Long-span multi-section combined truss roof structural system and construction method thereof

A multi-section, large-span technology, applied in truss structures, girders, trusses, etc., can solve the problems of insufficient rigidity of pipe trusses, inaccurate installation positions, unstable stress structures, etc., to achieve performance optimization and structural optimization, The effect of optimizing the amount of steel used in the structure and improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

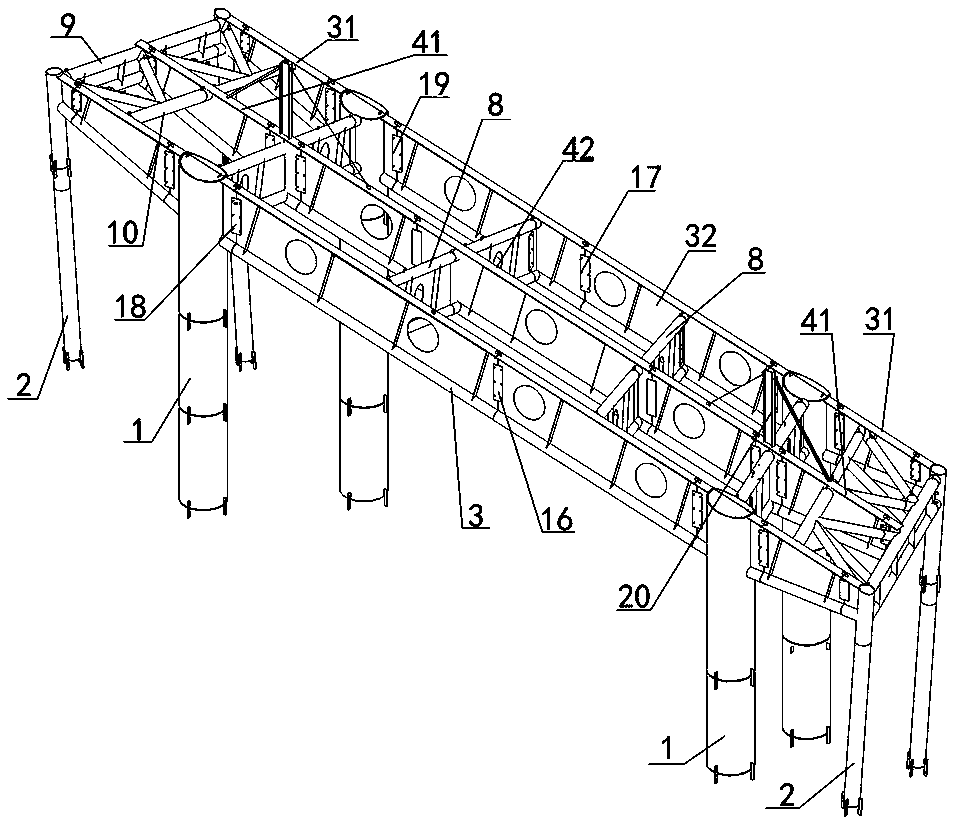

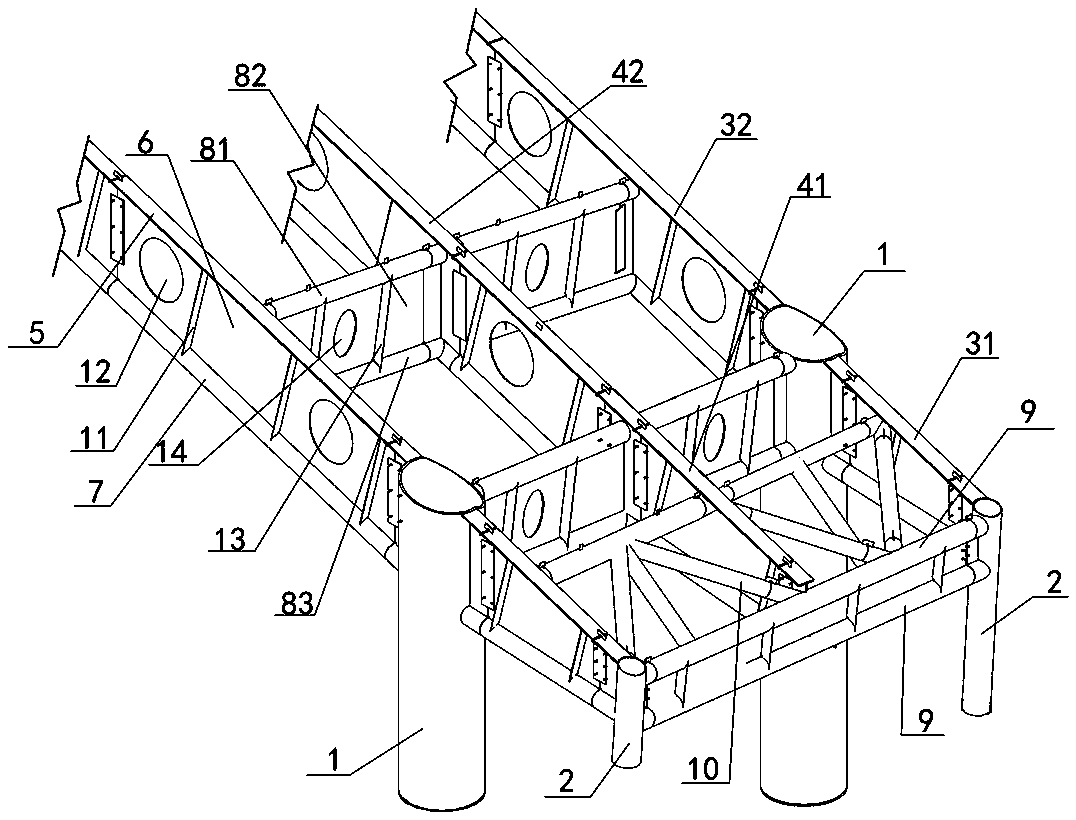

[0057] Examples see Figure 1-6 As shown, a long-span multi-section composite truss roof structure system includes structural columns and roof trusses connected to the structural columns.

