Efficient relining manipulator

A manipulator, high-efficiency technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of poor quality of glass panel processing, poor cleanliness of glass panels, low degree of automation, etc., to achieve stable operation, ingenious design, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

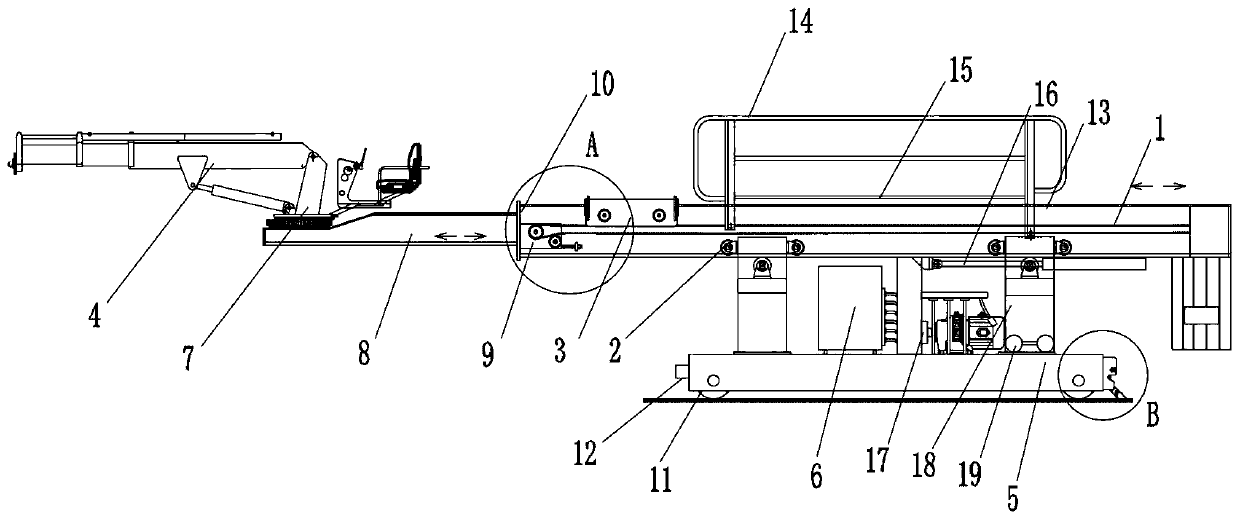

[0038] The top of the cart drive system 5 is provided with a track-type drive motor 17, and both sides of the upper end surface of the cart drive system 5 are provided with tracks matching the track-type drive motor 17, and the track-type drive motor 17 is driven in the track with the cart. The system 5 is flexibly connected, and drives the frame system 1 and the crane system 7 to move back and forth on the cart drive system 5 through the rail-type drive motor 17. This form runs smoothly and has no noise. When the crane 31 is working, the rail-type drive The motor 17 is anchored to the cart drive system 5 rails to ensure that the present invention is more comfortable and quiet when in use, and reduces the vibration of the crane system 7 during work and use, thereby ensuring the stability of the work.

Embodiment 2

[0040] The upper end of the cart drive system 5 is provided with a trackless drive wheel 18, and two hydraulic motors 19 are provided on both sides of the trackless drive wheel 18, and the hydraulic motor 19 is flexibly connected with the cart drive system 5 through the trackless drive wheel 18 , the trackless driving wheel 18 adopts rubber wheels, and is driven by the hydraulic motor 19 on the paved road autonomously, and is driven by four hydraulic motors 19 wheels, which can realize turning in situ and walking in any direction, which is convenient for the staff to control the crane. The working angle and position of the system 7 are adjusted, and the wideness of the adjustment is guaranteed. The hydraulic motor 19 has strong driving force, no noise and no maintenance.

