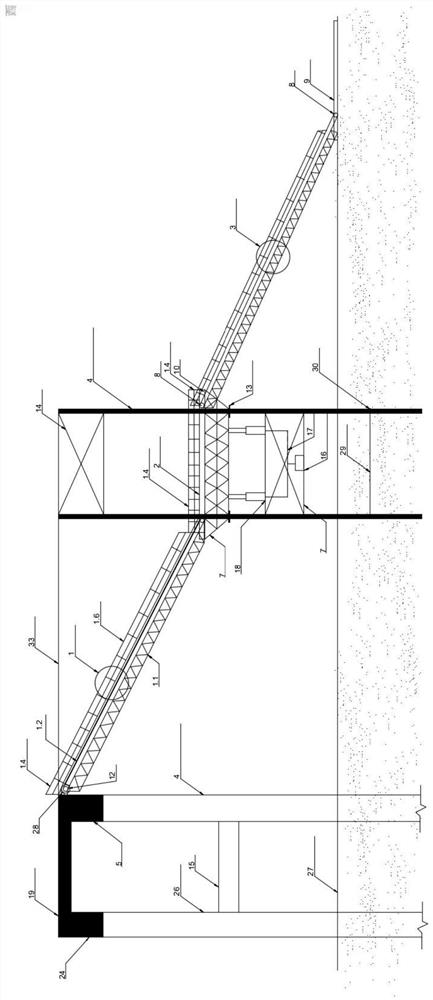

[0032]As shown in the figure, the prefabricated ultra-deep foundation pit ramp system includes a ramp structure and a vertical support structure; the ramp structure includes a primary ramp 1, a transition platform 2, and a secondary ramp 3; the vertical support structure includes Four concrete-filled steel pipe columns 4, supporting beams 5, column piles 6 and several supporting trusses 7; The rod-type jack propulsion system is used to control the lifting of the transition platform 1, thereby adjusting the slope of the ramp structure; the support truss 7 is used as the support structure of the transition platform 2, and a panel is set on the top surface of the support truss 7 for vehicles to drive; the first grade slope Road 1 is composed of Bailey beam 1.1, steel backing plate 1.2, waterproof material, protective material, prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com