Method for acquiring maximum seepage flow resistance gradient of oil-water two-phase flow of compact low-permeability oil reservoir

A seepage resistance and acquisition method technology is applied in the field of obtaining the maximum seepage resistance gradient of oil-water two-phase flow in tight low-permeability reservoirs, which can solve the problems of non-injection, non-production, and affecting the effective development of low-permeability reservoirs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

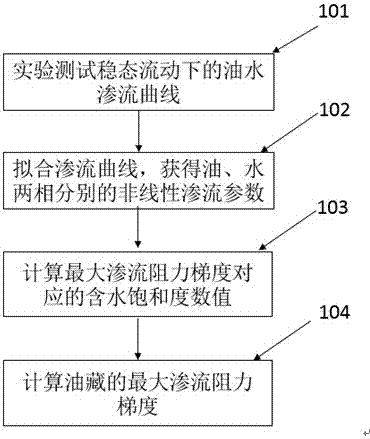

[0022] Such as figure 1 as shown, figure 1 It is a flow chart of the method for obtaining the maximum seepage resistance gradient of oil-water two-phase flow in tight low-permeability reservoirs of the present invention.

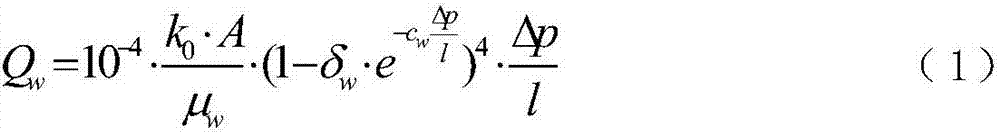

[0023] In step 101, the core is dried and saturated with deionized water, and under a certain fixed oil-water volume ratio, different displacement pressures are used to inject until a steady flow is achieved, and the multi-functional core displacement device is used to measure Steady-state pressure gradient-flow relationship, respectively record the seepage velocity of oil and water passing through low-permeability cores under different displacement pressure differences, draw the relationship curve between oil and water displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com