Fire flooding producing well layering gas channeling plugging technology

A technology for producing wells and gas channeling, which is applied in the directions of sealing/isolation, wellbore/well components, and production fluids, etc. It can solve the problems of unsatisfactory sealing effect, complicated construction procedures, and long construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

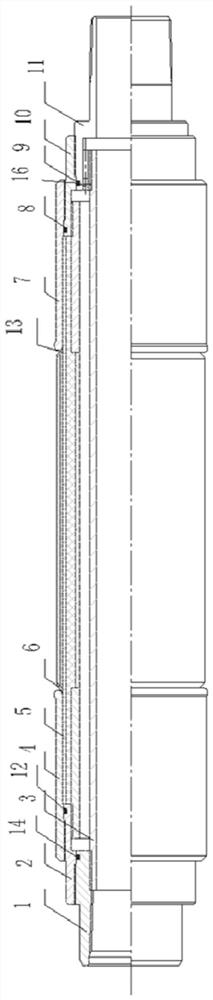

[0089] This embodiment provides an expandable small-diameter K344 packer, and its structure diagram is as follows figure 1 Shown from figure 1 It can be seen that the expandable small diameter K344 packer includes:

[0090] Upper joint 1, upper connecting sleeve 2, central tube 3, upper outer shield 4, sealing rubber cylinder 5, first stop ring 6, second stop ring 13, lower outer shield 7, first rubber ring 12, The second rubber ring 8, the first valve cover, the second valve cover 9, the lower connecting sleeve 10, the lower joint 11, the third rubber ring 14, the fourth rubber ring 15;

[0091] The upper joint 1 is connected with the upper external thread of the center tube 3 through its lower internal thread; the upper joint 1 is connected with the internal thread of the upper connecting sleeve 2 through its lower external thread; the upper outer shield 4 is connected with the external thread of the upper connecting sleeve 2 through the internal thread of the upper end;

[0092] ...

Embodiment 2

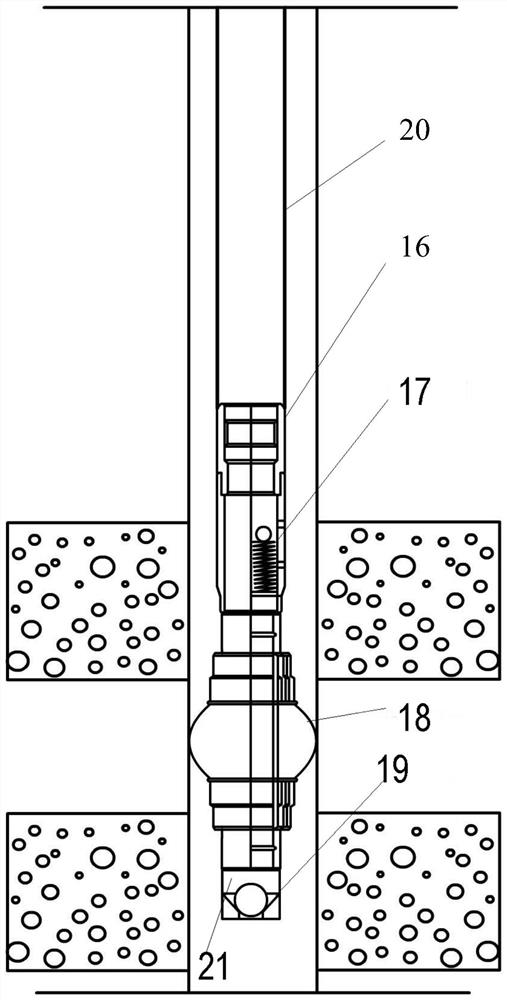

[0109] This embodiment provides a stratified gas channeling plugging pipe string for a fire drive production well. figure 2 Shown from figure 2 It can be seen that the stratified gas channeling plugging string of the fire drive production well includes:

[0110] Pressure relief valve 16, throttle valve 17, the expandable small-diameter K344 packer 18 and check valve 19 provided in Example 1;

[0111] The pressure relief valve 16 and the throttle valve 17 are sequentially installed on the first oil pipe 20 from top to bottom;

[0112] The upper joint 1 of the expandable small diameter K344 packer 18 is connected to the first oil pipe 20 through its upper internal thread; the lower joint 11 of the expandable small diameter K344 packer 18 is connected to the second oil pipe through its lower internal thread The oil pipe 21 is connected;

[0113] The check valve 19 is connected to the bottom end of the second oil pipe 21 at the lower part of the expandable small-diameter K344 packer 1...

Embodiment 3

[0115] This embodiment provides a stratified gas channeling plugging process for fire-flooding production wells, wherein the stratified gas channeling plugging process for fire-flooding production wells utilizes the stratified gas channeling sealing process for fire-flooding production wells provided in Example 2. To plug the pipe string, the process includes the following steps:

[0116] The stratified gas channeling plugging string of the fire-flooded production well provided in Example 2 of the present invention is lowered to the designed position. After the wellhead is installed, the ground uses a cement truck to inject water into the tubing to suppress the pressure. Bottom, the oil jacket forms a pressure difference, and the sealant cylinder of the expandable small-diameter K344 packer expands to seal the annulus of the oil jacket against the casing wall to complete setting.

[0117] Inject a certain amount (200-300m) from the tubing into the oil layer 3 ), the gel composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com