Roller abrasion resistance testing device for roller skate

A test device and wear resistance technology, which is applied in the field of roller skate wheel wear test devices, can solve the problems that the positioning accuracy is easily affected by human factors, the measurement results have large deviations, and it is difficult to meet the accuracy requirements, so as to achieve perfect detection capabilities , Improving the detection level and improving the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

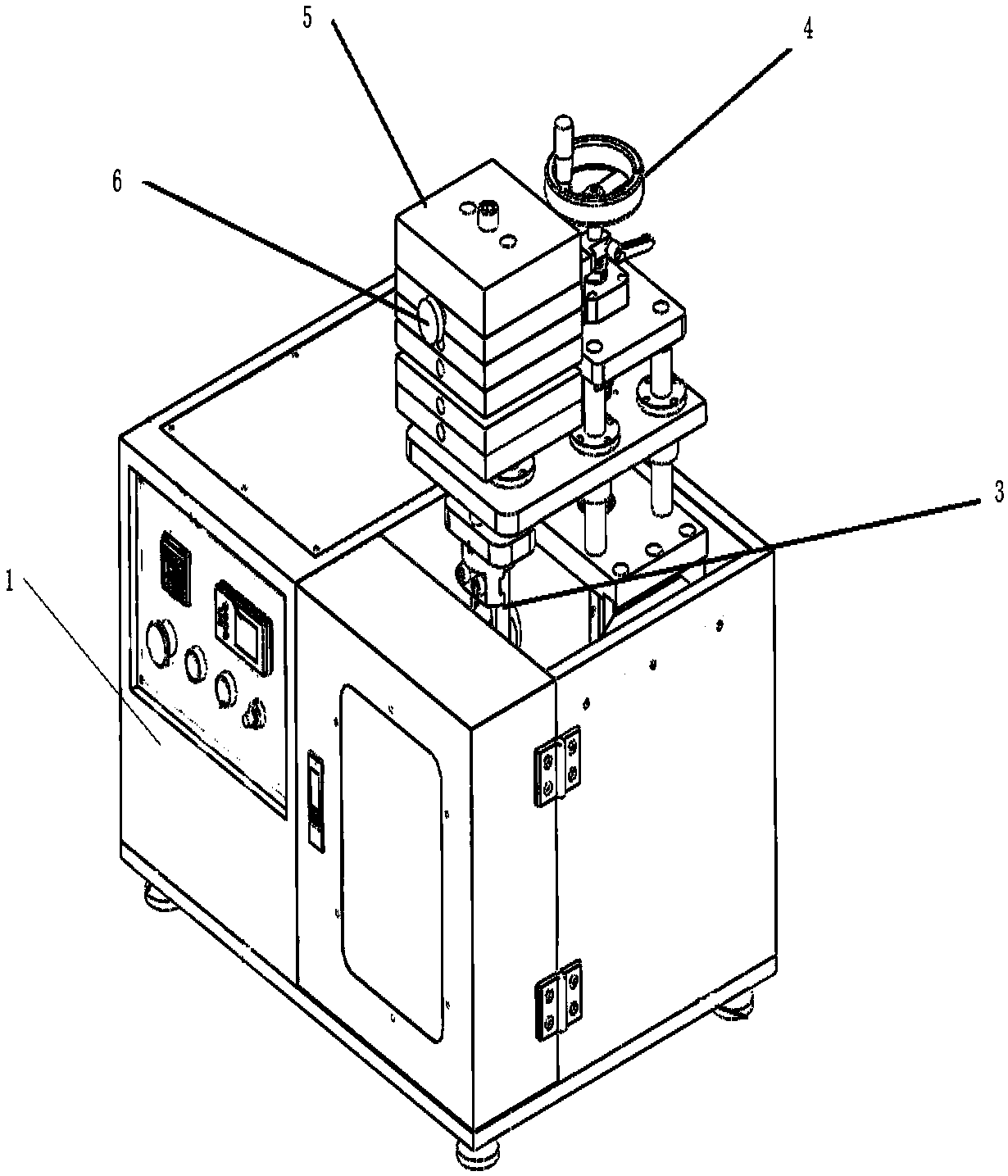

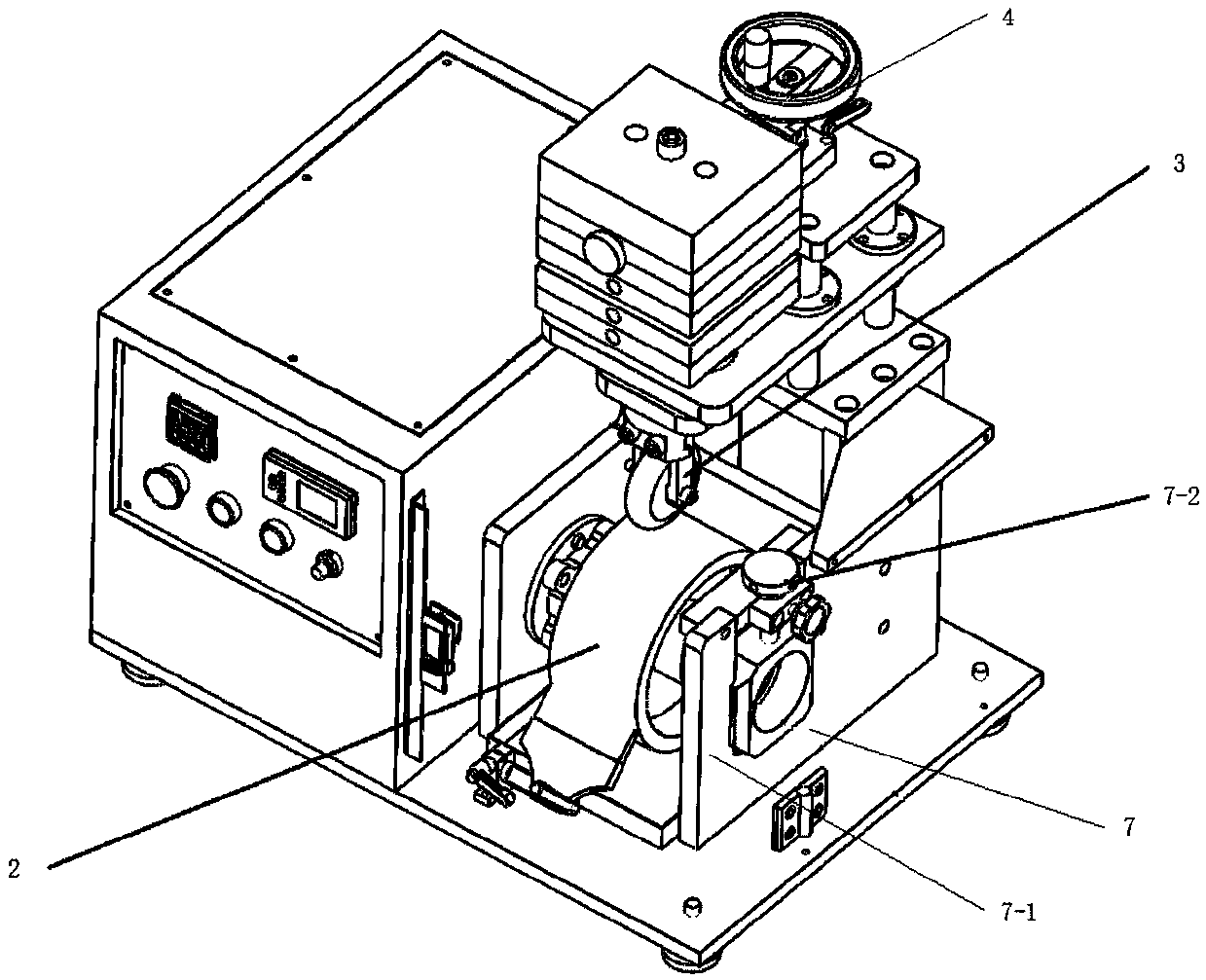

[0021] like figure 1 and figure 2 As shown, the wheel wear resistance test device provided by the present invention includes an electric control cabinet 1, a grinding wheel 2, a wheel fixture 3, a wheel up and down adjustment rod 4 and a test weight 5. The electric control cabinet 1 is internally provided with a motor, A control panel is arranged outside the electric control cabinet 1, and the rotational speed and time of the motor are controlled through the control panel. The rotating shaft of the motor is connected with the shaft of the grinding wheel 2. Connected with the wheel up and down adjustment rod 4, the test weight 5 is set on the platform of the electric control cabinet 1, the test weight 5 is a set of weights with different standard weights, and each weight is provided in the horizontal direction The through hole, the weight is connected with the wheel up and down adjusting rod 4 through the latch 6 penetrating through the through hole;

[0022] The horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com