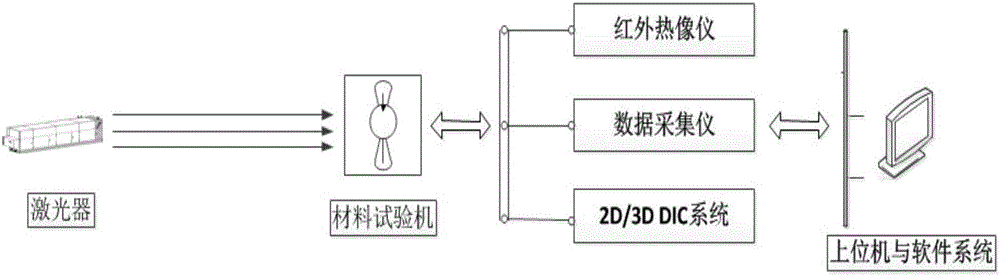

Material high temperature mechanical property test system and method based on laser irradiation heating

A technology of laser irradiation and high temperature mechanics, which is used in the application of stable tension/pressure to test the strength of materials, analyze materials, scientific instruments, etc. problems, to achieve the effect of comprehensive testing and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

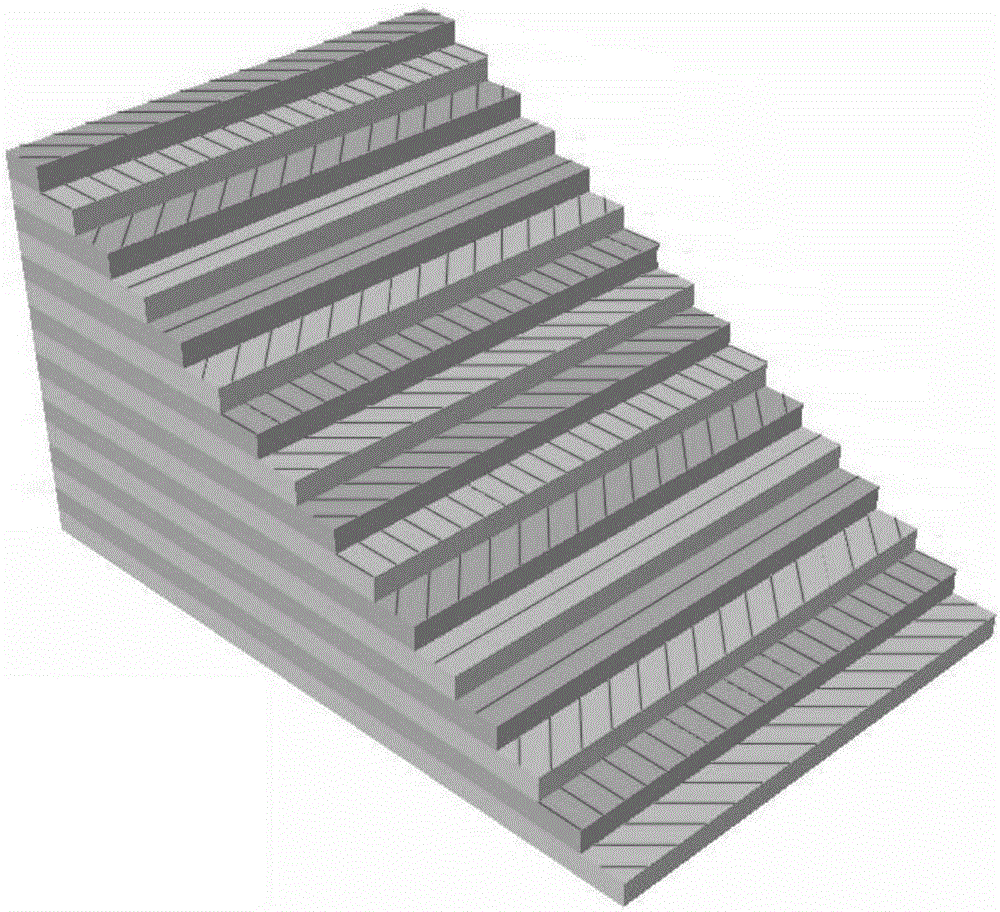

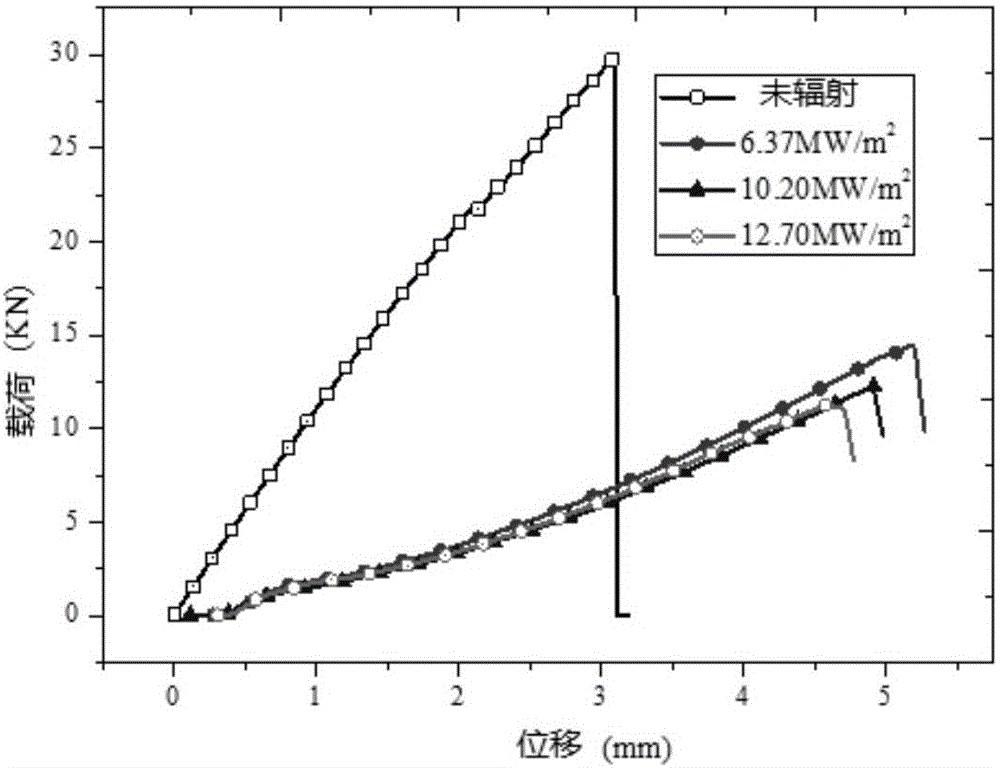

[0029] Using 2D-DIC system and electronic universal testing machine, the loading test is carried out on the sample material. There are two kinds of sample materials: carbon fiber reinforced composite laminates, T700 / BA9916 and CCF300 / BA9916, the layup method is [45° / 0° / -45° / 90°] 2S ; The surface damage effect and the material sample in the graph are CCF300 / BA9916; since the experimental results of sample T700 / BA9916 are similar to those of CCF300 / BA9916, they are not listed one by one.

[0030] The spot is in the middle of the sample material, and the laser performs remote and non-contact heating on the sample material, and the tensile system on the electronic universal testing machine sequentially performs tensile loads on the sample material. The loads are 14.5kN, 12.2kN, and 11.3kN respectively Load and use a CCD camera for photographic sampling with a sampling frequency of 2 frames per second. At the same time, the ambient temperature data, local point temperature, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com