Post-cast strip wall formwork structure and construction method for advanced water stop of outer wall post-cast strip

A construction method and post-casting belt technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve the problem of basement structure and foundation pit support. Due to the short distance, the difficulty of brick-laying and closed construction, and the increase of cost, the effect of simple structure, short welding time and reduced cost of measures is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

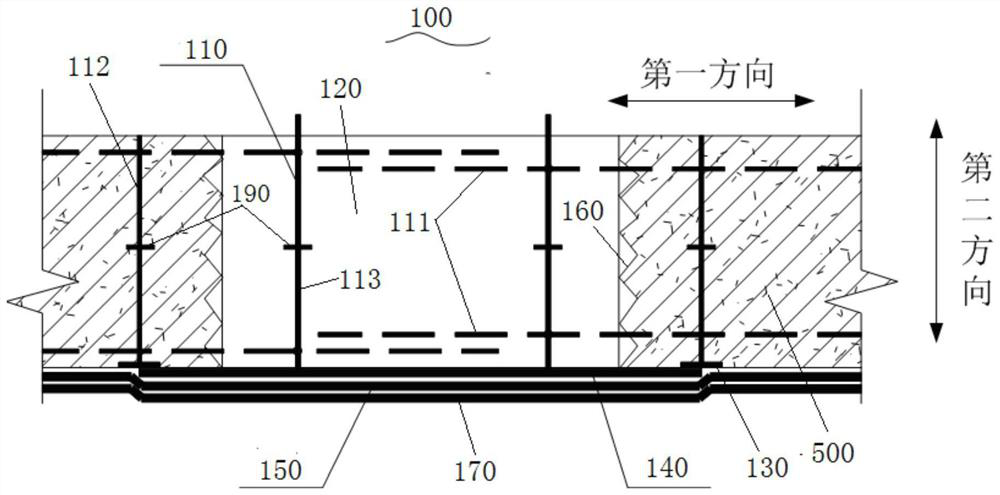

[0066] As an embodiment, the waterproof layer 150 includes a polyurethane coating waterproof layer 151 and a self-adhesive membrane waterproof layer 152, and step S8 includes:

[0067] S81, the polyurethane coating waterproof layer 151 is covered on the outside of the concrete 500 and the steel cover plate 140,

[0068] S82, the self-adhesive membrane waterproof layer 152 is covered on the polyurethane coating film waterproof layer 151.

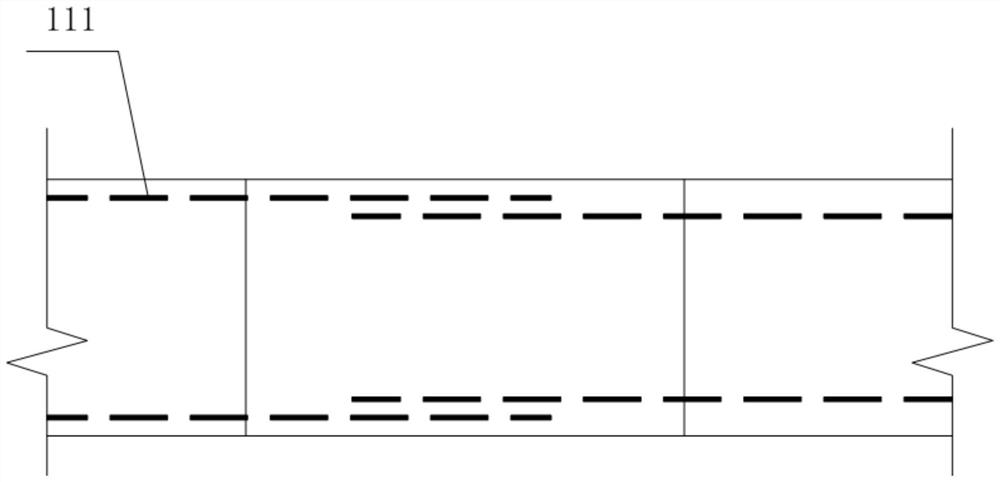

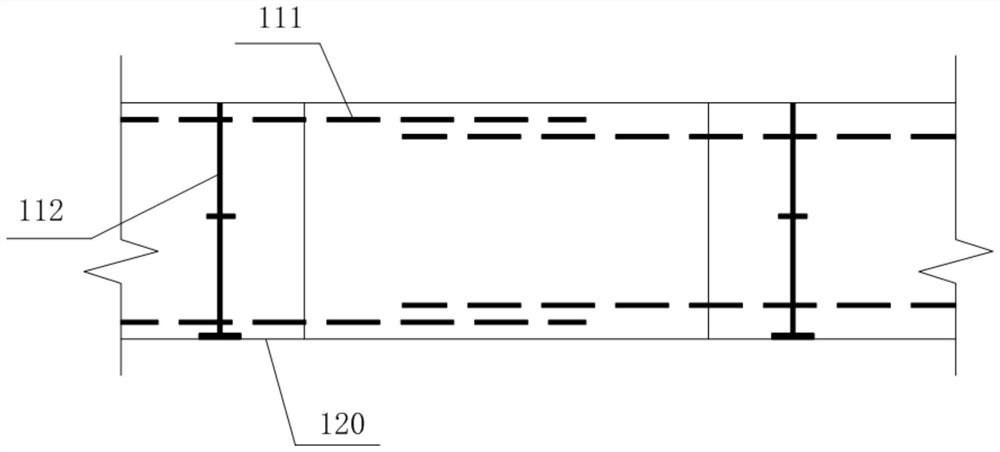

[0069] In the construction method of the above-mentioned outer wall post-casting with advanced water-stop, the pre-embedded steel plate 130 and the first water-stop screw 112 can be made in advance, and when the outer wall steel bars 111 are bound, the first water-stop screw 112 is welded to the outer shear wall steel bars. The upper part of 111 ensures that the concrete is not deviated during the concrete pouring process. The steel cover plate 140 and the embedded steel plate 130 are fully welded to ensure no water seepage. In this way, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com