A railway rail profile repair vehicle, its repair method and corresponding equipment

A rail and profile technology, which is applied in the field of railway rail maintenance, can solve the problems of small inertia, poor rail section accuracy and longitudinal smoothness, and large cutting vertical force, and achieve the effect of eliminating instantaneous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

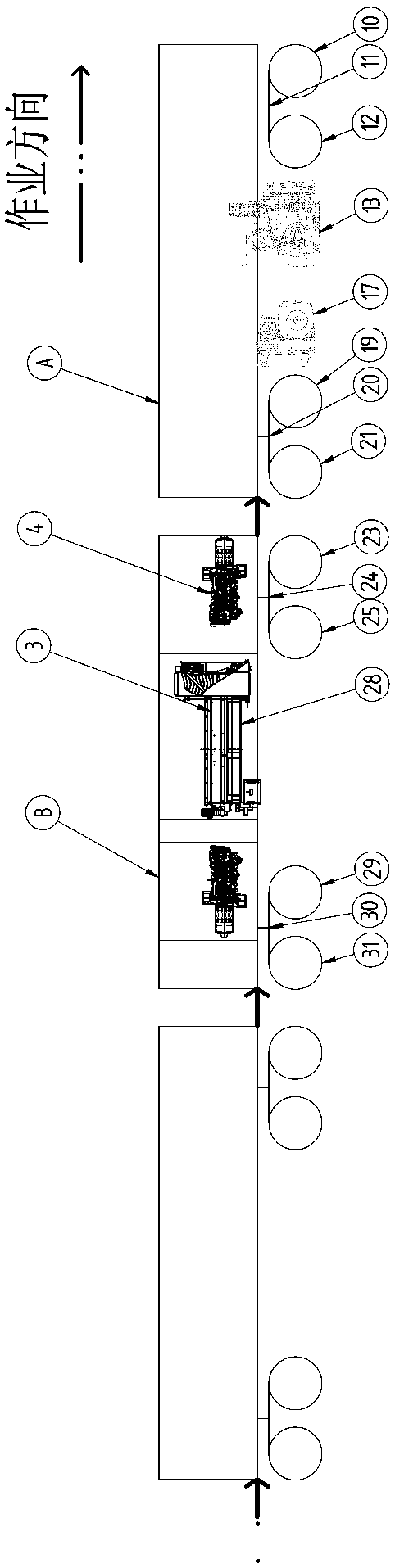

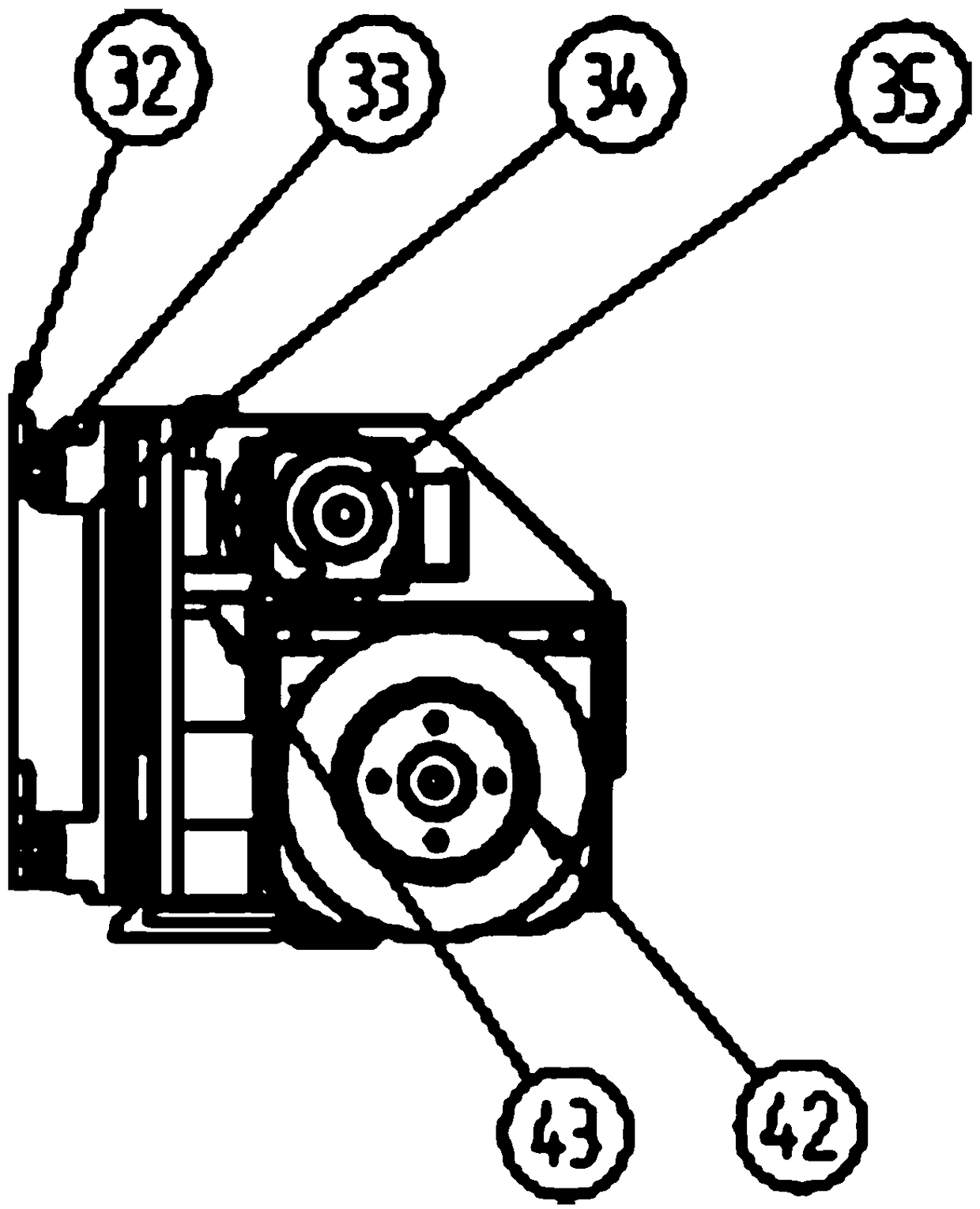

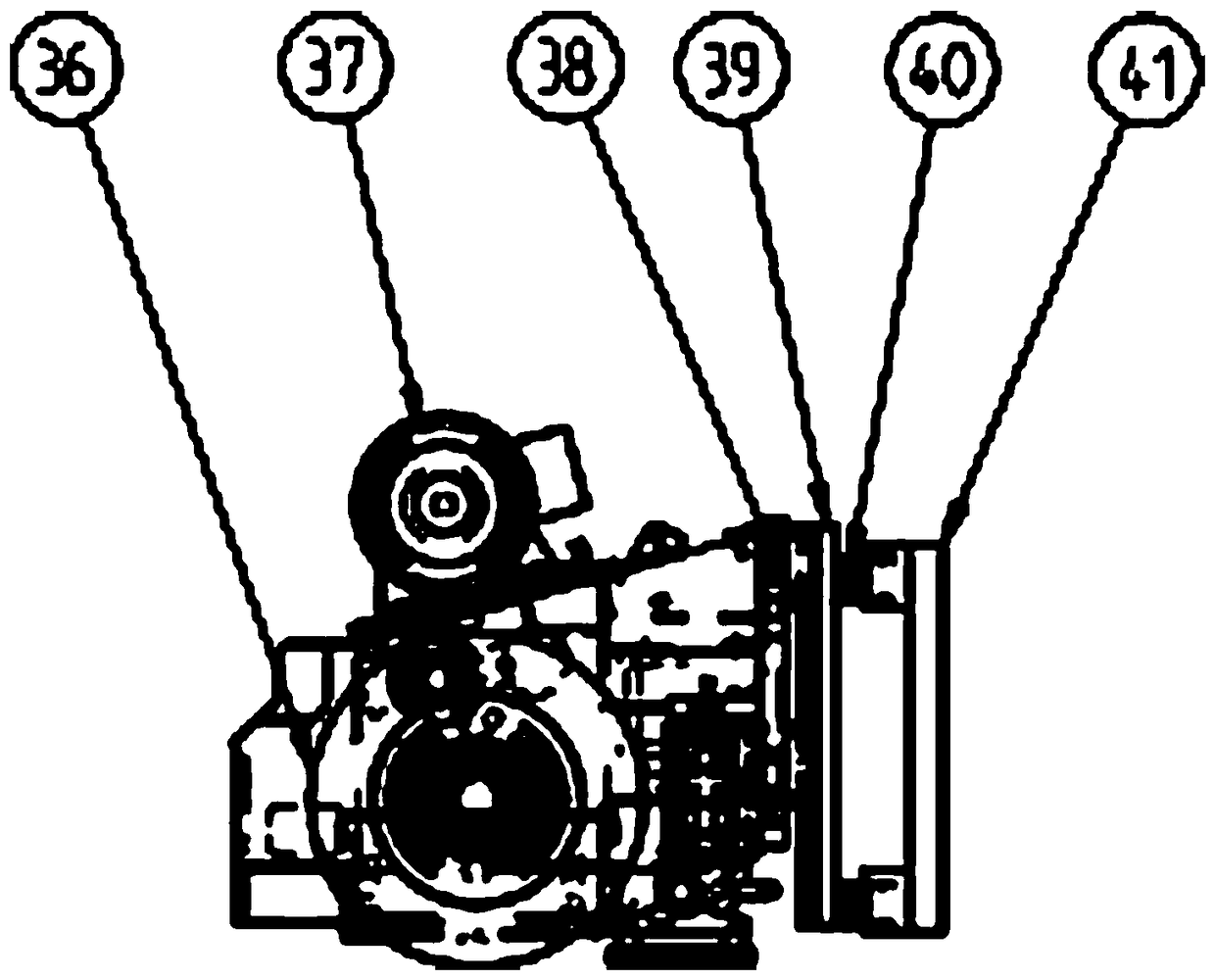

[0100] Embodiment 1.1: A rail profile repair vehicle, which includes a milling device X1 without grinding device, the milling device X1 realizes online dynamic shaping of the left and right rails; the milling device X1 includes a supporting base I, the supporting base The first Y-guiding rail Y1 