[0058] The structural column is connected to two longitudinal ends of the roof truss, and the structural column is divided into a nearer central column 1 and a farther side column 2 according to the mid-span distance from the roof truss.

[0059] The roof trusses include longitudinal main trusses and transverse secondary trusses.

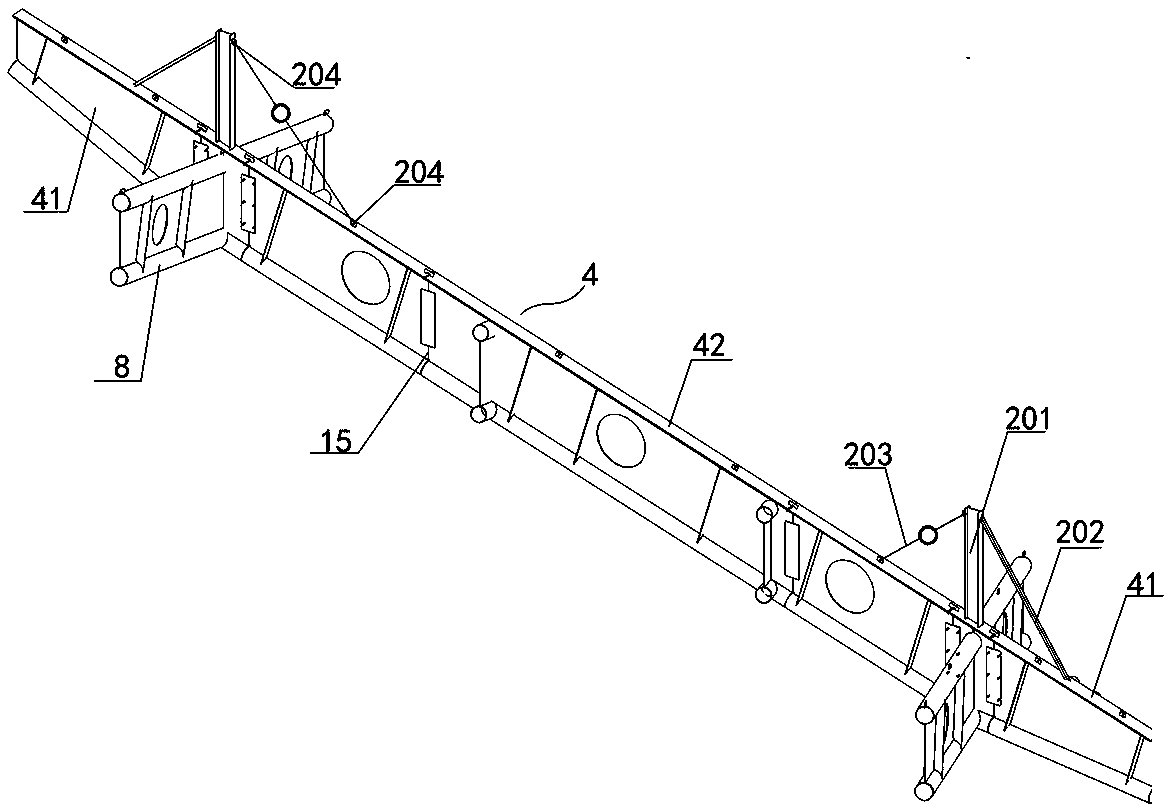

[0060] There are three main trusses arranged in parallel at intervals, including side main trusses 3 on both sides and middle main trusses 4 in the middle.

[0061] The side main truss 3 is divided into three sections by the structural columns, fixedly connected between the longitudinal columns of the structural columns, which are respectively two side side sections 31 and a side middle section 32, and the connection between the center columns 1 is the side sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com