Wiring harness stretch performance detection device

A technology for testing devices and wire harnesses, which is applied in the direction of measuring devices, testing material ductility, strength characteristics, etc., can solve problems such as incomplete design of wire harness clamping and fixing devices, complicated testing equipment, inconvenient operation, etc., and achieve surface detail processing Unique, simple test device, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

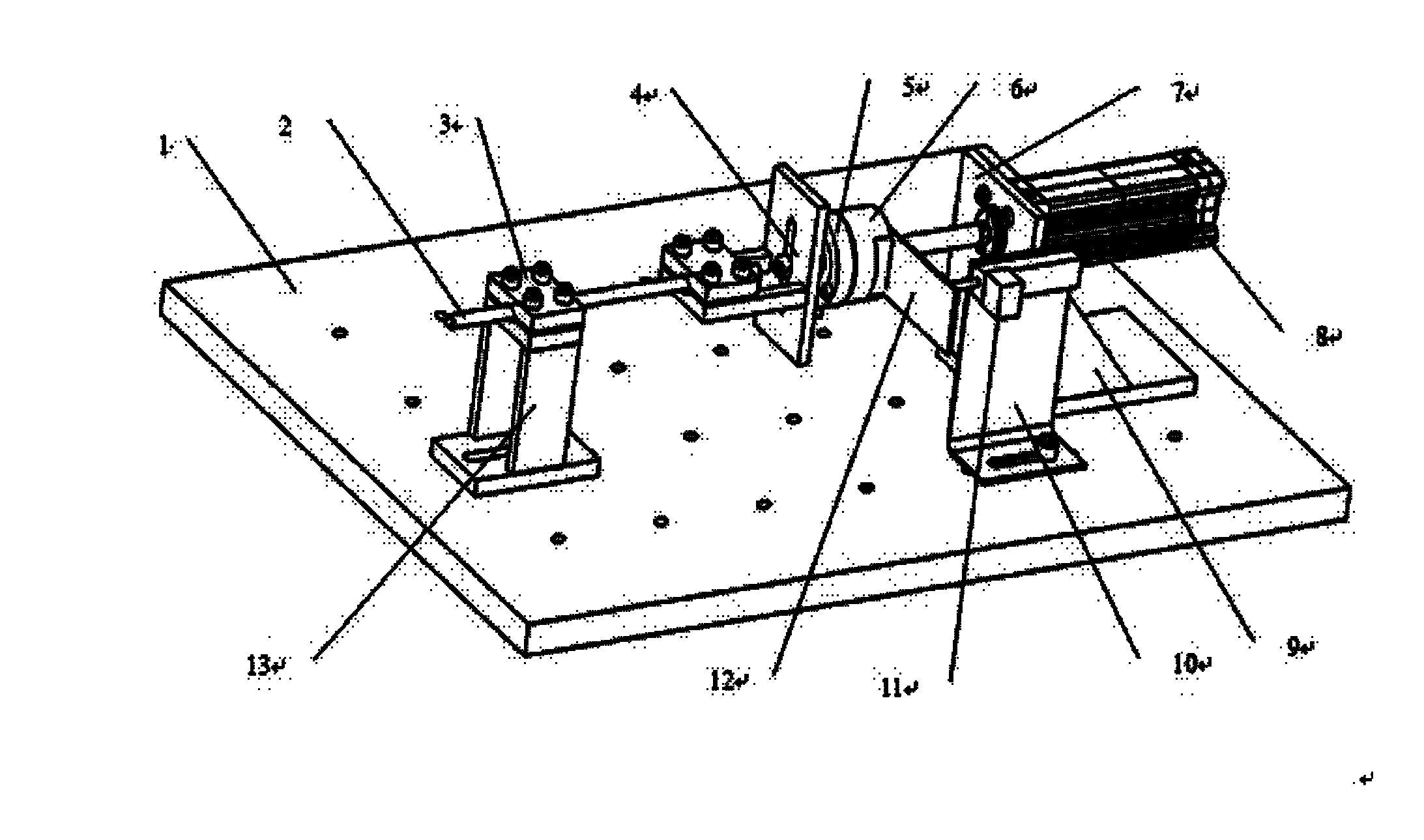