and the second Y-guiding rail Y2 are installed on I, the first Z-guiding rail Z1 is installed on the substrate IJ1 of the first Y-guiding rail Y1, and the first Z-guiding rail Z1 is installed on the substrate IIJ2 of the second Y-guiding rail Y2. Two Z-guiding rails Z2, through the first Y-guiding rail Y1 and the first Z-guiding rail Z1, the Y-direction and Z-direction displacement of the left milling device on the left rail when shaping the rail profile can be realized, and through the second Y-guiding rail Y2 , The second Z guide rail Z2 can realize the Y-direction and Z-direction displacement when the right milling device located on the right rail is shaping the profile of the rail. ...

Embodiment 12

[0101] Embodiment 1.2: A rail profile refurbishment car, the same as embodiment 1.1, the difference is that it also includes a second set of milling device X2, and the structure of the second set of milling device X2 is the same as that of the milling device X1, such as Figure 9 As shown, the second set of milling devices X2 and the first set of milling devices X1 are arranged symmetrically with respect to the Y-direction center line of the vehicle frame, and are arranged below the vehicle frame.

Embodiment 13

[0102] Embodiment 1.3: A rail profile repair car, the same as Embodiment 1.2, the difference is that it also includes a third set of milling device X3, and the structure of the third set of milling device X3 is the same as that of the milling device X1. Three sets of milling devices X3 are arranged behind the first set of milling devices X1 and the second set of milling devices X2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com