Large-area preparation method for zinc oxide nanorod array

A zinc oxide nanorod, large-area technology, applied in the direction of zinc oxide/zinc hydroxide, metal material coating process, coating, etc., can solve the problems of high cost and poor production repeatability of zinc oxide nanorod arrays, and achieve improved Reproducible, low-cost, and simple-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

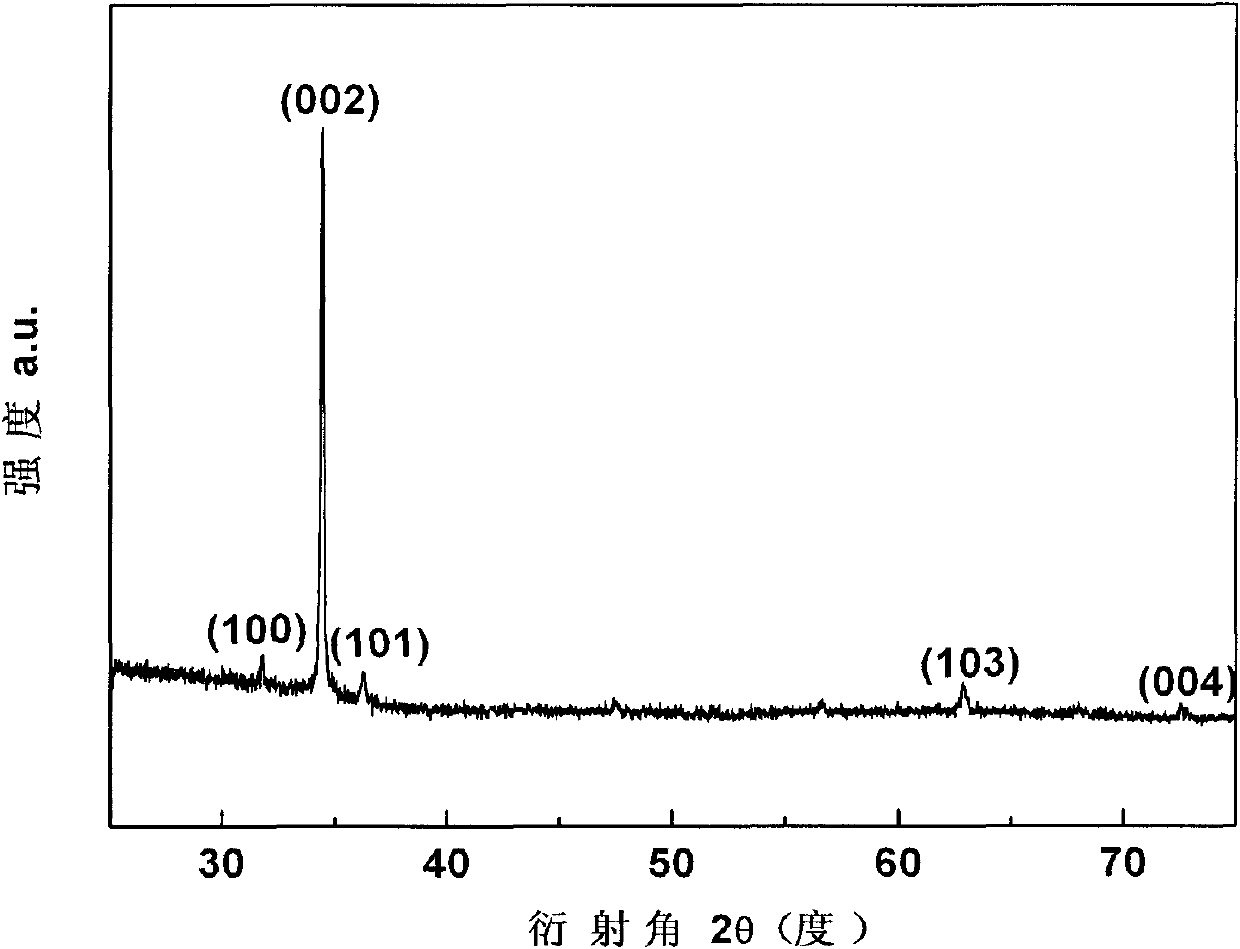

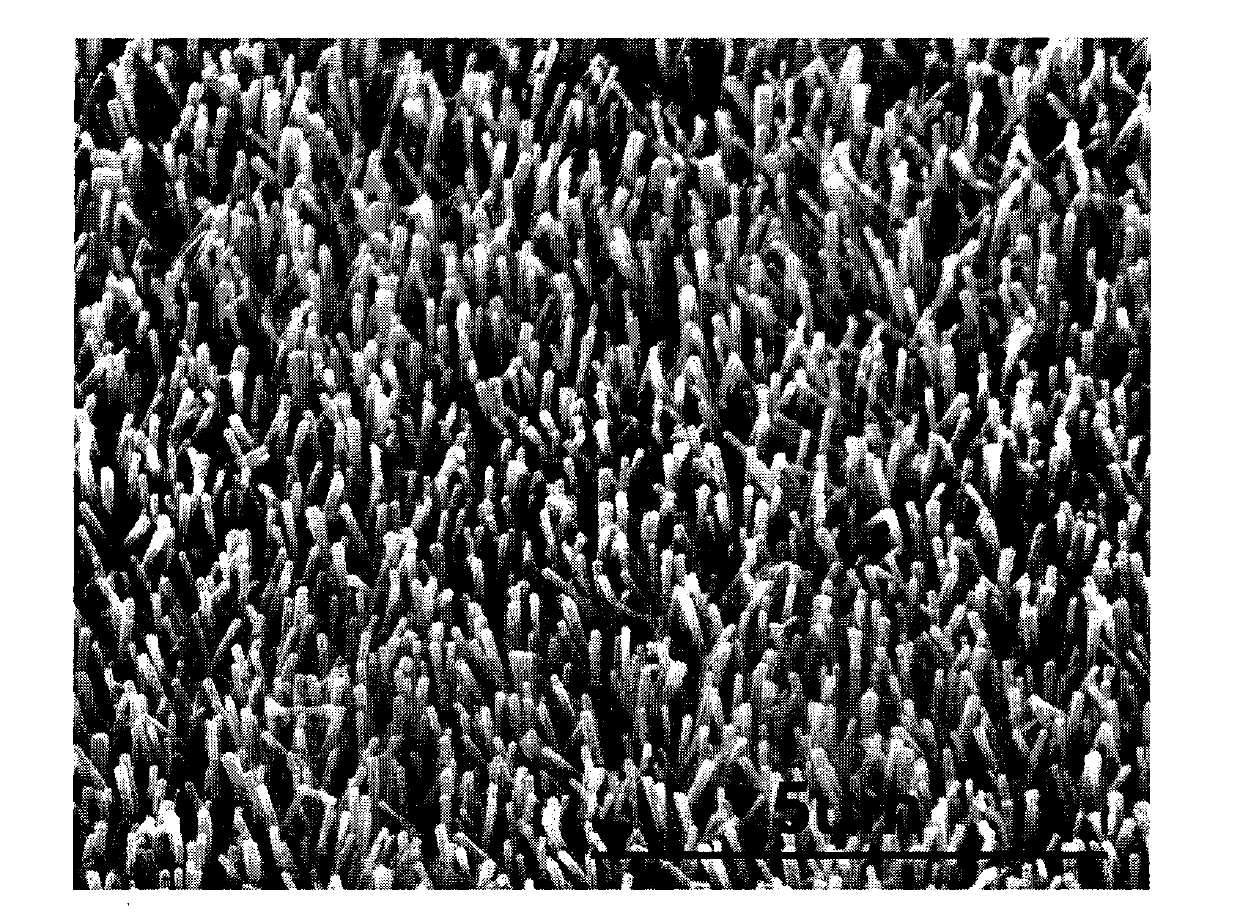

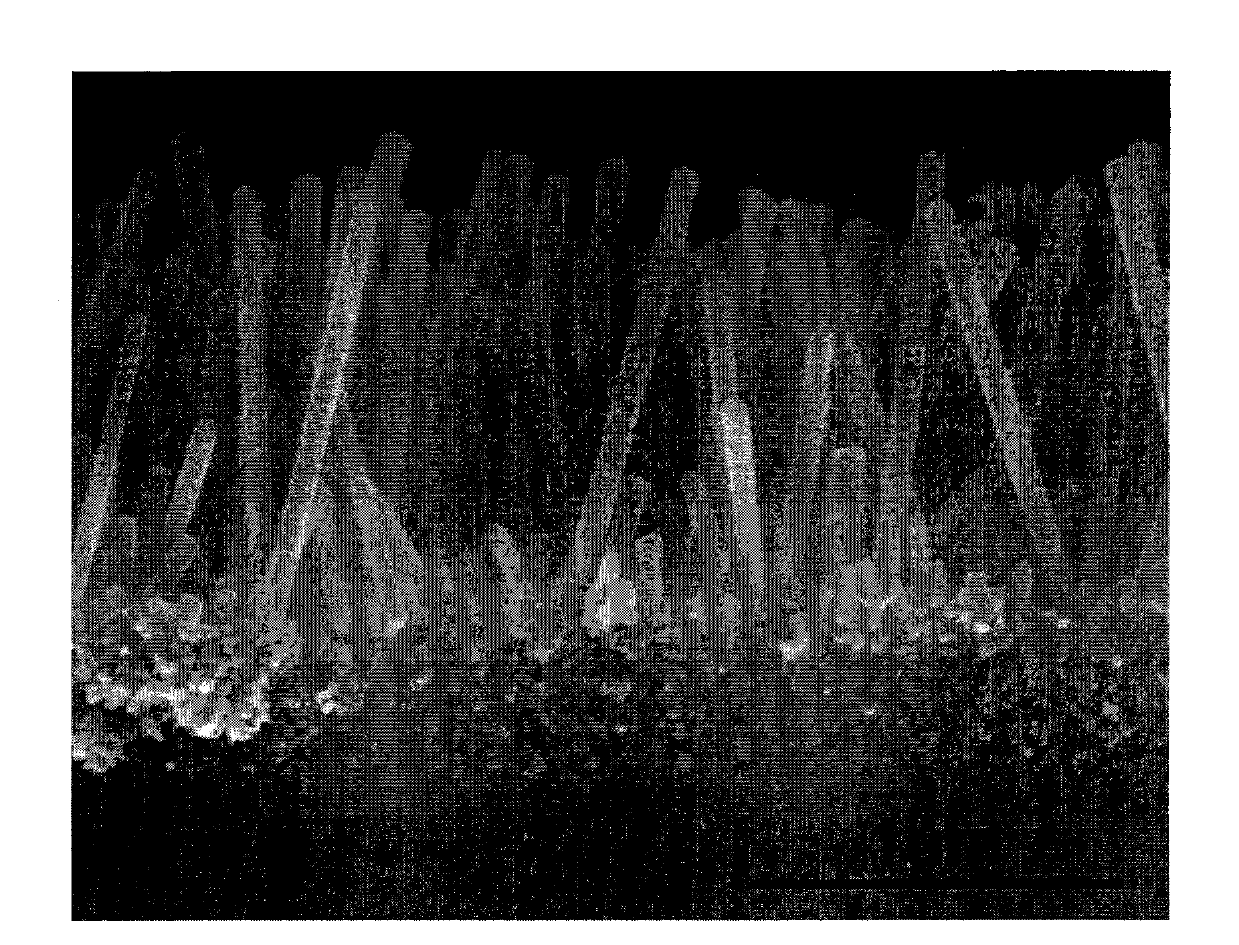

[0031] The method for preparing a large-area zinc oxide nanorod array with good orientation and high density includes four steps of configuring sol, cleaning