An automatic weight-bearing contact device for color fastness testing based on temperature control in a closed environment

A closed environment, color fastness technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of automatic timing that cannot be controlled by temperature, and achieve the effect of precise control of test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

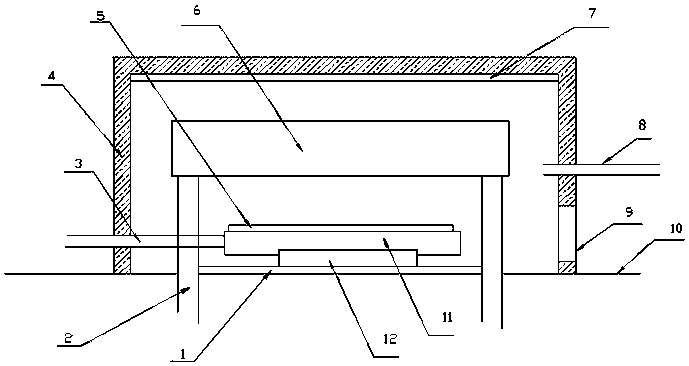

[0015] The present invention is described in further detail below in conjunction with accompanying drawing the composition of device and connection relationship:

[0016] Such as figure 1 Shown: an automatic load-bearing contact device for color fastness testing based on temperature control in a closed environment, including a bottom plate 10, a closed heat-insulation shell 4 buckled on the bottom plate, and an automatic load-bearing device is arranged on the bottom plate located in the cavity of the heat-insulation shell The testing mechanism, the automatic load testing mechanism is composed of a load detection platform 5 that can be translated and a flat test weight 6 that is used in conjunction with the load detection platform and can be lifted or pressed on the load detection platform. The weight 6 moves up and down through the lifting cylinders 2 arranged on the bottom plates on both sides of the object-loading detection platform. The object-loading detection platform 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com