Method for ground compression and heaping of large foundation piles for vertical compressive static load test in civil engineering

A technology of anti-compressive static load and civil engineering, which is applied in the direction of basic structure engineering, test of basic structure, construction, etc., and can solve problems such as increased risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

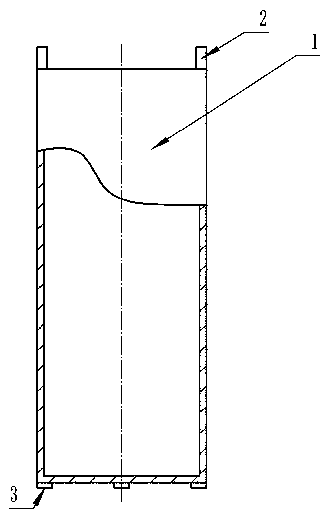

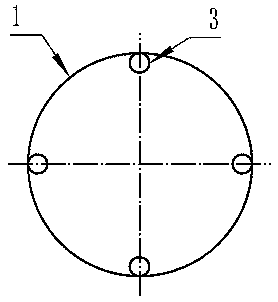

[0085] Embodiment 1: as Figure 1~3 As shown, the civil engineering described in the present embodiment uses the vertical anti-compression static load test large-scale foundation pile ground pressure heavy pile method, it is characterized in that it is carried out according to the following steps:

[0086] a. Build the ballast platform pier, and determine the vertical distance between the ballast platform, platform pier, main beam and test pile, and ensure that the detection jack, main beam, high secondary beam, low secondary beam and platform top and bottom plate steel plate and other equipment are installed in the exact spatial position, including the plane position and elevation;

[0087] b. Hoist the ballast stacked hollow tank column on the ballast platform in step a, and the hydraulic outrigger QFB non-standard jack under the base passes through the steel on the top layer of the platform to support the connecting beam 12 on the steel plate at the bottom of the platform o...

Embodiment 2

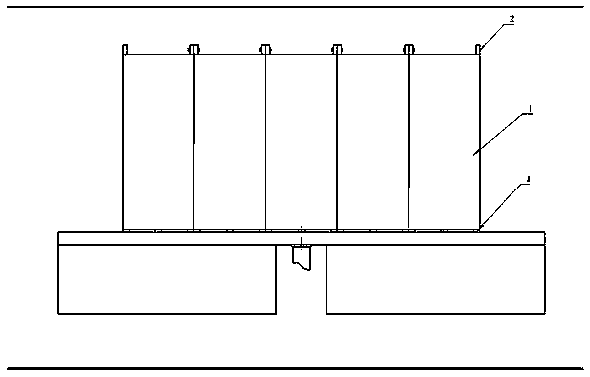

[0095] Embodiment 2: as Figure 4~5 As shown, the civil engineering described in this embodiment uses the method for ground pressure and heaping of large-scale foundation piles for vertical compressive static load test, which is similar to that of Example 1, except that the production of the pressure platform in the step a The process is as follows: fill the pier tank column 4 with bulk materials and then vibrate and level it. The bulk material must be 100 mm higher than the pier tank column and the main beam, and then lay steel plates. The transmission route, the thickness of the steel plate is 30 mm, but the lifting lug 11 of the tank column of the pier must be exposed to facilitate the connection with the low secondary beam 5; the high secondary beam is directly placed on the bottom steel plate of the platform on the tank column of the pier, and Put the low secondary beam on the cushion block after placing the cushion block, place a thin QFB non-standard jack between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com