Method of detecting an in-range failure of a brake pedal position sensor

A brake pedal and sensor technology, applied in the direction of brakes, brake action activation devices, brake components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

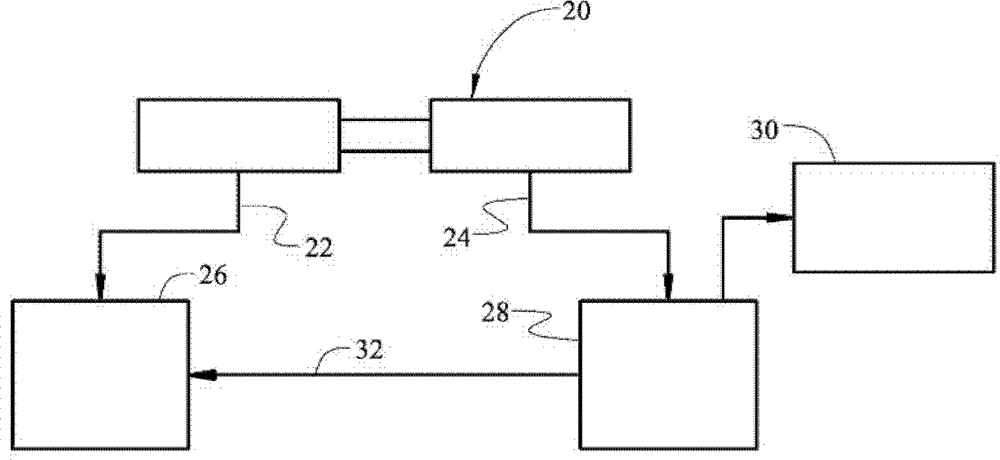

[0012] Reference is made to the drawings, wherein like reference numerals refer to like parts throughout the several views. The brake pedal position sensor is approximately figure 1 20 of them are shown. refer to figure 1 , the brake pedal position sensor 20 is configured to sense the position of a brake pedal (not shown) of a vehicle (not shown). The brake pedal position sensor 20 produces an electrical signal whose strength varies with the movement of the brake pedal. Accordingly, the signal from the brake pedal position sensor 20 varies with respect to changes in the position of the brake pedal.

[0013] The brake pedal position sensor 20 may include any brake pedal position sensor 20 capable of generating a first signal 22 and a second signal 24 , where each of the first signal 22 and the second signal 24 is indicative of the position of the brake pedal. The first signal 22 is directed to a controller 26 . Controller 26 may include, but is not limited to, an engine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com