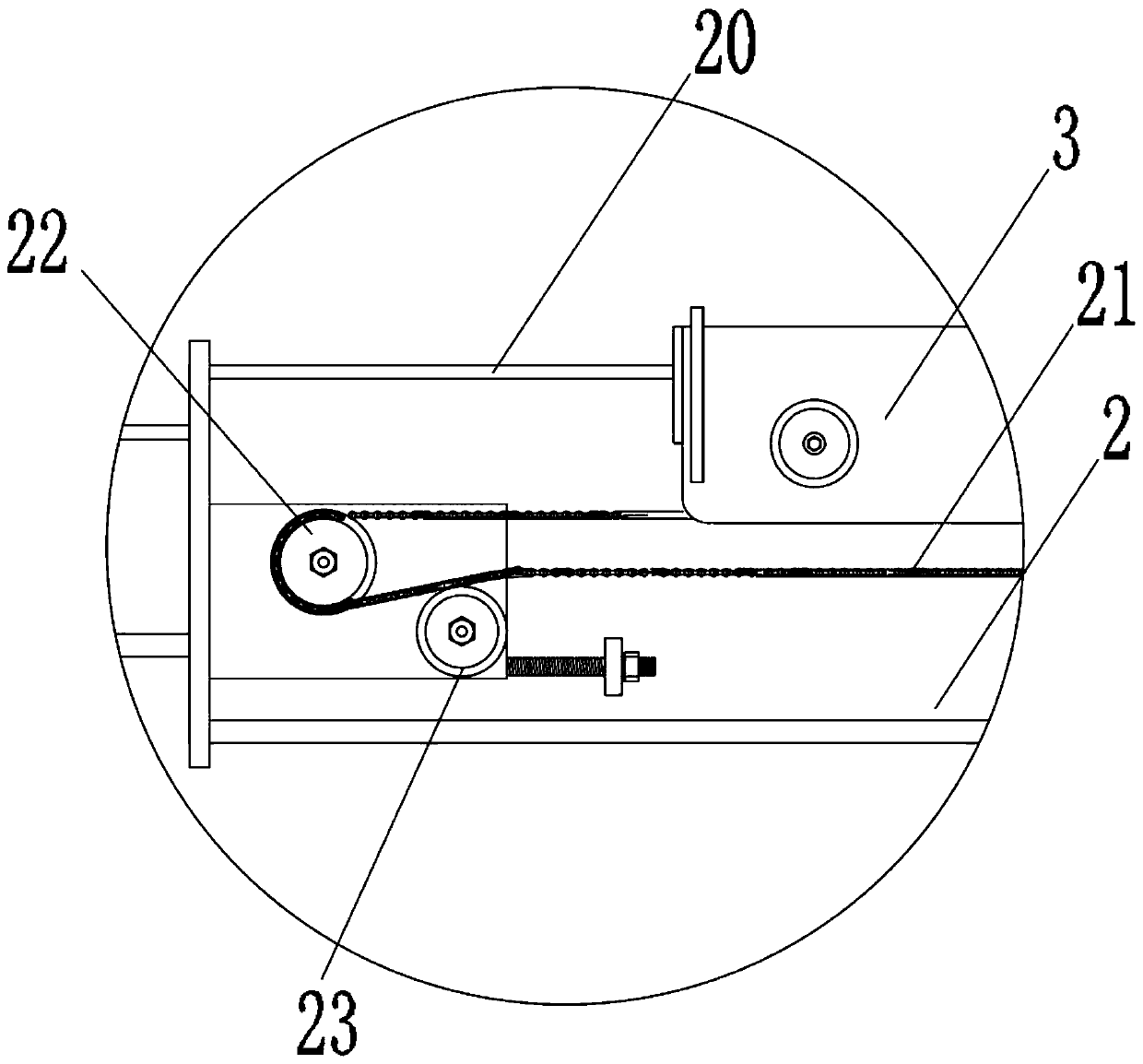

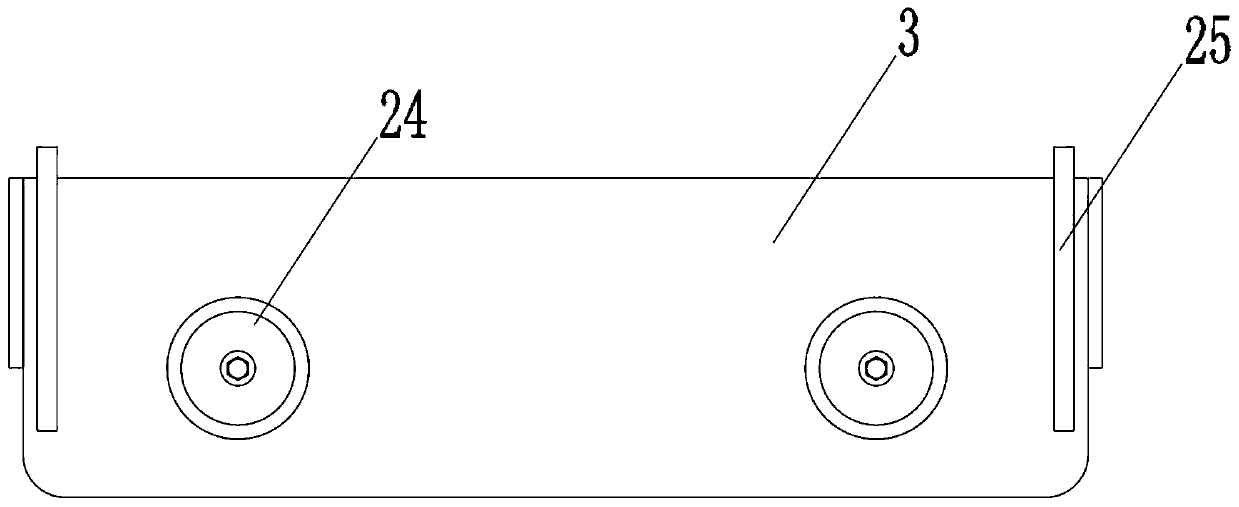

[0041] The upper end of the main beam running mechanism 2 is provided with a manipulator base 13, and both ends of the middle part of the main beam running mechanism 2 are longitudinally provided with a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com