Unit for production of track elements

A technology for equipment and components, which is applied in the field of equipment for manufacturing driving road components, and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

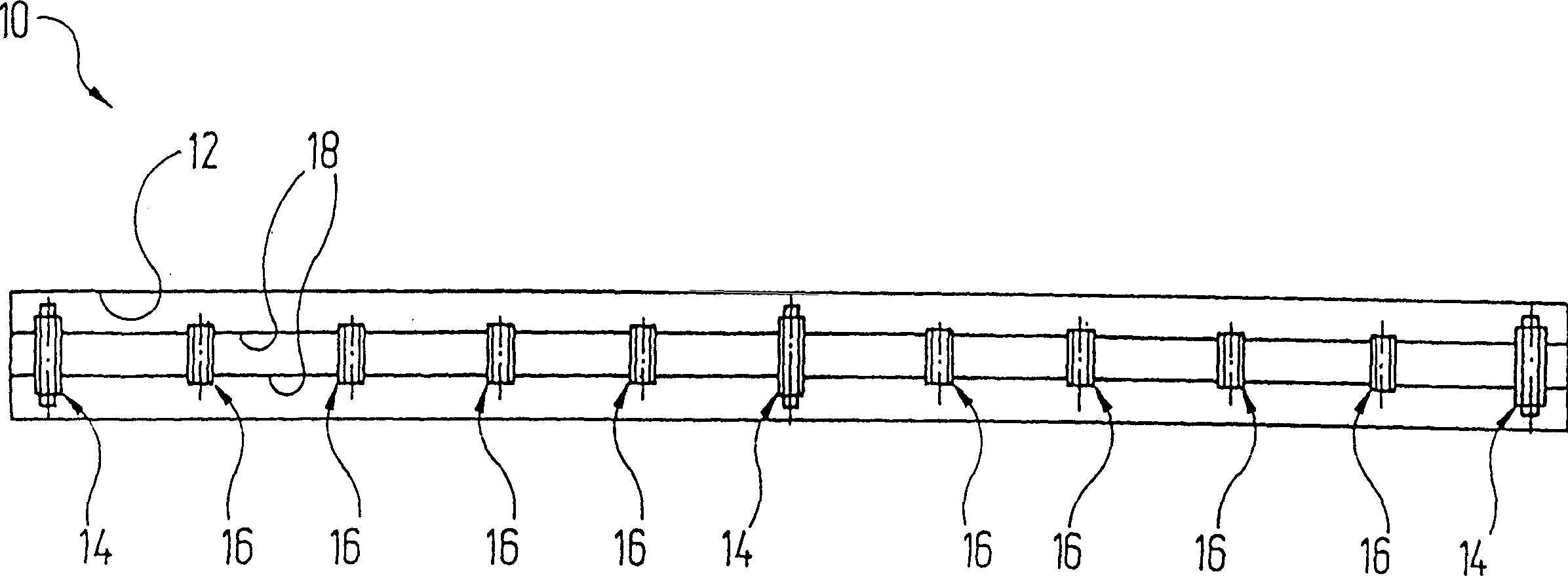

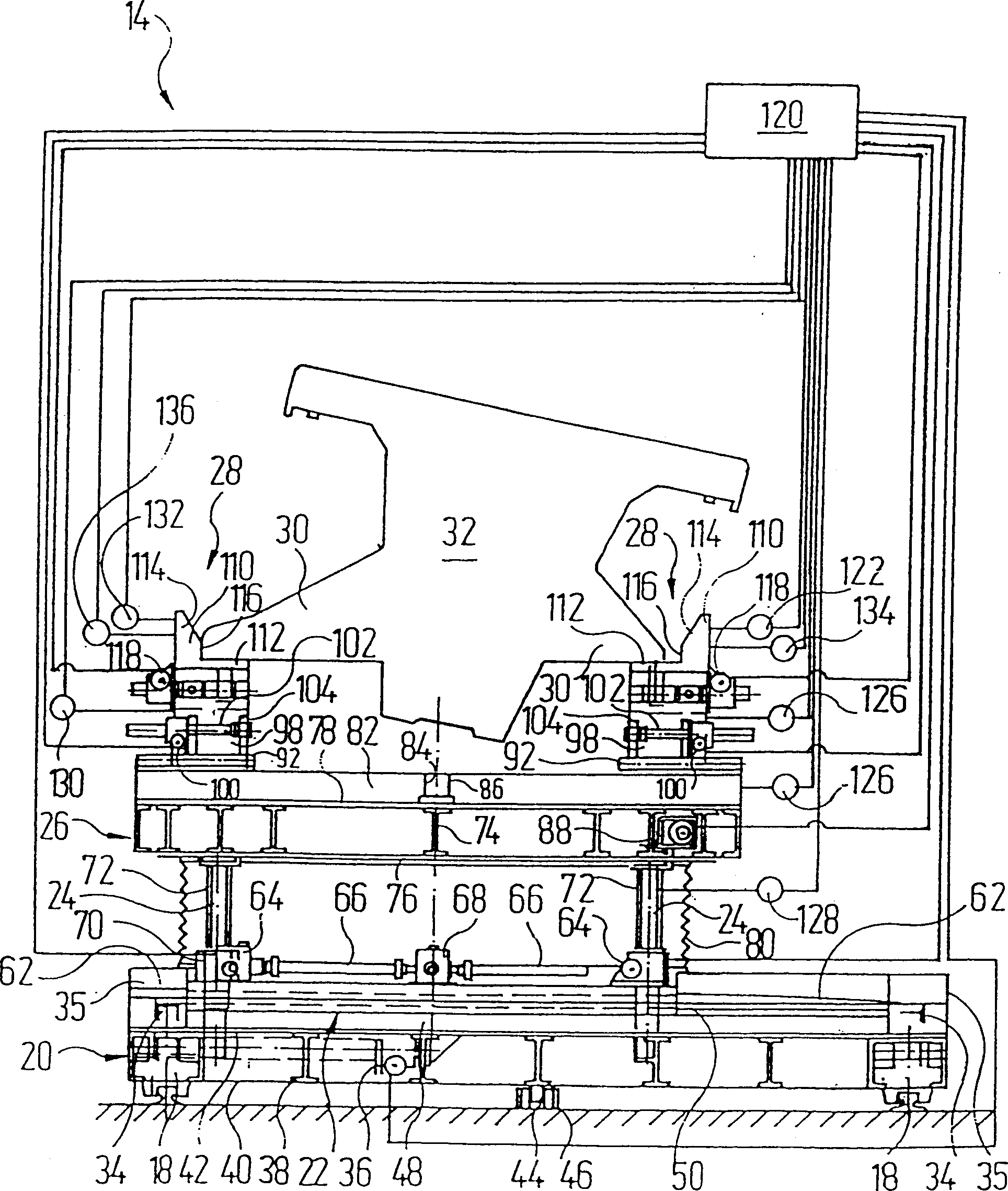

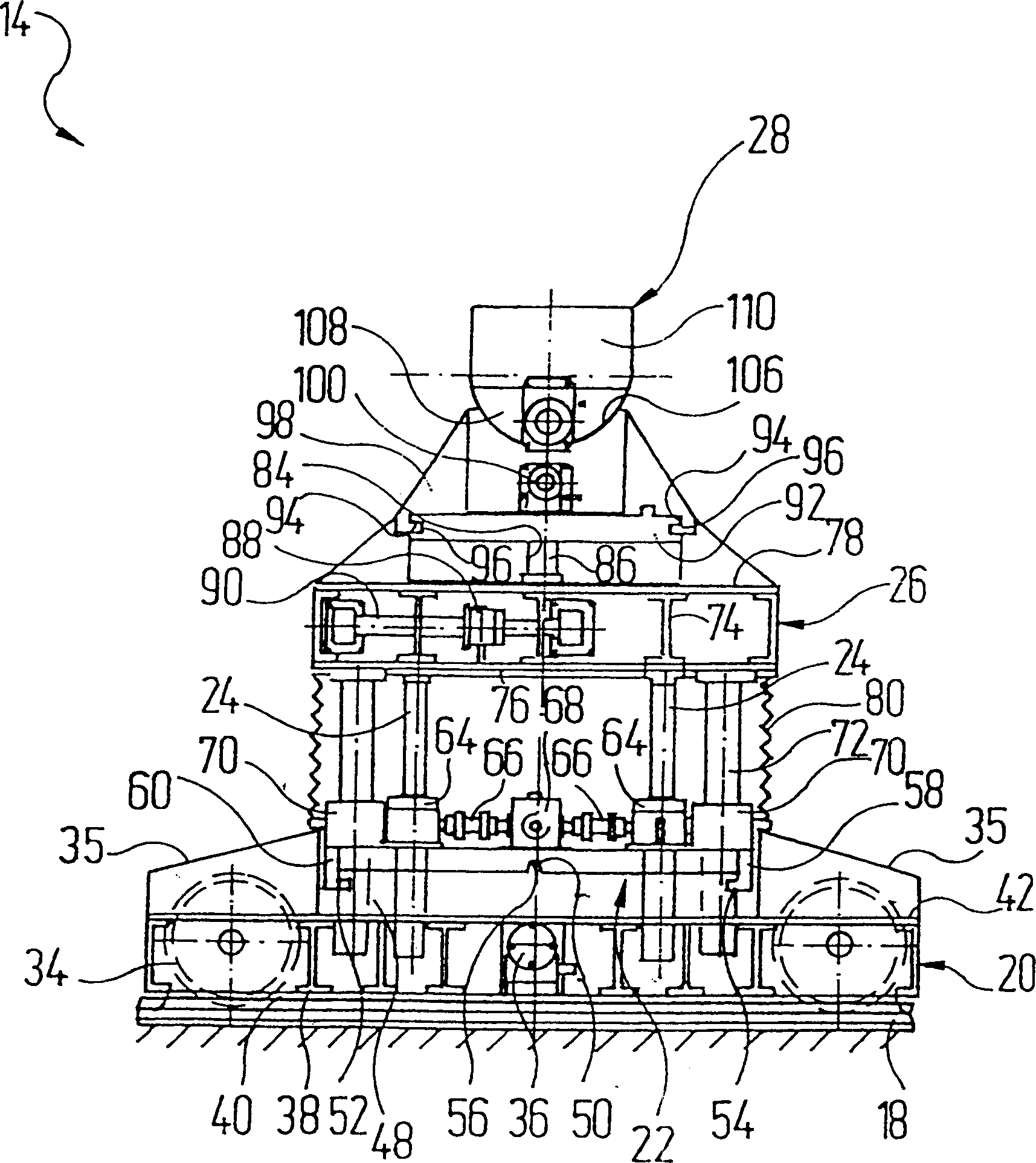

[0027] Equipment for the manufacture of driving pavement elements in figure 1 The whole is indicated by the reference symbol 10 . It comprises an elongated, rectangular depression 12 in plan view in the ground, in which a total of 11 holding devices are arranged along its length.

[0028] Each clamping device at each end of the well 12 as well as the intermediate clamping devices are formed as main support and receiving devices 14 . The clamping devices arranged between two such main bearing and receiving devices 14 are designed as clamping and damping devices 16 . The length of dimple 12 is slightly greater than a running road surface element (in figure 1 not shown in the length). The distance between each clamping device and between the main supporting and receiving device 14 and the clamping and damping device 16 is figure 1 All are equivalent in the shown embodiments. However, they can also vary depending on the type of running surface element to be produced. For thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com