substrate, dipping-pulling coating and crystallization heat treatment. Zinc acetate dihydrate (C 4 h 6 o 4 Zn 2(H 2 O)) and equimolar ratio of monoethanolamine (C 2 h 7 NO) was dissolved in ethylene glycol methyl ether and stirred at 65°C for 30 minutes, then a small amount of aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) put into this solution, continue to stir for 10min to obtain clear pale yellow sol. The concentration of zinc acetate dihydrate in ethylene glycol methyl ether is 1.5 mol / L, and the molar ratio of zinc acetate dihydrate to aluminum chloride hexahydrate is 96:4. A glass slide (soda-lime-glass) with a surface size of 25×76mm was put into acetone-distilled water-absolute ethanol-distilled water in sequence for ultrasonic cleaning for 10 minutes, and dried and stored after cleaning. The substrate is...

Embodiment 2

[0033] According to the preparation method of Example 1, as long as the pulling speed is increased from 1.2 cm / min to 2.4 cm / min, an array of zinc oxide nanorods with a diameter of 85 nm, a length of 450 nm, and an aspect ratio of 5 is prepared.

Embodiment 3

[0035] According to the preparation method of Example 1, as long as the pulling speed is increased from 1.2 cm / min to 6.0 cm / min, an array of zinc oxide nanorods with a diameter of 85 nm, a length of 600 nm, and an aspect ratio of 7 is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com