Preparation method and application of surface SiO2 load modified ardealite fibers papermaking filler

A technology of phosphogypsum and surfactant, which is applied in fiber raw material processing, surfactant addition, papermaking, etc., and can solve problems such as cost disadvantages, low paper retention rate, and easy powder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

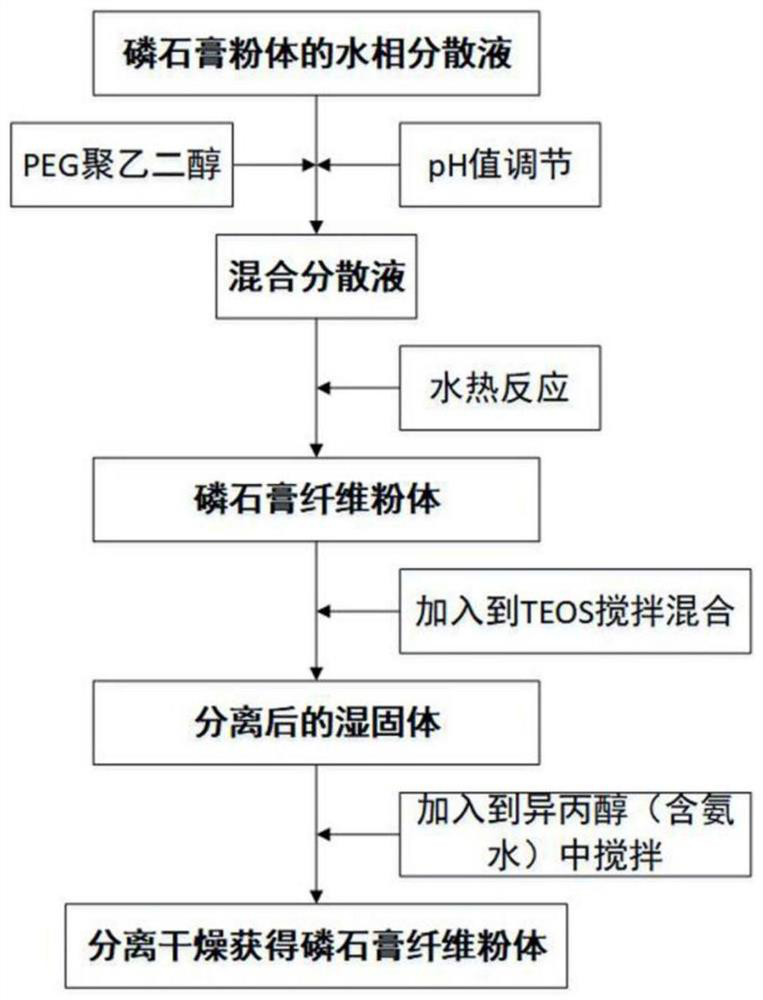

[0032] Example 1, see figure 1 .

[0033] (1) Preparation of phosphogypsum fiber powder. Take an appropriate amount of phosphogypsum powder and disperse it in an appropriate amount of water to obtain a suspension with a solid-to-liquid mass ratio of 1:10. Use HCl and NaOH to adjust the pH value of the above dispersion system, and the value is 6.2.

[0034] (2) Subsequently, a surfactant polyethylene glycol (PEG) 200 is added to the system in step (1), and the addition ratio of the surfactant is 1.2 wt%. Subsequently, the above-mentioned phosphogypsum fiber material was prepared through a hydrothermal reaction system, the hydrothermal reaction temperature was 120° C., and the reaction time was 2 hours.

[0035] (3) SiO2 surface loading modification of phosphogypsum fibers. The SiO2 shell loading was achieved by alkaline hydrolysis of tetraethylorthosilicate (TEOS). The steps are: under the protection of a nitrogen atmosphere, add an appropriate amount of phosphogypsum fibe...

Embodiment 2

[0038] Example 2, see figure 1 .

[0039] (1) Preparation of phosphogypsum fiber powder. Take an appropriate amount of phosphogypsum powder and disperse it in an appropriate amount of water to obtain a suspension. The mass ratio of solid to liquid is 1:15. Use HCl and NaOH to adjust the pH value of the above dispersion system, and the value is 7.0.

[0040] (2) Subsequently, a surfactant polyethylene glycol (PEG) 2000 is added to the system in step (1), and the addition ratio of the surfactant is 2.0 wt%. Subsequently, the above-mentioned phosphogypsum fiber material was prepared through a hydrothermal reaction system, the hydrothermal reaction temperature was 140° C., and the reaction time was 6 hours.

[0041](3) SiO2 surface loading modification of phosphogypsum fibers. The SiO2 shell loading was achieved by alkaline hydrolysis of tetraethylorthosilicate (TEOS). The steps are: under the protection of a nitrogen atmosphere, add an appropriate amount of phosphogypsum fib...

Embodiment 3

[0044] Example 3, see figure 1 .

[0045] (1) Preparation of phosphogypsum fiber powder. Take an appropriate amount of phosphogypsum powder and disperse it in an appropriate amount of water to obtain a suspension. The mass ratio of solid to liquid is 1:40. Use HCl and NaOH to adjust the pH value of the above dispersion system, and the value is 8.0.

[0046] (2) Add surfactant polyethylene glycol (PEG) 200-20000 to the system in step (1) subsequently, and the adding ratio of surfactant is 4.5wt%. Subsequently, the above-mentioned phosphogypsum fiber material was prepared through a hydrothermal reaction system, the hydrothermal reaction temperature was 150° C., and the reaction time was 12 hours.

[0047] (3) SiO2 surface loading modification of phosphogypsum fibers. The SiO2 shell loading was achieved by alkaline hydrolysis of tetraethylorthosilicate (TEOS). The steps are: under the protection of a nitrogen atmosphere, add an appropriate amount of phosphogypsum fiber powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com