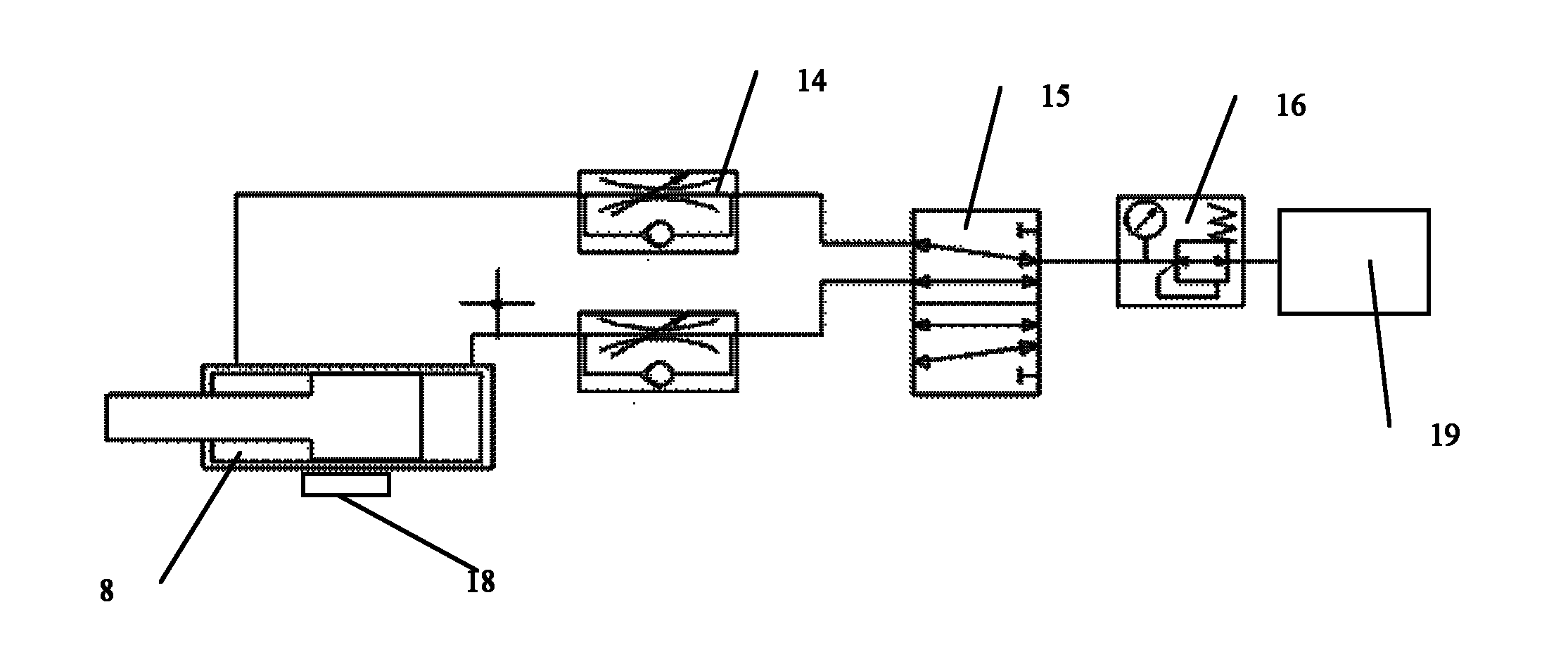

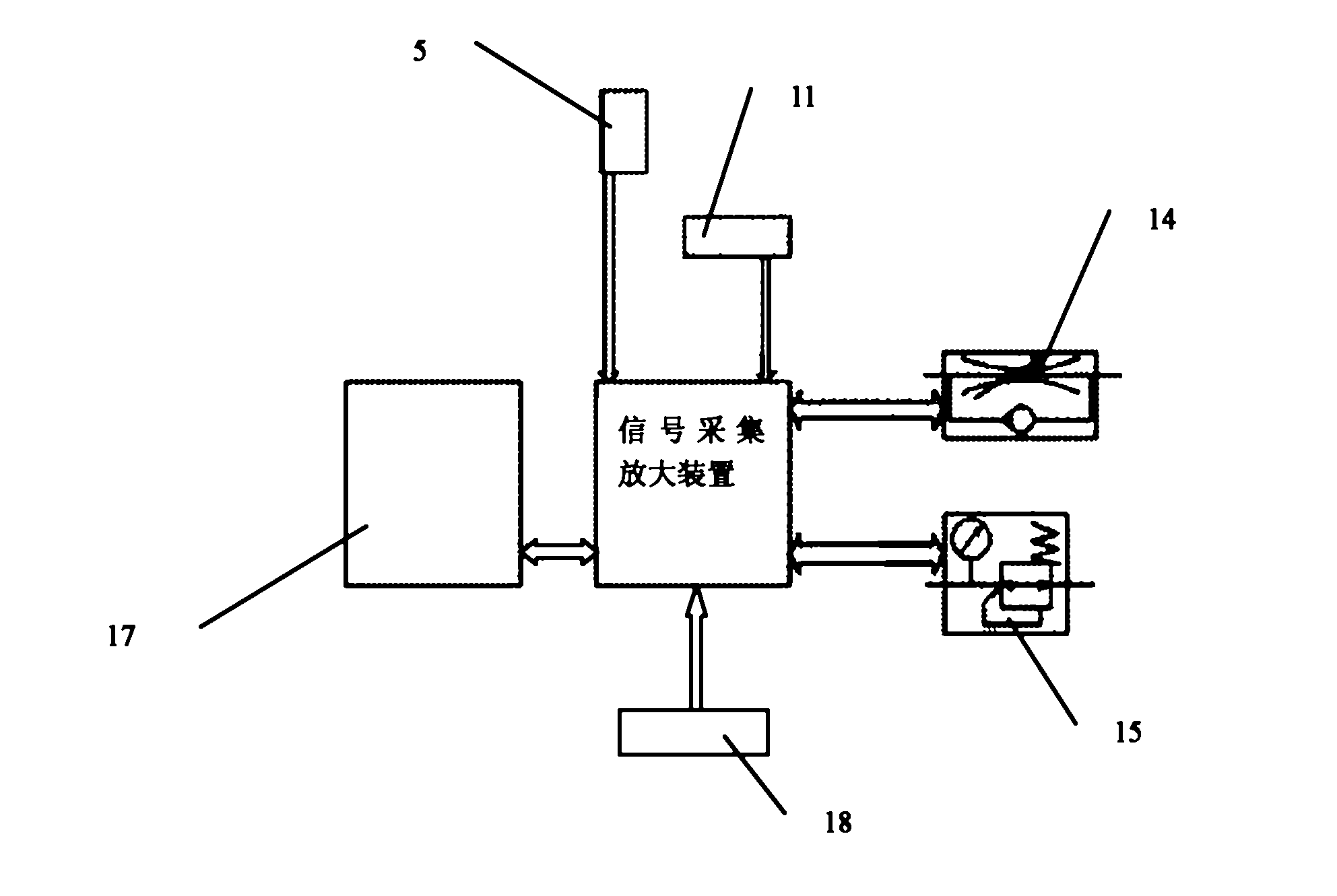

[0036] Such as figure 1 , figure 2 , image 3 As shown, the wire harness extensibility testing device of the present invention includes a tension loading mechanism, a clamping mechanism, and testing equipment.

[0037] The tension loading mechanism includes a high-pressure air source 19 , a double-acting cylinder 8 , a pressure regulating valve 16 , two speed regulating valves 14 , a reversing valve 15 , and a first support 9 . The first bracket 9 is fixedly installed on the working platform 1, and the connection seam of the double-acting cylinder 8 is fixedly installed on the first bracket 9 by four embedded hexagon socket head cap screws. The high-pressure gas source 19 communicates with the two-way acting cylinder 8 through a pipeline, and a pressure regulating valve 16, a reversing valve 15 and a speed regulating valve 14 are arranged on the communication pipeline. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com